A new study, published in Nature Communications, details the 3D printing of graphene oxide with a protein which can organise into tubular structures that replicate vascular tissues. The research is led by Professor Alvaro Mata at the University of Nottingham and Queen Mary University of London.

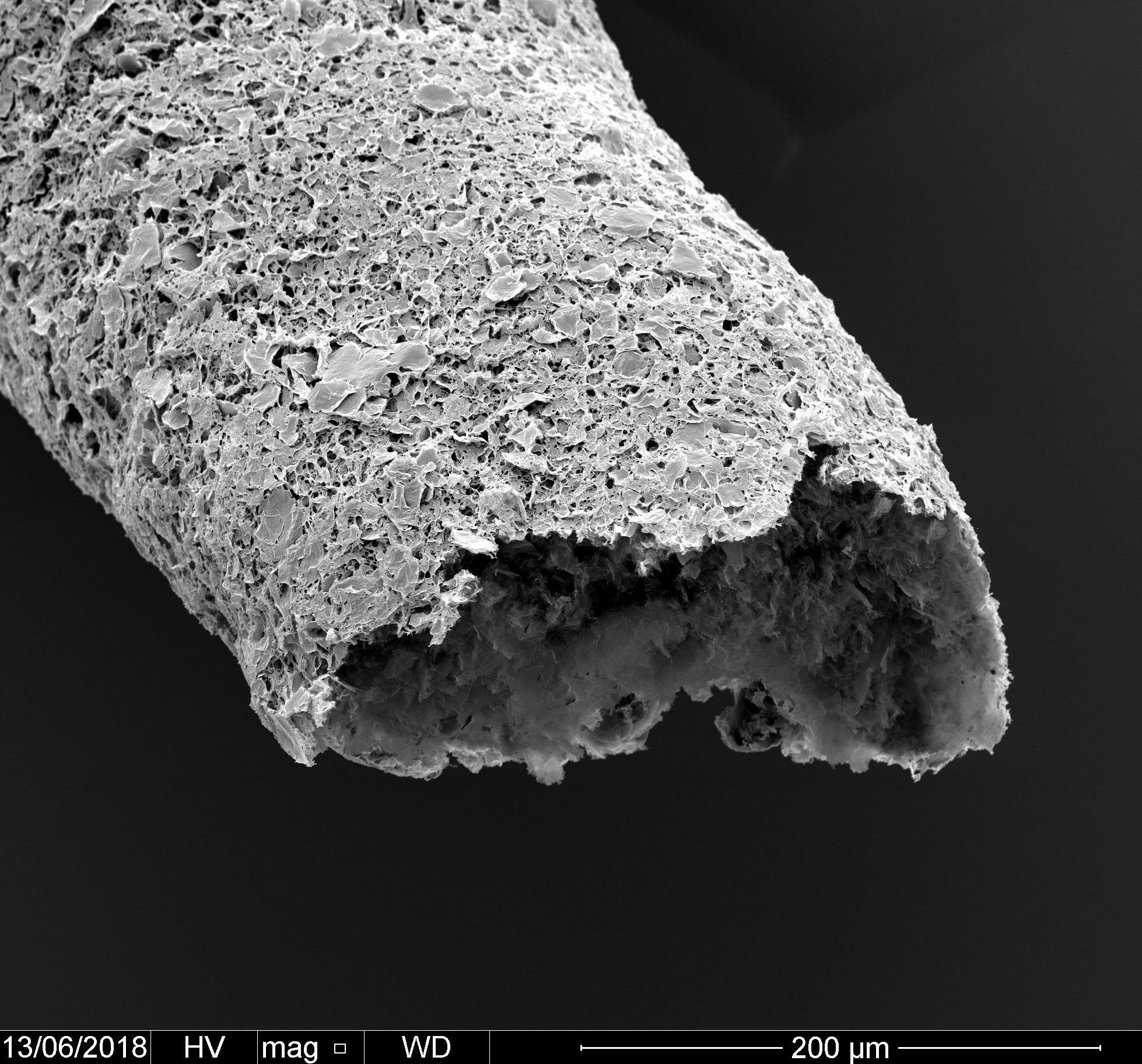

Professor Mata explains: “This work offers opportunities in biofabrication by enabling simultaneous top-down 3D bioprinting and bottom-up self-assembly of synthetic and biological components in an orderly manner from the nanoscale. Here, we are biofabricating micro-scale capillary-like fluidic structures that are compatible with cells, exhibit physiologically relevant properties, and have the capacity to withstand flow.”

Mata adds, “This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs, meaning treatments could potentially reach patients much more quickly.”

Self-assembling materials

The property of self-assembly is described as multiple components organising into larger well-defined structures, working in unison towards a common goal. Many biological systems rely on self-assembly to bring together molecular building blocks to assemble larger, complex systems exhibiting useful functionality. The life processes of growth, replication and repair all rely on self-assembly.

