German specialty chemicals company Evonik has entered into a cooperative agreement with Cubicure to make materials for its Hot Lithography technology. A patented method of 3D printing, Cubicure Hot Lithography processes materials with higher impact strength, toughness and heat deflection than those typically used in standard “cold” SLA processes. Together the partners have been developing custom formulations for the method to better meet the needs of industrial manufacturing clients. They expect the first products of this partnership to be made available in the near future, and have announced a preview of their findings at November’s Formnext 2019.

“The joint strategic development project with Evonik is already in an advanced state,” comments Robert Gmeiner, CEO and co-founder of Cubicure, adding that this latest advance “is an important building block on our way to stable and scalable additive production processes.”

What is Hot Lithography?

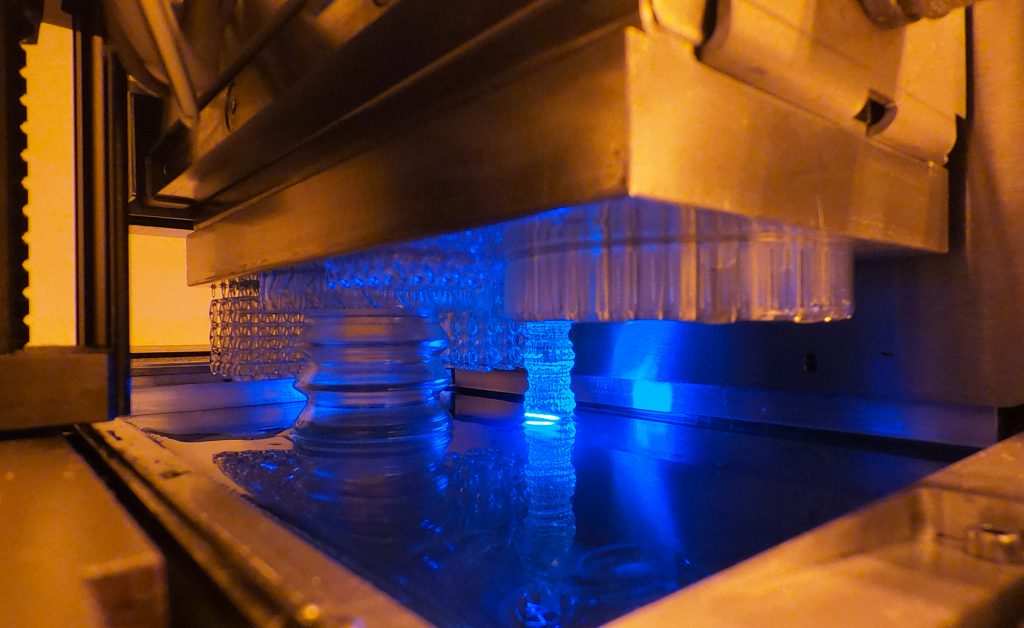

Cubicure was founded in 2015 as a spin-off of TU Wien (Vienna University of Technology). It’s Hot Lithography process was discovered in an attempt to expand the material choices available to common SLA 3D printing. Specifically, the team developed a method that would facilitate the use of high viscosity polymers, thereby enhancing the material properties of the thinner materials used in SLA. As the name of the method suggests, Cubicure achieves this by increasing the operating temperature of its lithography systems. Depending on the material selected, this can be anything up to a temperature of 120°C.

A heated plate carries thin layers of material into the processing area where it is then selectively cured by a precision laser-scanning-system. With this set-up, Cubicure ensures that the temperature of the material remains constant, therefore removing the typical challenges of working with viscous materials.

