The month of March 2020 saw the publication of additive manufacturing safety standards, new 3D printing materials qualified, innovative biomaterial discoveries, and even plans to 3D print explosives.

Read on for the standout developments of March 2020, which involved the likes of ASTM International, ExOne, Wohlers Associates, Siemens, Stratasys, Relativity Space, and the UK Defense Agency.

3D printing vascular structures

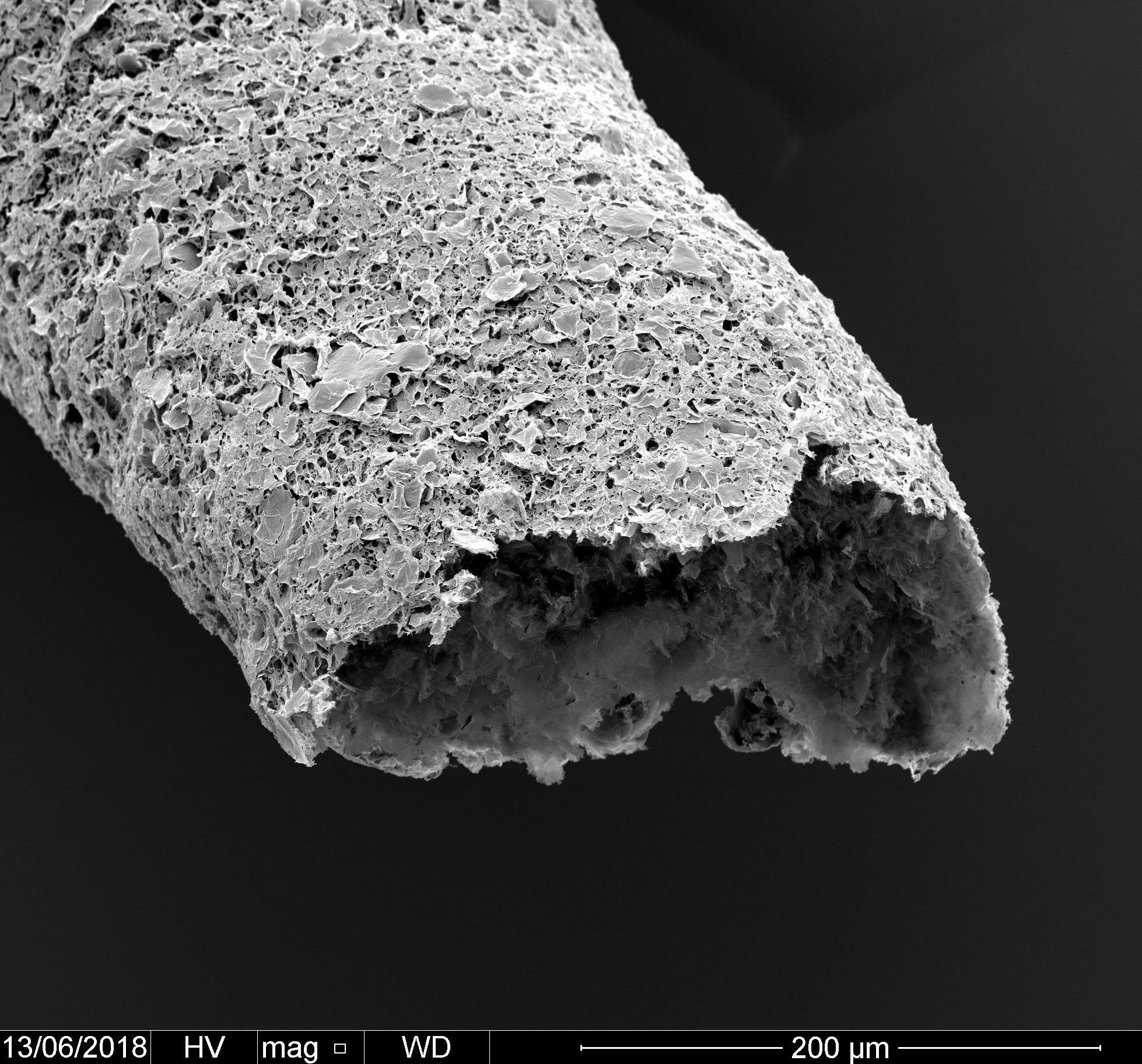

The beginning of the month saw a new study published, exploring the possibility of 3D printing graphene oxide with a protein to form tubular structures that replicate vascular tissues. Led by Professor Alvaro Mata at the University of Nottingham and Queen Mary University of London, the researchers precisely mixed the two components to form a biomaterial that could then be used as a bio-ink to 3D print intricate structures with fine resolutions.

“This work offers opportunities in biofabrication by enabling simultaneous top-down 3D bioprinting and bottom-up self-assembly of synthetic and biological components in an orderly manner from the nanoscale,” said Mata.

“This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs, meaning treatments could potentially reach patients much more quickly.”

Relativity Space successfully lands new HQ

Meanwhile, rocket building firm Relativity Space secured its new headquarters in the heart of the US’s aerospace community in Long Beach, California. Home to both the firm’s business operations and its automated metal additive production line, the facility will enable Relativity to produce Terran 1, the world’s first fully 3D printed rocket.

More recently, the firm raised $500 million from investors despite having yet to successfully fire the Terran 1 into orbit, although it’s currently slated for a commercial launch in 2021.

