Additive Flow, a UK-based optimization software developer, has formally introduced its AM optimization software FormFlow.

Established in 2017, the company aims to solve many of the digital challenges currently present within the additive manufacturing workflow with its multi-functional, physics-driven software.

FormFlow is designed to be adaptable to a range of materials and processes, facilitating efficient and sustainable design for a wide variety of applications.

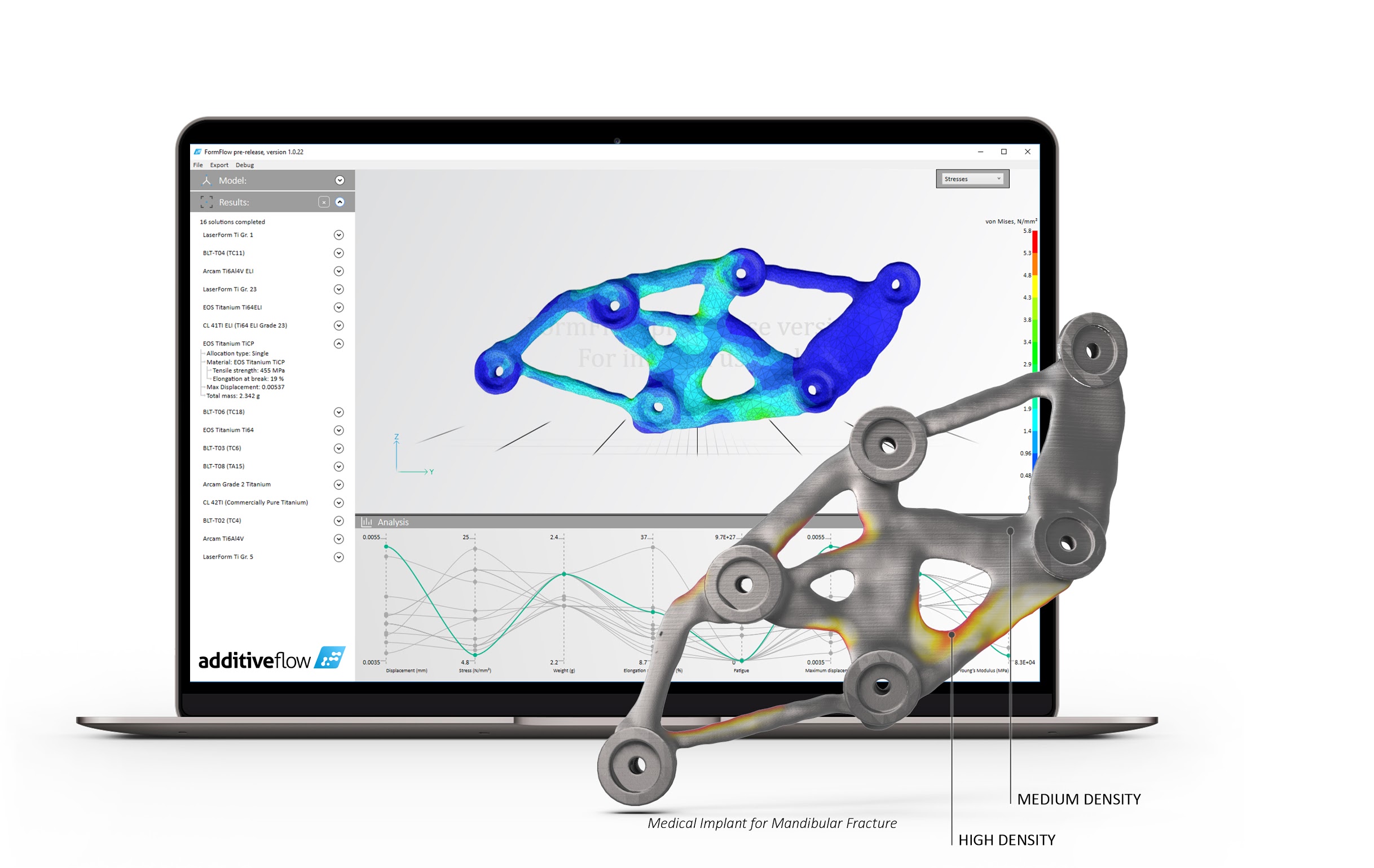

FormFlow optimization software

Designers and engineers can face numerous design challenges present in the additive manufacturing industry. On a large production scale, it is imperative that additive manufacturing processes for product development and production applications are optimized to save time and money.

FormFlow is a multi-functional program with the ability to apply multiple user-defined parameters for simultaneous geometry, process parameter, and material optimization. The software uses physics-driven algorithms to process and solve complex performance issues in the design phase. FormFlow delivers optimally performing parts cost-effectively, sustainably and in minimal time.

The software is also designed to be AM process indiscriminate, so it can be tailored to work with different material properties and even multi-material designs. By optimizing part geometry, placement and even material choice, the software allows users to view the productivity, cost and performance outcomes of different designs.

The Additive Flow team and designing for additive manufacturing

The London start-up is comprised of strong advocates for industrial 3D printing, with the vision of seeing the technology widely adopted globally. One of the barriers to adoption is at the digital design phase, which includes design for additive manufacturing, multiple parameter design optimization, process simulation, process parameter optimization, material selection, and part placement. Additive Flow intends to provide a comprehensive digital solution to the entire digital workflow.

The company is currently operating on a project-by-project consultancy basis with a multitude of companies from OEMs to SMEs. Its versatile software is adaptable to specific bottlenecks in the workflows of a range of applications. Additive Flow plans to release its FormFlow software on license later in 2020.

Additive Flow is not the only company in the AM optimization software market. Veteran 3D printing company Materialise recently released the latest iteration of its Magics software to increase productivity and efficiency in metal additive manufacturing. The company is focused on facilitating the adoption of the Design for Additive Manufacturing mindset to allow designers and engineers to fully realize AM’s production capabilities.

Elsewhere, in New York, LINK3D has launched the Production Planning System powered by advanced build simulation and machine connectivity. These companies all realize the importance of solving the initial challenges in the design phase of AM production as lifting this barrier will see AM more widely accepted for industrial applications.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Additive Flow’s FormFlow software. Image via Additive Flow.