German businesses assonic Dorstener Siebtechnik GmbH, Solukon Maschinenbau GmbH and ULT AG are to form a network to develop efficient practice for powder handling in 3D printing. Termed the AM Powder Plus (AMP+) network, it will focus specifically on finding better solutions for powder handling and automated production when using SLM.

The network will be formally introduced to the 3D printing industry at Formnext next month, which will run from the 19 to the 22 November 2019.

Process chain challenges in 3D printing

Powder bed fusion (PBF), and particularly the SLM process, continues to find valuable, cross-sector applications. Machines and the software to support them continue to improve, and companies keep developing new materials, to keep expanding the technology’s potential. In a fourth element connecting each of these factors, developments are also being made to the SLM process chain to make production more efficient, and easier to integrate into existing manufacturing environments. On the one hand, OEMs themselves are coming up with solutions to help customers achieve the most with their machines, as for example in the NextGenAM project from EOS partnered with customers Daimler and Premium AEROTEC. On the other hand, a handful of shrewd startups have taken the opportunity to offer businesses integral pieces of the process that have been missing up until now.

If 3D printing is to continue to grow its adoption within the wider manufacturing sector, more process chain solutions will be needed to help businesses not only integrate the technology within their workflow, but also to make its selection make economical sense.

A circular powder handling process for AM

The AMP+ network is formed of three German engineering companies each with expertise relating to the powder management process chain. In Radevormwald, Western Germany, assonic Dorstener Siebtechnik is a sifting equipment specialist. In Löbau, eastern Germany, ULT AG is a well established business in extraction and filtration. And in Bavaria, southeastern Germany, Solukon Maschinenbau makes peripheral post-processing equipment for additive manufacturing systems. Solukon products in particular tackle depowdering for metal components (launched in partnership with Siemens), as well as unpacking or polymer parts.

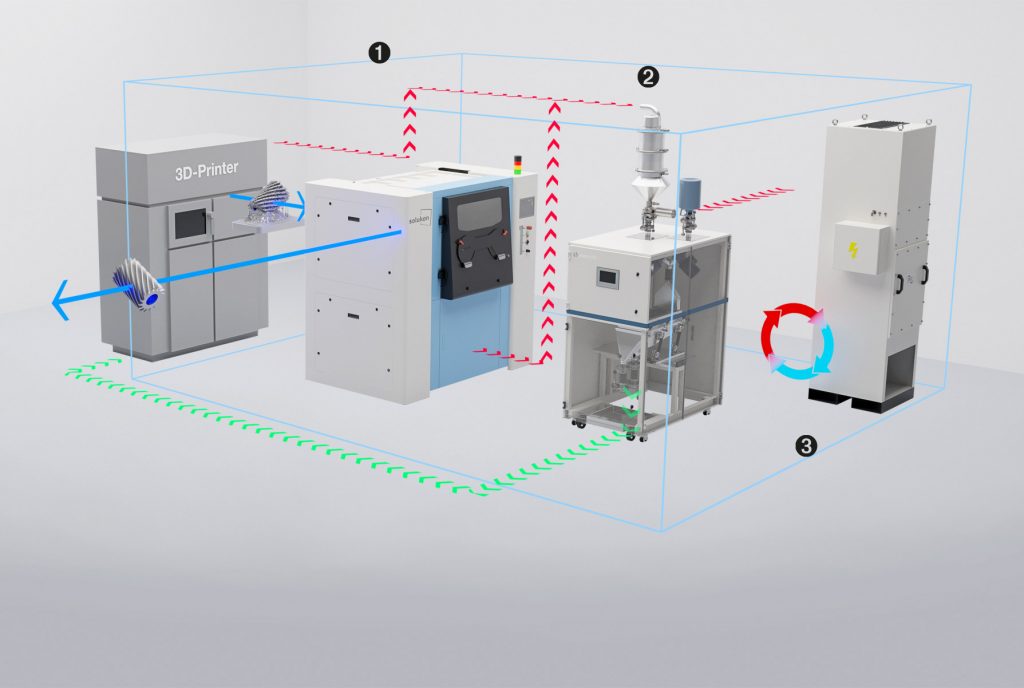

Combining each of the process solutions developed by founding companies, AMP+ will develop a circular powder handling process. This will include the collection, sifting, reprocessing and drying of surplus powder in the metal PBF process; automated component removal and depowdering; recycling of surplus powder; and maintenance of a clean, safe working environment.

Further information on the AMP+ process will be made available at Fromnext 2019 in hall 12.0 at stand C119.

For 3D Printing Industry’s coverage of Formnext 2019 and further project updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a sample AMP+automated process chain for powder handling. Image via AMP+