3D printing at Evonik

As a leading specialty polymer business, Evonik is investing heavily in the future of 3D printing. Recently, the company has taken steps to maximize its output of VESTOSINT 3D printable PA12 to meet demand, and it has been partnering with 3D printing technology developers to be the first to add its materials to their platforms. As Thomas Große-Puppendahl, Head of Innovation Growth at Evonik explains, “Our strategic focus is on developing and manufacturing ‘ready-to-use’ high-performance materials for all relevant 3D printing technologies. Close cooperation with our customers and partners is a prerequisite for advancing innovations.” Earlier in 2019, the company similarly partnered with Evolve Additive Solutions to develop materials for the Selective Thermoplastic Electrophotographic Process (STEP). In SLS, Evonik also acquired Austin based start-up Structured Polymers Inc. in January this year.

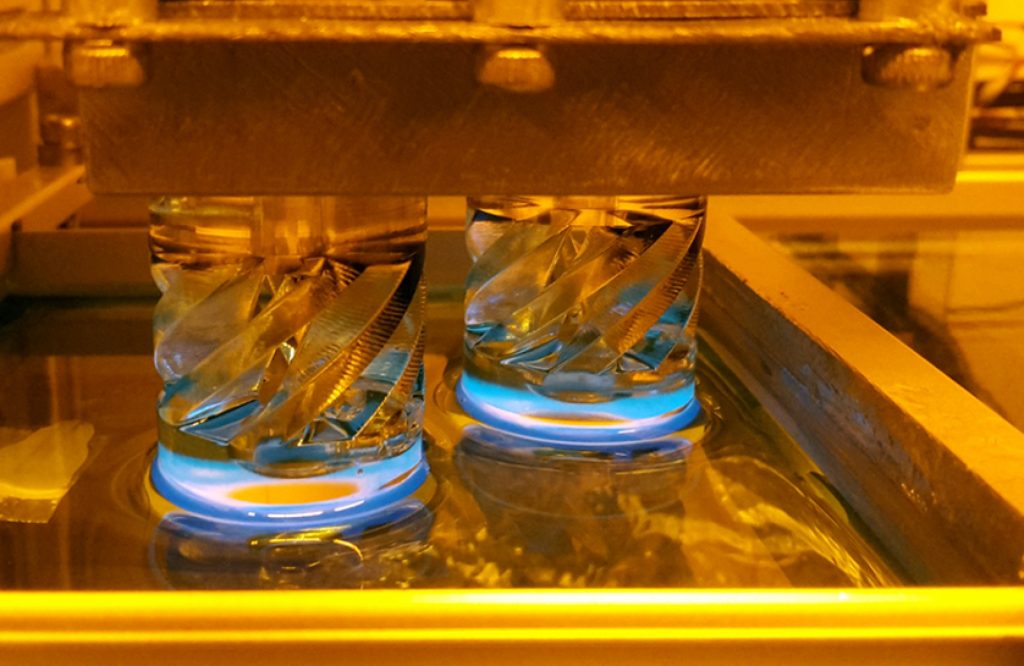

According to Professor Stefan Buchholz, Executive Director of Evonik Creavis GmbH, Evonik has reportedly been using the Cubicure Hot Lithography system to develop “radiation-curing resin systems for a while.” This has included, Professor Buchholz adds, the creation of custom-made “oligomers, specialty monomers and suitable additives.” The first result of this collaboration to be shared with the public is the development of flexible polymers for Hot Lithography.

The flexible Hot Lithography polymers from Evonik are a type of one-component resin system referred to as 1K. With 1K systems, there is no pre-mixing required in the print preparation stages, so they can be applied directly to the printing process, and won’t diminish quickly over time. The elastomer-like properties achieved by these polymers facilitate applications such as 3D printed sealing, grommets, bellows, shock absorbers, protective covers and shoe soles.

At Formnext 2019, Evonik and Cubicure are expected to share more information about the formulation of this resin. From November 19 through the 22, Evonik will be exhibiting in hall 12.1, stand C71 and Cubicure will be in hall 11.1, stand D.48.

For 3D Printing Industry’s coverage of Formnext 2019 and further project updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the high viscosity of resins made 3D printable by Hot Lithography. Photo via Cubicure