Siemens ups investment in Stratasys for 30-year rail project

Elsewhere, Siemens Mobility Services invested in two new industrial-grade Stratasys Fortus 450mc 3D printers to support spare part production for 13 additional high-speed Velaro trains Siemens is building for Russian train firm RZD.

The new trains will be added to an existing fleet of 16, with a 30-year agreement to maintain and service the trains also part of the deal. The two Stratasys machines were installed in St. Petersburg and Moscow to enable Siemens’ team to rapidly 3D print rail replacement components on-demand, as part of Siemen’s “Easy Sparovation Part” network in Russia.

Reversible 4D printing

4D printing, by incorporating the next dimension, is naturally the next step up from 3D printing and involves the shape of a 3D printed object changing over time. In March, researchers from Singapore University of Technology and Design (SUTD) and Nanyang Technological University (NTU) presented a method in which this process can be reversed – i.e, the object changes back to its original 3D printed shape – without the need for hydrogel or human input.

“While reversible 4D printing in itself is a great advancement, being able to use a more robust material while ensuring a more precise reversal during shape change is revolutionary as it allows us to produce complex structures that cannot easily be achieved through conventional fabrication,” explained Professor Chua Chee Kai, lead researcher and Head of Engineering Product Development at SUTD.

“By relying on environmental conditions instead of electricity, it makes it a game-changer across various industries, completely changing the way we design, create, package, and ship products.”

