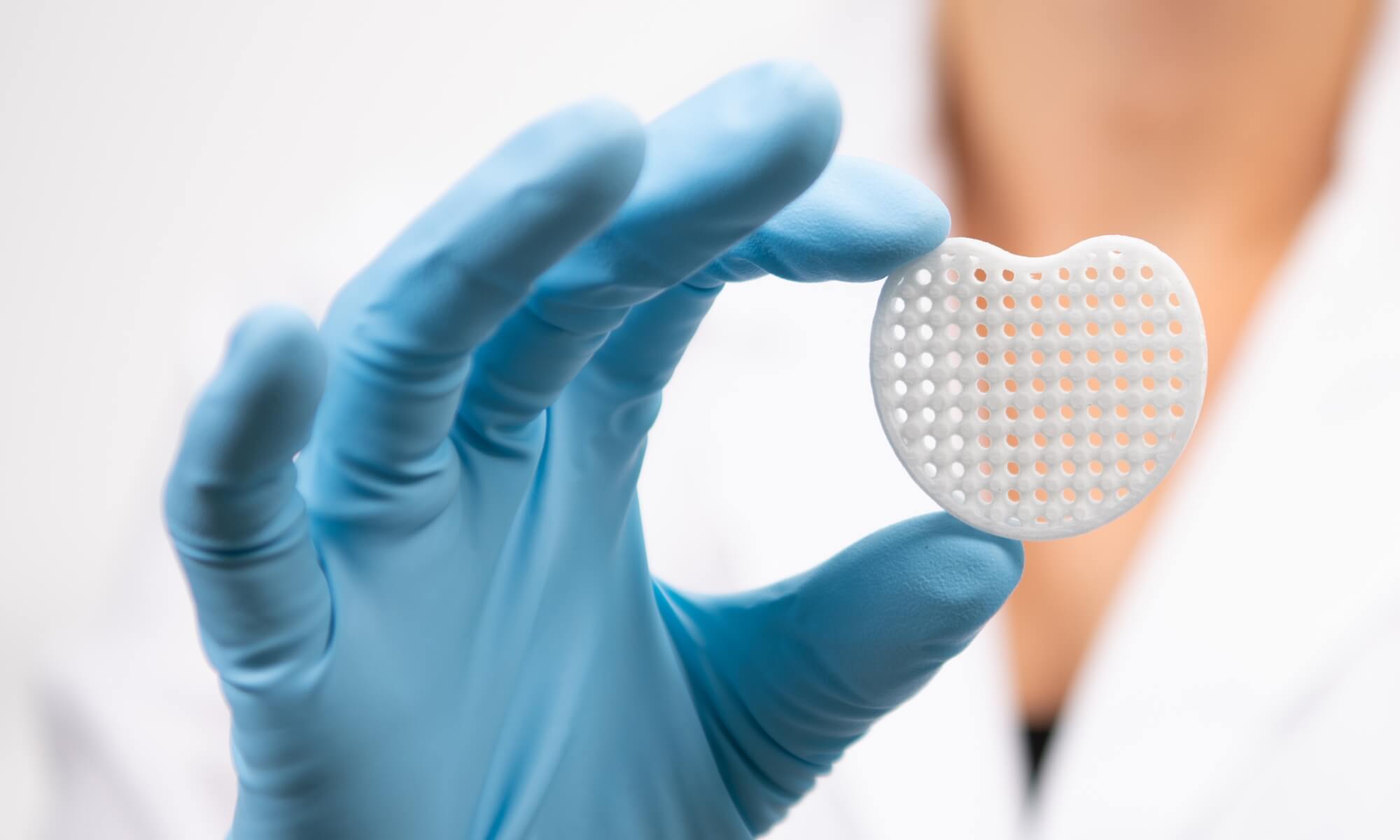

German industrial chemical corporation Evonik has developed a Selective Laser Sintering (SLS) bioresorbable powder designed to create 3D printed implantable medical devices.

Known as RESOMER PrintPowder, this material has been created to produce strong, durable parts with stress shielding capabilities to prevent bone loss as a result of an implant. Dr. Jean-Luc Herbeaux, SVP and General Manager of the Health Care business line, stated:

“The free-flowing processability of RESOMER PrintPowder will, for the first time, allow medical device companies to utilize SLS 3D printing technologies to create complex bioresorbable implants with precisely tailored mechanical properties.”

“With the launch of RESOMER PrintPowder, Evonik becomes the first commercial GMP supplier of bioresorbable polymers with a complete portfolio of powders, filaments, and granules suitable for use with all core 3D printing technologies.”

RESOMER PrintPowder

Under the Nutrition & Care segment of Evonik, the Health Care business line, serves over 1000 pharmaceutical, nutraceutical, and medical device customers. Within this sector is the RESOMER portfolio of bioresorbable polymers which features semi-crystalline and amorphous polymers. Previously, Evonik released RESOMER Filaments, a series of bioresorbable materials for FFF/FDM.

As the latest addition to the RESOMER line, PrintPowder can be used to fabricate 3D printed Craniomaxillofacial (CMF) plates, spinal fusion cages, scaffolds for soft tissue repair and dental meshes. According to Evonik, this material can improve patient healing and device performance across orthopedic, dental and soft tissue application areas.

Evonik and 3D printed medical devices

In November 2019, Evonik signed a long-term agreement with 3D printed scaffold developer BellaSeno GmbH to develop 3D printed breast scaffolds using RESOMER materials. Prior to this, the company led a “high single-digit million-euro” round of funding for Meditool, a medical device start-up in Shanghai, the company’s first direct investment in China.

Evonik also entered into a cooperative agreement with Cubicure to make materials for its Hot Lithography technology. This patented method of 3D printing, known as Cubicure Hot Lithography, processes materials with higher impact strength, toughness and heat deflection than those typically used in standard “cold” SLA processes.

Nominations for the 2020 3D Printing Industry Awards are now open. Vote now to have your say.

Keep up to date with industry-relevant financial reports this season by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a 3D printed structure created with RESOMER PrintPowder. Photo via Evonik.