Massachusetts-based industrial 3D printer manufacturer Desktop Metal and German chemicals company Evonik have announced a partnership on photopolymer and materials development.

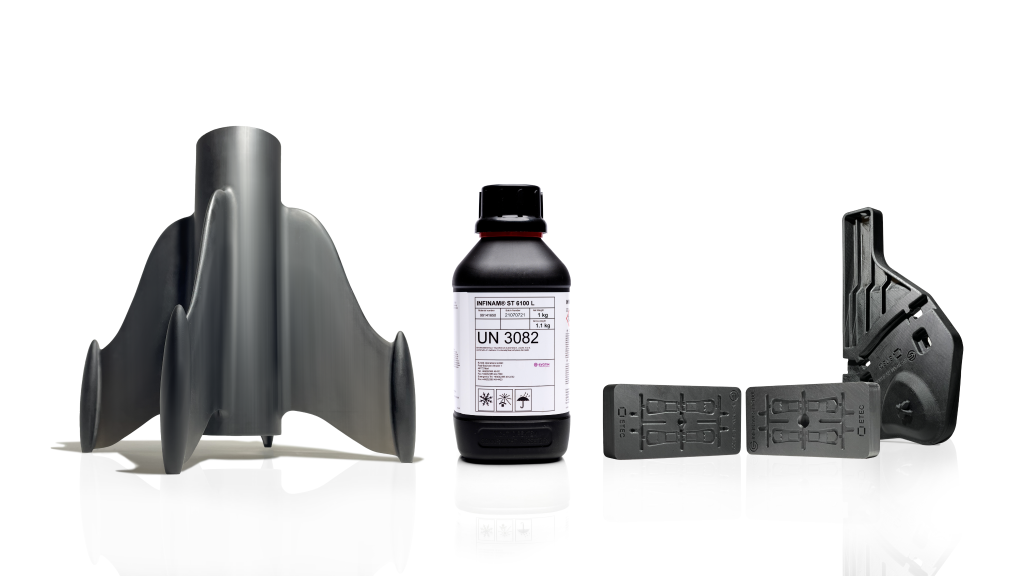

This partnership aims to qualify Evonik’s INFINAM ST 6100 L material on Desktop Metal’s ETEC Xtreme 8K and Pro XL printers. INFINAM ST 6100 L offers properties ideal for 3D printing molds, models, tooling, and end-use parts in aerospace, automotive, and electronics. When paired with the ETEC Pro XL’s 65 μm resolution, parts printed in INFINAM ST 6100 can accurately achieve intricate details and fine geometries. Additionally, parts created with this material can seamlessly undergo machining, polishing, and other post-processing processes.

“Collaboration with customers and partners is an important driver of innovation for us,” said Vitor Lavini, head of Evonik’s photopolymer market segment in the company’s Additive Manufacturing Innovation Growth Field. “The validation of ST 6100 L on Desktop Metal’s printers – especially the ETEC Xtreme 8K – fits with Evonik’s vision that larger and faster DLP printers will increase productivity, substantially reduce costs per part, and enable series production in the long run.”

A combination of speed and strength for industrial 3D printing

As stated by the company, Evonik’s INFINAM ST 6100 L offers an ultimate tensile strength (UTS) of 90 MPa, flexural stress of 135 MPa, and a heat deflection temperature (HDT) of 120°C. It also boasts exceptional precision, surface finish, and resilience to various chemicals and ultraviolet (UV) degradation. Desktop Metal’s ETEC brand for polymer 3D printing leads in Digital Light Processing (DLP) hardware and offers a meticulously curated portfolio of the finest AM materials available worldwide, says the company.

As an industrial-grade DLP printer for high-volume production, the ETEC Xtreme 8K has a significant 66-liter build volume and two overhead projectors. With dimensions of 450 × 371 x 399 mm (17.72 x 14.61 x 15.71 in), the ETEC Xtreme 8K offers an expansive build volume. It is worth noting that this system is manufactured at Desktop Metal’s Polymer Center of Excellence located in Richardson, Texas.

With a price tag under $40,000, the ETEC Pro XL is positioned as a premium DLP printer, says Desktop Metal. It features 385 nm wavelength technology, 5mW/cm2 power, and Hyperprint closed-loop printing, all contributing to superior results achieved at high printing speeds. Offering a build volume of 249.1 x 140.1 x 165.1 mm (9.8 x 5.5 x 6.5 in), the ETEC Pro XL is designed to meet diverse additive manufacturing needs.

Components produced using Evonik’s INFINAM ST 6100 L material on the ETEC Xtreme 8K will be showcased at the Additive Manufacturing Users Group (AMUG) 2024 Conference in Chicago, from March 10 to 14, at the Evonik booth P12, Salon D.

Material development alliances

The collaboration between Desktop Metal and Evonik’s is the latest in a long list of material development efforts. Last month, Quantica partnered with ImageXpert, integrating NoveJet JetPack with JetXpert for material jetting testing. This collaboration aims to democratize NovoJet printhead technology, to advance digital manufacturing and material development. Tailored for ImageXpert’s Dropwatcher, JetPack analyzes droplet characteristics, enabling automated testing.

With half-micron resolution and 8 million fps exposure time, Dropwatcher offers precise measurements. Quantica aims to extend its inkjet printing tech to electronics, covering conductive tracks, insulation layers, solder pastes, and more. Ultimately, the partnership aims to transition traditional analog manufacturing processes into the digital space, promoting material development and inkjet 3D printing capabilities.

Elsewhere, Mechnano and Bomar launched the T50B masterbatch designed for 3D printing. Leveraging Mechnano’s D’Func technology, T50B focuses on enhancing mechanical properties and maintaining consistent electrical performance in AM resins. With elevated CNT concentration and minimal viscosity, it easily incorporates into resin formulations, compatible with various resin types and printing technologies. T50B allows fine-tuning of electric resistivity and improves mechanical characteristics, promising enhanced component performance.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed parts printed on ETEC hardware from Desktop Metal using Evonik INFINAM® ST 6100 L. Image via Evonik.