ExOne, the global leader in industrial sand and metal binder jetting 3D printers, has announced the qualification of 21 new materials for use with its machines alongside its brand new qualification system. John Hartner, ExOne’s CEO, has attributed the growing set of qualified materials to the U.S.-based company’s extensive list of customer collaborations, which includes partnerships with NASA and Virginia Tech.

ExOne’s growing customer collaborations

Earlier in 2019, ExOne announced the intensification of its collaborations to advance binder jetting technology at a faster rate.

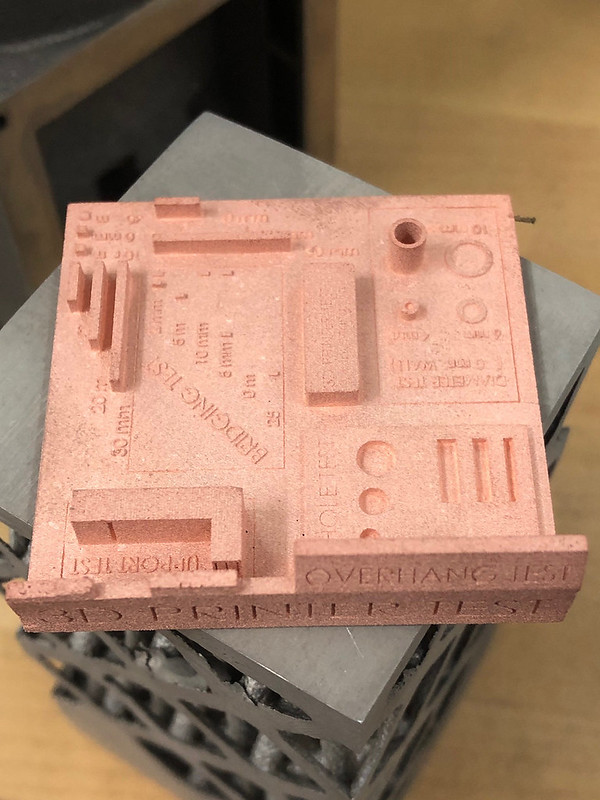

At least nine ExOne customers have played a major role in the qualification of the ExOne materials so far. Included in this list is Virginia Tech, where Professor Chris Williams, Ph.D., has been 3D printing copper on ExOne machines since 2013. He started his work on an ExOne R2 machine, launched in 2003, and recently, an Innovent+ with Triple ACT advanced compaction technology.

Major collaborations include H.C. Starck, who assisted in qualifying tungsten heavy alloy; Global Tungsten & Powders, who assisted with tungsten carbide-cobalt, and SGL Carbon, who had a hand in qualifying Silicon Carbide infiltrated with Silicon. Other notable institutions that have contributed to the customer-qualified list of materials are NASA, Oak Ridge National Laboratory, the U.S. Army, the U.S. Department of Energy, and the University of Texas at El Paso.

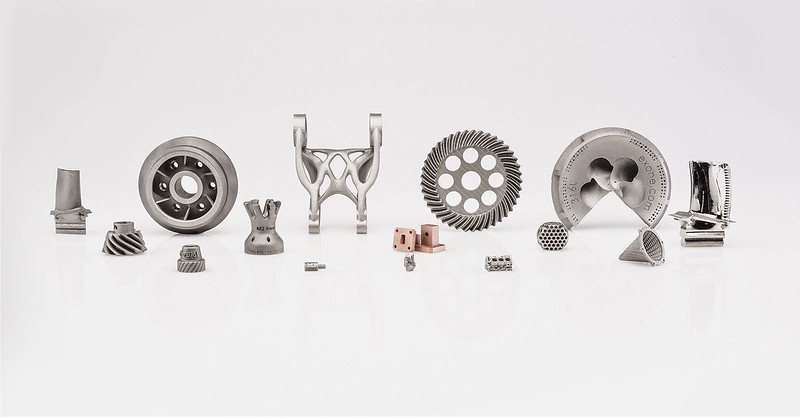

Thanks to these collaborations, owners of ExOne 3D printers now have the option to choose between 10 single-alloy metals, 6 ceramics, and 5 composites alongside more than 24 additional powders that have been qualified for 3D printing based on testing in a controlled R&D environment.

ExOne and binder jetting

ExOne developed the first iteration of their binder jetting technology in 1996, whereby powdered material is transformed into dense and functional precise parts at high speeds. An industrial nozzle deposits minuscule, precise amounts of liquid binder onto thin layers of powder multiple times to build up a 3D shape.

“ExOne continues to make aggressive and outstanding progress in qualifying new materials for 3D printing on our machines,” said John Hartner. “Qualifying a new material for binder jet 3D printing is complex work that involves optimizing how materials, machines, and processes work together. We would like to thank our customers and partners for their assistance in accelerating this important work, which is enabling more sustainable manufacturing and part designs.”

Binder jetting, like many other 3D printing technologies, is considered a sustainable method of metal fabrication due to the lack of waste generated during printing. At the same time, it enables design freedom on lightweight parts that would not otherwise be manufacturable.

ExOne believes the ability to binder jet certain materials, like aluminum, will have major implications for industries such as automotive and aerospace. For that reason, ExOne is working with a number of manufacturing companies to accelerate the qualification of aluminum within its new qualification system and optimize commercial 3D printing of the lightweight metal.

“While our teams can binder jet aluminum in controlled R&D environments today, we believe that optimizing this material for high-speed 3D printing will eventually transform how car and airplane parts are made, making them smarter and lighter weight,” said Rick Lucas, Chief Technology Officer at ExOne. “Based on high demand from the marketplace, we have fast-tracked development of this material for use on our machines.”

ExOne’s new qualification system

The binder jetting company now has a new proprietary qualification system for materials used with its 3D printing systems. The three material qualification levels recognize different degrees of material readiness for industrial applications.

Third-Party Qualified Materials (7) have passed rigorous ExOne tests over multiple builds and have verified material property data from an independent third party. Materials in this category include M2 tool steel and tungsten with bronze.

Customer-Qualified Materials (14) have been qualified by ExOne customers with their own standards and are currently being successfully 3D printed for their own applications. Materials in this category include titanium, Inconel 625 and alumina.

R&D Qualified Materials (26) have passed a preliminary qualification phase by ExOne and are deemed printable, supported by ongoing development. Materials in this category include aluminum, bronze, glass, and zirconia.

ExOne’s family of metal 3D printers includes the Innovent+, an entry-level system used globally for R&D, design and small part production; the X1 25Pro, a mid-sized production 3D printer that is large enough for most metal parts manufactured today; and the X1 160Pro, the company’s largest metal 3D printer that is expected to be released later this year.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Professor Chris Williams, Ph.D., working on 3D printing copper. Photo via ExOne.