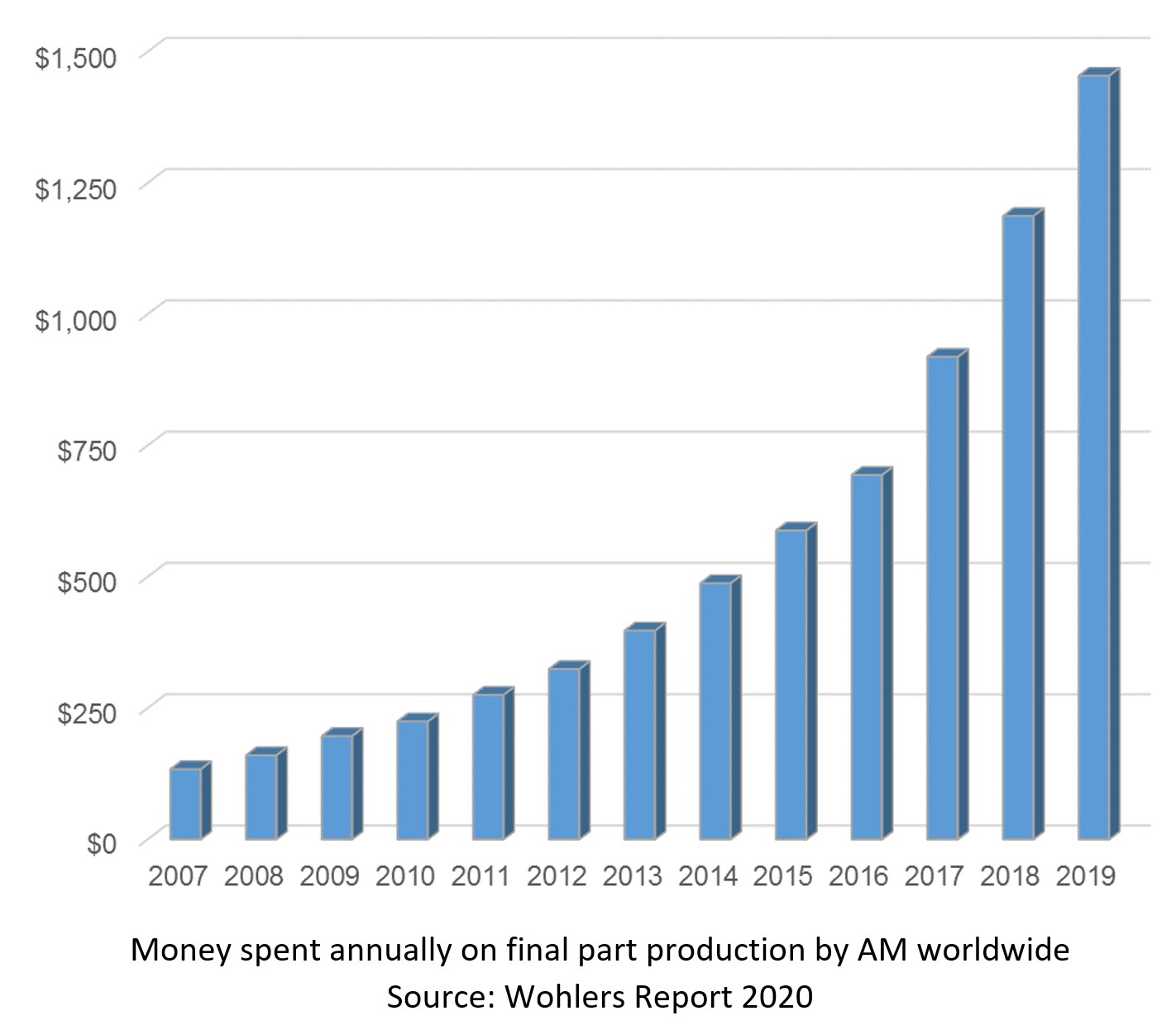

Wohlers Associates publishes annual State of 3D Printing report

In mid-March, Wohlers Associates, the Colorado-based additive manufacturing consultancy firm of Terry Wholers, published the 25th consecutive installment of its report on the state of 3D printing. This year, the report detailed information on additive manufacturing industry growth, particularly regarding maturing and emerging applications of 3D printing for series production.

The report also included a review of additive manufacturing in the dental industry, discussed 77 early-stage investments valued at $1.1 billion, and listed 72 industry partnerships from the past 12 months.

DSTL’s explosive plans

The Defense Science and Technology Laboratory (DSTL), an executive agency sponsored by the UK’s Ministry of Defense (MOD), revealed it had begun developing 3D printed explosives, in a project which sought to create new possibilities for explosive effects and reduce transportation and storage costs. 3D printing is to be used to produce new energetic formulations within the MOD’s Future Energetics Project, which has seen almost £10 million investment since its establishment in 2015.

“Energetics knowledge and experience is vital for the UK to develop the best equipment, platforms, and operational assets,” the DSTL stated.