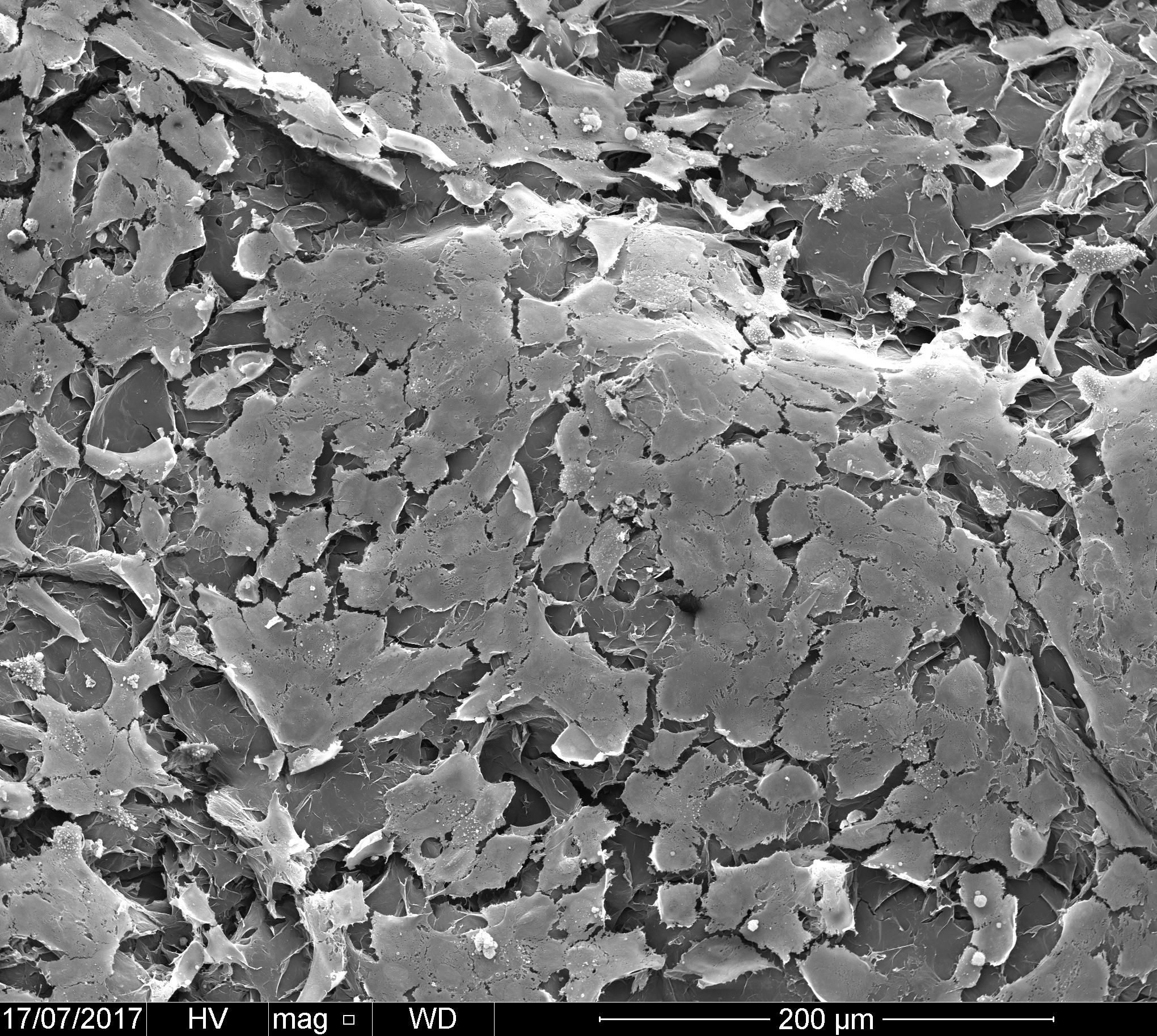

The new biomaterial discovered in the study is the result of the self-assembly of graphene oxide with a protein. The researchers observed the flexible, disordered regions of the protein conform to the more uniform structure of graphene oxide, fabricating a strong interaction between the two. By precisely controlling the way the two components are mixed, the scientists discovered it was possible to guide the assembly process in the presence of cells to produce complex, robust structures.

The end-result biomaterial can then be used as a bioink to 3D print intricate structures with fine resolutions. The team has successfully built vascular-emulating structures in the presence of cells. The structures developed in the study exhibited the relevant chemical and mechanical properties that allowed them to fulfil their purpose.

Dr. Yuanhao Wu, lead researcher on the project, stated: “There is a great interest to develop materials and fabrication processes that emulate those from nature. However, the ability to build robust functional materials and devices through the self-assembly of molecular components has until now been limited. This research introduces a new method to integrate proteins with graphene oxide by self-assembly in a way that can be easily integrated with additive manufacturing to easily fabricate biofluidic devices that allow us replicate key parts of human tissues and organs in the lab.”

Bioprinting around the world

Due to the criticality of bioinks in 3D bioprinting, much research has been conducted on the topic. New Jersey-based Rutgers University engineers have previously developed their own version of bioink that enables the construction of scaffolds to support growing human tissues. Significantly, the stiffness of the scaffolds can be controlled depending on the mixture of ink used, enabling applications for different types of tissues for repair or replacement.

Elsewhere, researchers in Chicago have also recently made progress towards bioink development, aiming to 3D print functional human ovaries. While the fabrication of whole organs is still expected to be decades away, these studies have yielded major accomplishments to progress the field of bioprinting.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows close-up of a tubular structure made by simultaneous printing and self-assembling between graphene oxide and a protein. Image via University of Nottingham.