German specialty chemicals company Evonik has launched its first software tool for 3D printing. The application is designed to assist manufacturers in selecting the appropriate additive manufacturing process for their desired part, depending on geometry, material and financial analysis of the design, saving costs in the process.

The software was developed by Castor, an Israeli start-up that Evonik’s Venture Capital division invested in late 2019. “With the software,” comments Thomas Große-Puppendahl, head of the innovation growth field additive manufacturing at Evonik, “broader adoption of 3D printing at a commercial scale is now possible,”.

“That will offer us better insights into customer needs and preferences in order to develop new “ready-to-use” materials.”

Realizing the potential of 3D printing with Castor software

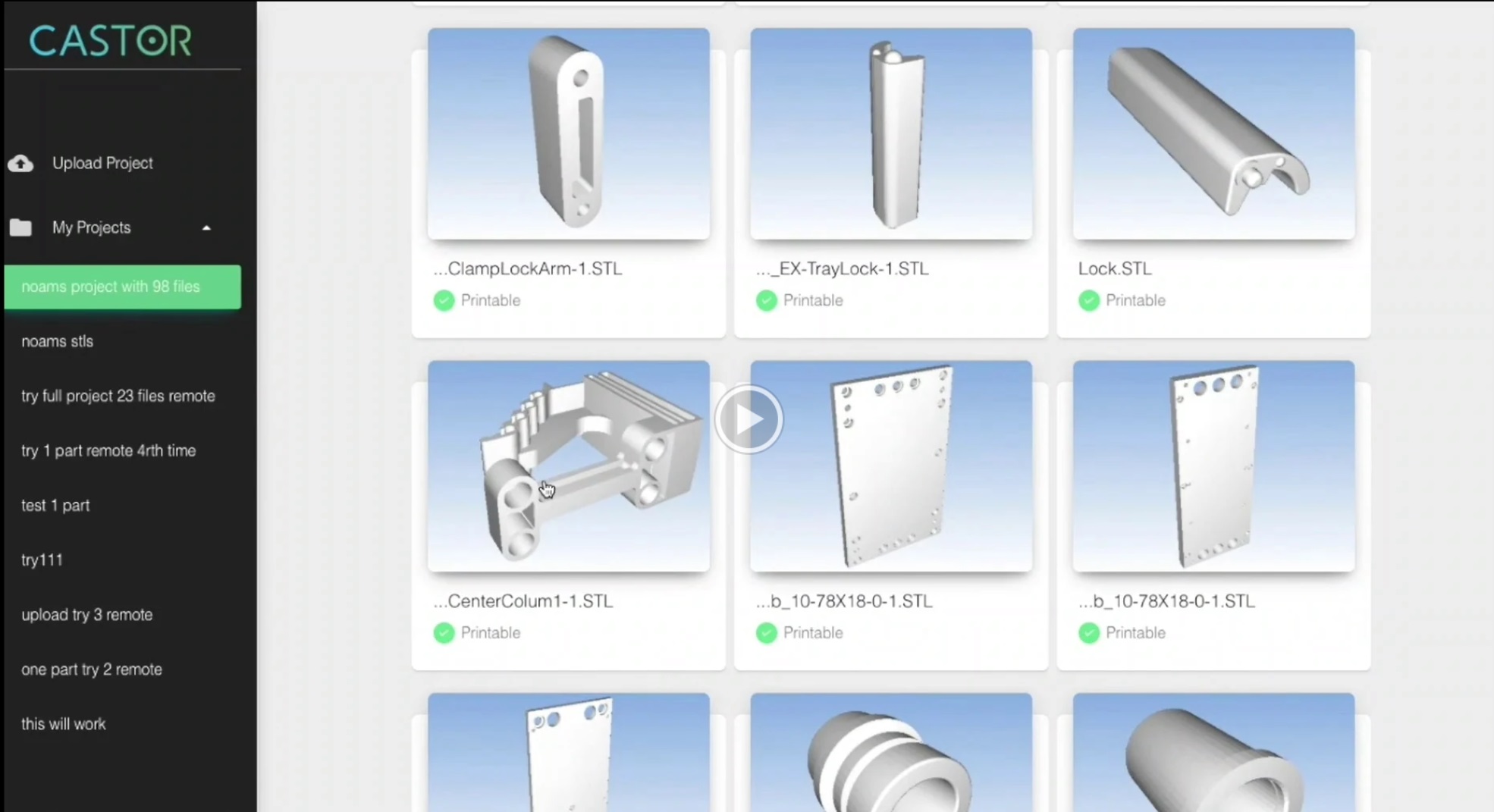

A software developer, Castor is responsible for creating a platform enabling customers to assess part printability, select the best material for a specific purpose, and attain cost and lead time estimates through CAD file analysis. The software can help users locate the break-even point for additive manufacturing against traditional production methods. Enabling engineers to identify cost reductions and time savings, the platform facilitates the adoption of 3D printing, as well as carving out a place for the technology within the wider manufacturing ecosystem.

When Evonik announced that it had invested in Castor. Part of the investment included the combination of the company’s material expertise with Castor’s platform, resulting in Evonik’s new software tool that the company claims is “accessible for all industries.”

The tool will allow customers to identify parts that could be printed with materials such as high-performance polymer powders and filaments. It will also suggest the use of Evonik’s additives that can modify material properties, for example, improving the flowability or making the finished part more robust.

“The release of Evonik’s new software which is powered by Castor’s technology is a key step in expanding our product portfolio. We are thrilled about the opportunity to solidify the relationship with Evonik and look forward to materializing our vision to increase the amount of end-use parts manufacturers using additive manufacturing,” said Omer Blaier, CEO of Castor.

Evonik in the 3D printing industry

With the launch of its first software for 3D printing, Evonik continues to build its portfolio of additive manufacturing technology. It stepped up its presence in the industry in February 2018 when the company announced its intentions to increase the production of its VESTOSINT range of 3D printing powders by 50%. Nearing completion in February of the following year the company reported that the expanded site was worth around €400 million. In May 2019, it then closed a plant in Witten to focus more on the VESTOSINT site’s construction.

Evonik has also been developing its materials for various applications in the medical sector. In November 2019, the company signed a long-term agreement with 3D printed scaffold developer BellaSeno GmbH to develop 3D printed breast scaffolds using its RESOMER line of materials. Earlier in February, Evonik also announced that it had developed a Selective Laser Sintering (SLS) bioresorbable powder designed to create 3D printed implantable medical devices.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Castor’s 3D printing analysis software. Image via Castor Technologies.