“We need to know how energetic systems damage or defeat our platforms and how we can counter threats, so we can advise on things like countermeasures, detection, safety, transportation, and disposal, all while working with explosives in accordance with legislation.”

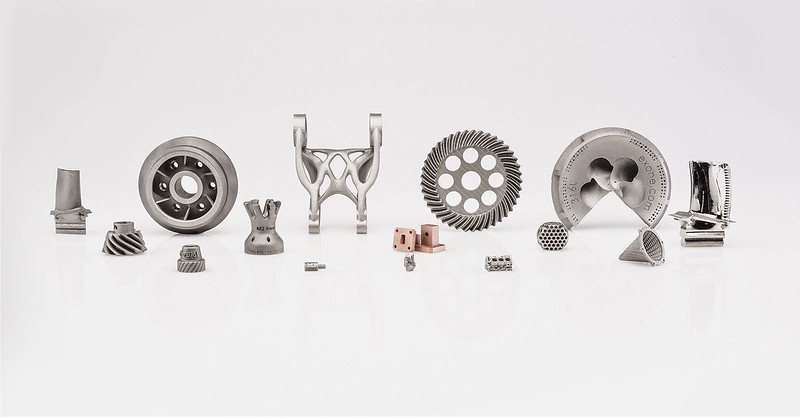

21 new qualified materials from ExOne

Shortly after, leader in industrial sand and metal binder jetting 3D printers, ExOne, announced the qualification of 21 new materials for use in its machines, in addition to its brand new qualification system. The firm’s growing set of qualified materials came as a result of its extensive list of customer collaborations, including partnerships with NASA and Virginia Tech.

As of the announcement, owners of ExOne printers had the option of choosing between 10 single-alloy metals, six ceramics, and five composites, alongside over 24 additional powders qualified for 3D printing. Since then, ExOne has qualified Inconel 718 for use with its metal binder jetting systems and reached an agreement with the ceramics producer ITOCHU Ceratech to validate its Naigai Cerabead materials for use with its sand 3D printers.

AM facility safety standard agreement

Safety consulting and certification firm Underwriters Laboratories (UL) and global standards developer ASTM International signed a memorandum of understanding (MoU) for an ASTM-ISO standard for additive manufacturing facility safety management. The first agreement of its kind between the two bodies, the MoU sought to establish a framework for developing an international, dual-logo ISO and ASTM standard.

“This partnership brings together both organization’s expertise and shared desire to drive global safety,” said Phil Piqueira, Vice President Global Standards at UL. “It leverages ASTM’s technical committee and relationship with ISO with our document and research to drive impact and positively influence the international standards landscape.”

Singapore’s Joint Industry Programme enters Phase 2

Elsewhere, the Maritime and Port Authority of Singapore (MPA), Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC) and Singapore Ship Association (SSA) announced Phase 2 of their Joint Industry Programme (JIP) to integrate 3D printing into the marine sector.

During Phase 2, the organizations will focus on selecting applicants to 3D print the parts identified as suitable for additive manufacturing in Phase 1, and install them onboard vessels. Applicants will then have to produce a comprehensive project report outlining the technical assessment and commercial viability of each component.

JIPs conclude for Adoption of AM in oil and gas sector

Ending March’s news round-up is the conclusion of two Joint Industry Projects (JIPs) which sought to establish guidelines for the production and qualification of 3D printed parts for the oil and gas and maritime industries. Organized by international classification society, DNV GL, and involving 20 different partners, the JIPs aimed to develop guidelines to help qualify parts produced by Laser Powder Bed Fusion (LPBF) and Wire Arc Additive Manufacturing (WAAM) over a two year period.

The first program centered on the creation of a framework to guarantee the components produced using WAAM and LPBF meet quality and safety requirements, while the second project focused on developing a “toolbox” for part selection, supply chain set-up, and economic viability.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows RZD high-speed Sapsan train fleet. Photo via Stratasys.