Continuous Composites, an additive manufacturing materials company based in Idaho, has announced a partnership with French advanced materials company Arkema to combine their respective technologies. The two firms will integrate Continuous Composite’s patented Continuous Fiber 3D (CF3D) printing technology with Arkema’s photocurable resin solutions. The objective of the partnership aims to push the development of additive manufacturing forward using composite material technology.

“As an industry leader in materials, our strategic partnership with Arkema opens the door for us to merge CF3D with their cutting-edge UV curable materials and apply Arkema’s long history in the composites field,” commented Tyler Alvarado, CEO of Continuous Composites.

“This partnership will expedite the development and deployment of CF3D across a broad spectrum of industries and applications.”

Continuous Fiber 3D printing technology

Founded in 2013, and headquartered in Coeur d’Alene, Continuous Composites claims to own “the world’s earliest granted patents on printing with continuous fibers” with its CF3D technology.

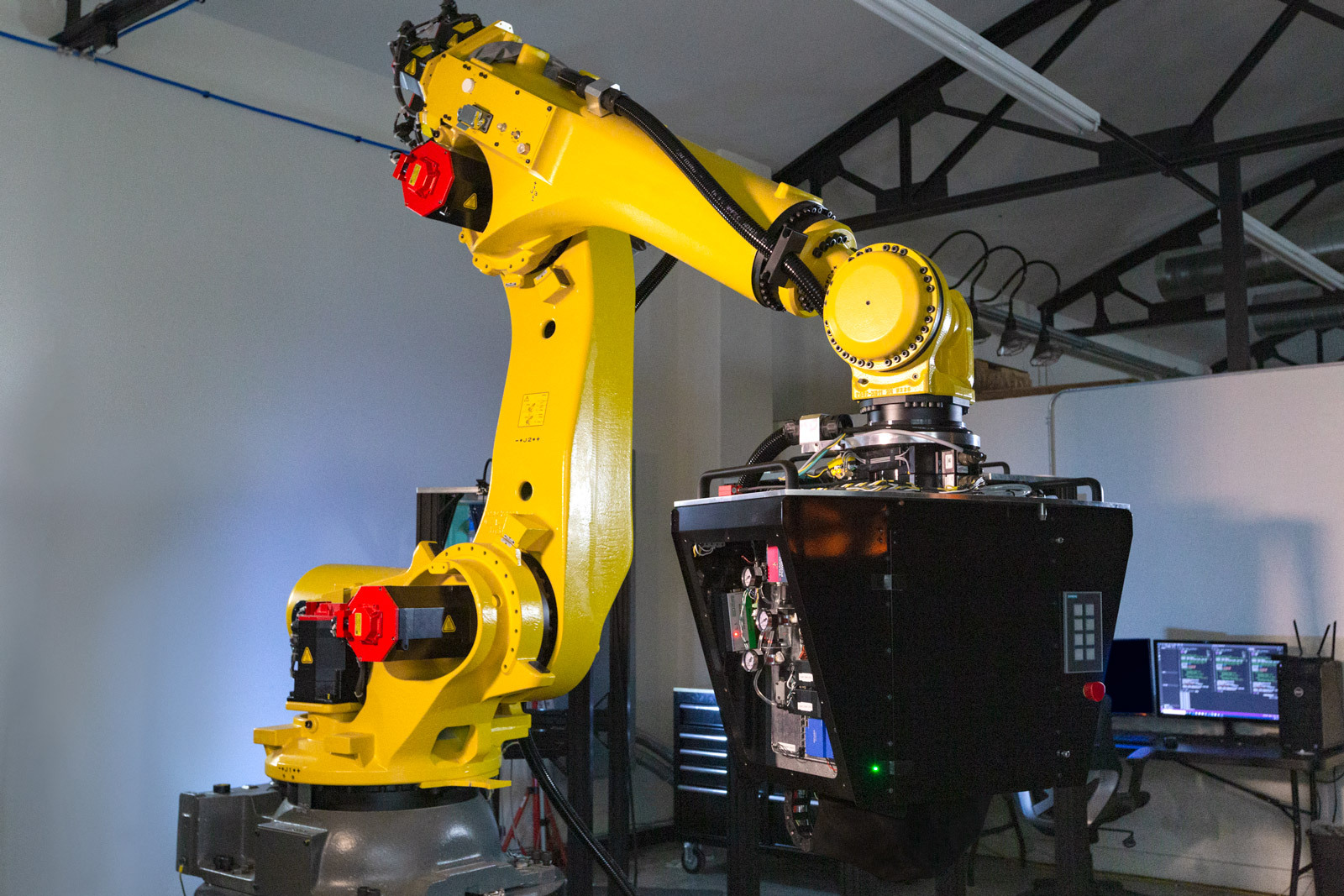

The company’s patented CF3D 3D printing process involves the instant curing of continuous fibers using a thermosetting resin deposited by an end effector (tools or devices at the end of a robot arm). The end effector is driven by Continuous Composite’s proprietary toolpath generation software. This eliminates the need for molds, ovens, and autoclaves, with the purpose of enabling a high material yield.

Aiming to bring composites to new industries, CF3D technology is intended to be scalable, while reportedly reducing the cost of manufacturing with composite materials. The company also claims that it decreases lead times, reduces manual labor, removes the need for expensive equipment, and enables the 3D printing of complex geometries with composite materials.

Combining continuous fiber materials with Sartomer advanced 3D printing resins

The new partnership is being carried out through Arkema’s subsidiary, Sartomer, which specializes in developing advanced 3D printing materials. Its photocurable resins include N3XTDIMENSION and SAR-GEL, which is used to detect water at the bottom of fuel tanks.

Leveraging the capabilities of Arkema’s resins and laboratory testing facilities, Continuous Composites aims to develop, certify and commercialize a library of advanced, lightweight materials for continuous fiber 3D printing. “With Continuous Composites strong technical team and IP, this strategic partnership allows us to develop and position our materials with this revolutionary technology,” explained Sumeet Jain, Global Business Director for 3D Printing at Sartomer.

“We are excited to leverage our materials expertise in developing CF3D, disrupting traditional composites manufacturing, and bringing these advanced composite materials to new industries.”

Other companies developing continuous fiber 3D printing technology includes Anisoprint, a Russian manufacturer of continuous fiber 3D printers and materials. The company’s 3D printing technology processes composite materials to produce structural parts with the strength and properties required for end-use applications.

California-based Arris Composites is also developing continuous carbon fiber composites, and is targeting the aerospace, automotive, and consumer product sectors. The company recently emerged from stealth mode for the past two years with the announcement of a $10 million funding round.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the patented CF3D process uses a robot arm. Photo via Continuous Composites.