The venture capital arm of German specialty chemicals company Evonik has invested in 3D printing software startup Castor Technologies. A 2018 beneficiary of the STANLEY+Techstars Accelerator, Castor Technologies has developed a platform enabling customers to asses part printability, select the best material for purpose, and attain cost and lead time estimates. In addition to financial investment, Evonik will contribute its material expertise to the platform, in return for insights into consumer needs and preferences. According to the company, the investment “enables Evonik to expand beyond selling materials” for the 3D printing industry.

“Castor occupies an exciting space in the 3D printing market, helping companies overcome the hurdles associated with adopting the technology,” commented Bernhard Mohr, head of activities at Evonik Venture Capital. “The investment perfectly complements our existing portfolio of 3D printing activities and is our second investment in Israel, one of the most active start-up ecosystems in the world.”

Evonik’s additive manufacturing strategy

Amidst competition from other leading chemical manufacturers, Evonik has built a comprehensive strategy for its role in the 3D printing industry. In February 2018, the company announced its intentions to increase production of its VESTOSINT range of 3D printing powders by 50%. Nearing completion in February of the following year the company reported that the expanded site, one of the largest in Germany, was worth around €400 million. In May 2019, it then closed a plant in Witten to focus more on the VESTOSINT site’s construction.

Externally, Evonik has also been lending its expertise to material development for emerging 3D printing technologies including Evolve Additive Solutions‘ Selective Thermoplastic Electrophotographic Process (STEP), and Cubicure Hot Lithography.

Finding additive manufacturing applications that make sense

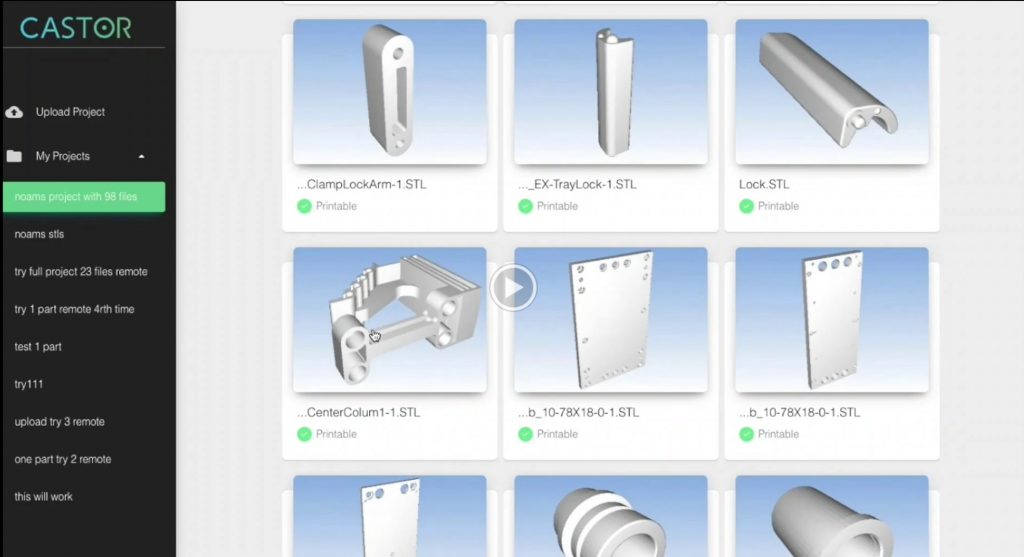

Castor has developed a software to help customers identify the break-even point for additive manufacturing versus traditional production methods. Enabling engineers to identify cost reductions and time savings, the platform facilitates adoption of 3D printing, as well as carving out a place for the technology within the wider manufacturing ecosystem. As explained by Thomas Große-Puppendahl, Evonik’s head of innovation growth in additive manufacturing, “With the software, broader adoption of 3D printing at a commercial scale becomes possible.”

The platform has been developed to complement CAD software, and allows the simultaneously analysis of large assemblies.

“Our vision,” Castor CEO Omer Blaier adds, is to be the manufacturers’ gateway to industrial 3D printing,

“Evonik’s expertise in 3D printed polymers combined with Castor’s ability to identify unmet needs in material properties is the right combination to improve our customers’ products.”

In this latest investment round, Evonik was joined by private equity firm Chartered Group and TAU Ventures, the venture capital fund of Tel-Aviv University which previously contributed to Castor’s $400 thousand Techstars accelerator fund.

For all of the latest 3D software and investment news subscribe to our newsletter, you can also follow us on Twitter for to-the-minute updates.

Seeking a career change? Search 3D Printing Jobs now.

Featured image shows the Castor Technologies team. Photo via Evonik