Austrian technology companies, Ecoplus Plastics, and Mechatronics Cluster have published their findings on the application of additive manufacturing to industrial production. The companies began the €2.1 million Collective Research Network (CORNET) AM 4 Industry project two years ago.

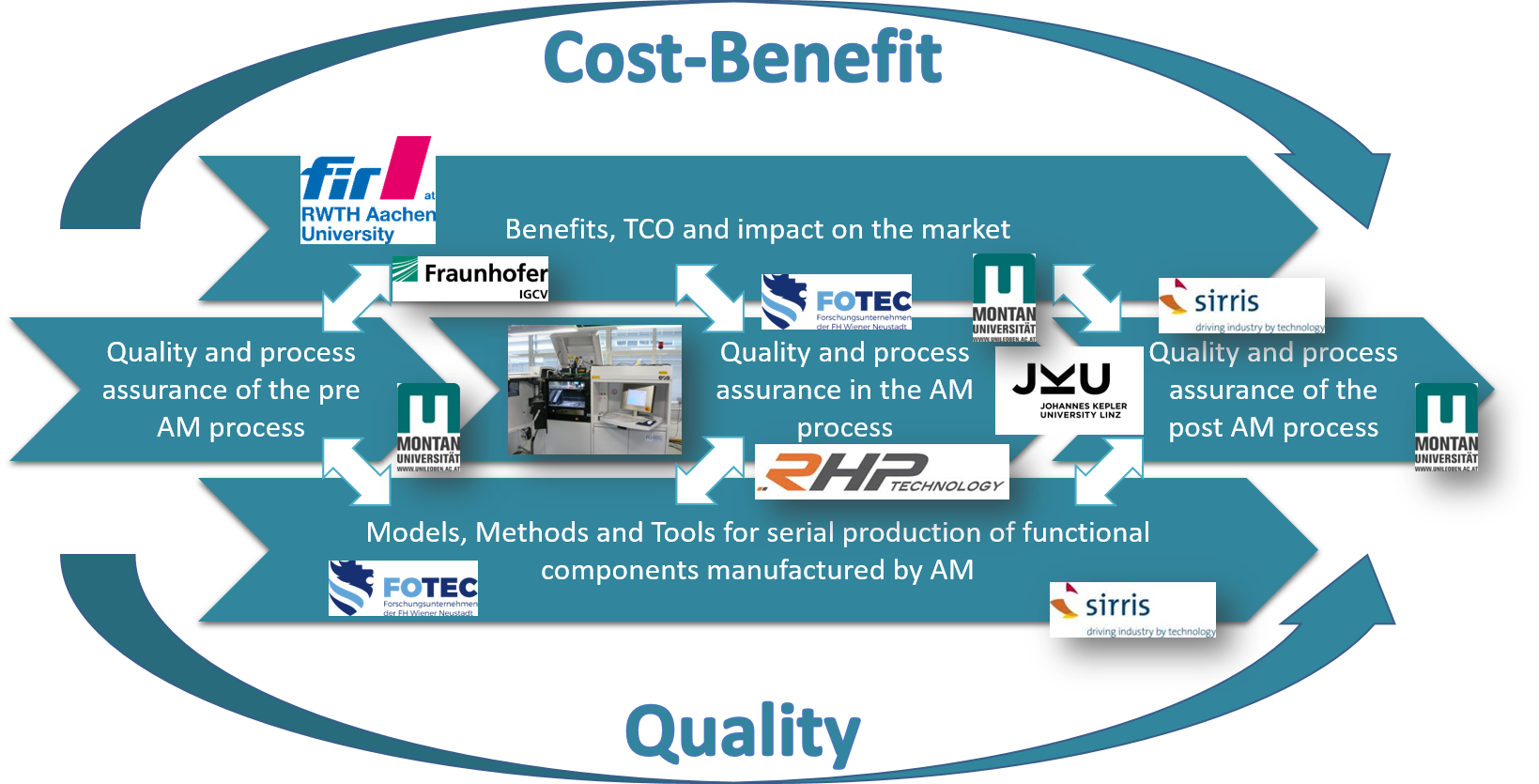

Ecoplus Plastics and Mechatronics Cluster work with eight research partners and fifty-one companies from Austria, Germany, and Belgium. RWTH Aachen University, FH, FOTEC and RHP-Technology GmbH were among the collaborating institutes.

The AM 4 Industry project

The aim of the project was to enable companies to make informed decisions regarding introducing additive manufacturing into production. The enterprises aimed to create a concept that aids an economic impact, including CO2-reducting as well as business efficiency.

The successful industrial application of AM technology depends on the definition of quality characteristics, and the development of methods for design and construction, according to the research. Reliable monitoring of production processes, suitable guidelines for reworking and an appropriate cost-benefit model are also claimed to be key factors.

The report consists of five publications:

- Laser beam melting (LBM) Additive Manufacturing Defect Catalogue

- Design for Additive Manufacturing: A feasible methodology

- Design in Additive Manufacturing Basic considerations related to processes

- Quality optimization and cost analyses to prepare the implementation of additive manufacturing processes

- Introduction to OpenFoam® and chtMultiRegion using an application-oriented example

Benjamin Losert, Project Manager at EcoPlus Plastics, commented on the project results: “Thanks to the expertise and the committed and open-minded cooperation of the partners involved, we were able to develop several methodologies and guidelines that will prove to be extremely relevant for the industry.”

Additive manufacturing in industrial production

Integrating 3D printing into production featured heavily at Formnext 2019. Exhibiting companies were aiming to provide customers with the tools to successfully implement the latest developments of AM technology.

This year’s TÜV SÜD Additive Manufacturing Conference was about digital solutions enabled by additive manufacturing. The aim of the event was to bring all stakeholders together who intend to use relevant materials and processes in the industrial context. The discussed topics included industrial readiness and optimal solutions to implement industrial 3D printing.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the AM4Industry User Committee Germany held its Kick-Off at Fraunhofer IGCV Augsburg on February 3rd 2017. Photo via AM4Industry.