Leading German specialty chemicals business Evonik has signed a long-term agreement with 3D printed scaffold developer BellaSeno GmbH. The agreement guarantees BellaSeno’s use of Evonik’s bioresorbable polymer RESOMER in the production of its proprietary 3D printed Senella product.

BellaSeno achieved ISO 13485 certification for its Senella breast scaffolds in July this year, and successfully raised a further €1 million to continue development of the product. With Senella, the company aims to improve procedures for breast reconstruction, augmentation and revision surgery, creating implants that can safely be absorbed by the body.

“Senella breast implant scaffolds can potentially enhance the quality of life of millions of patients worldwide who undertake surgical procedures each year,” comments Dr. Jean-Luc Herbeaux, SVP and General Manager of the Health Care business line at Evonik.

“This agreement underlines the ability of Evonik to leverage the safety and versatility of RESOMER polymers, together with our advanced application technology services, to support customers in the commercialization of innovative medical devices.”

3D printed breast implants

BellaSeno was founded in 2015 to develop an alternative to silicone breast implants. These implants, used for reconstruction, augmentation and revision of breast tissue, permanently introduce foreign material into the body of a patient. As such, they can cause complications, or, at a later stage, they must be replaced putting the patient at further risk.

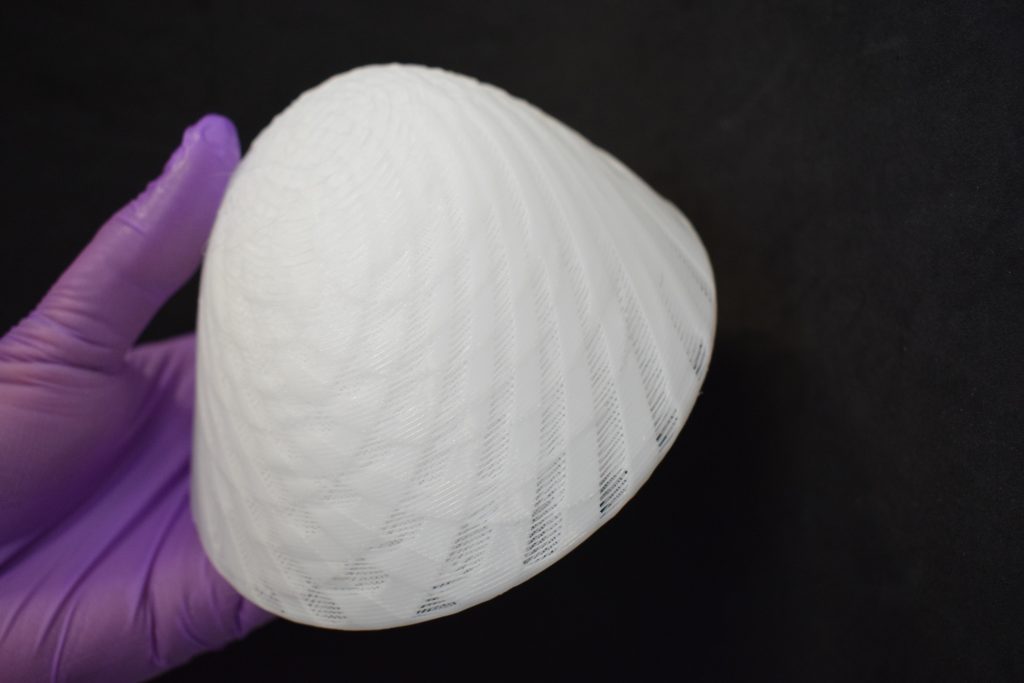

In place of silicone, BellaSeno has proposed the use of a polycaprolactone (PCL) tissue scaffold, that can be used to encourage the growth of natural tissue, while gradually being absorbed by the body. For this, the company uses Evonik RESOMER polymers – a family of materials formulated for efficacy, biocompatibility, and safety.

The Senella range of bioresorbable scaffolds from BellaSeno are 3D printed and come in various different sizes to meet the needs of a patient. 3D printing enables the company to develop an array of complex 3D Cell Culture Meshes and Custom Scaffolds which can also be used for research purposes.

Senella availability

ISO 13485 certification clears Senella implants for use in the pre-clinical stage of development. As yet, the range does not have CE-marking or FDA-approval, making them unavailable for human use. However, the first-in-human clinical trials of the scaffolds with are scheduled to commence in Germany in the latter quarter of 2019.

Evonik’s Dr. Herbeaux comments, “Evonik is pleased to be partnering with BellaSeno in the clinical development and commercialization of their innovative, 3D printed breast implant technology.” Dr. Simon Champ, Co-Founder and Chief Executive Officer of BellaSeno, adds, “BellaSeno GmbH is very excited to be working together with Evonik in this collaboration. The level of support provided by Evonik has been excellent.”

Looking to hire additive manufacturing experts? Register as an employer on 3D Printing Jobs now. For more of the latest medical 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image shows a BellaSeno 3D printed bioresorbable Senella breast scaffold. Photo via BellaSeno