New Jersey-based Rutgers University engineers have developed their version of bio-ink, which is made of living cells and used to 3D print scaffolds for human tissue growth.

The team originally set out to build a nerve graft for peripheral nerves but changed the focus of their work during the course of the study, eventually leading them to develop the new bio-ink at the end of the four years.

The work is published as a study in the biomaterial journal Biointerphases and led by senior author David Shreiber, a professor and chair of the Department of Biomedical Engineering, and lead author Madison Godesky, a recent doctorate graduate in biomedical engineering.

Shreiber stated: “We didn’t set out trying to design a bio-ink. We actually had a project that was a bigger collaboration with some other investigators here to build a nerve graft for peripheral nerves.”

Shifting the focus of the study

The initial project was focused on developing a tube and filler that would enable nerves to regenerate and lead them to where they would need to go during reconstructive medical procedures. The Rutgers team was responsible for developing the filler. They were planning on using Type I collagen as the filler material to do this.

Shreiber explains, “The collagen had proved to be incompatible with the tube and so we went looking for another filler. Then, as we were using another material, we recognized that it had potential for a bio-ink.”

The new bio-ink

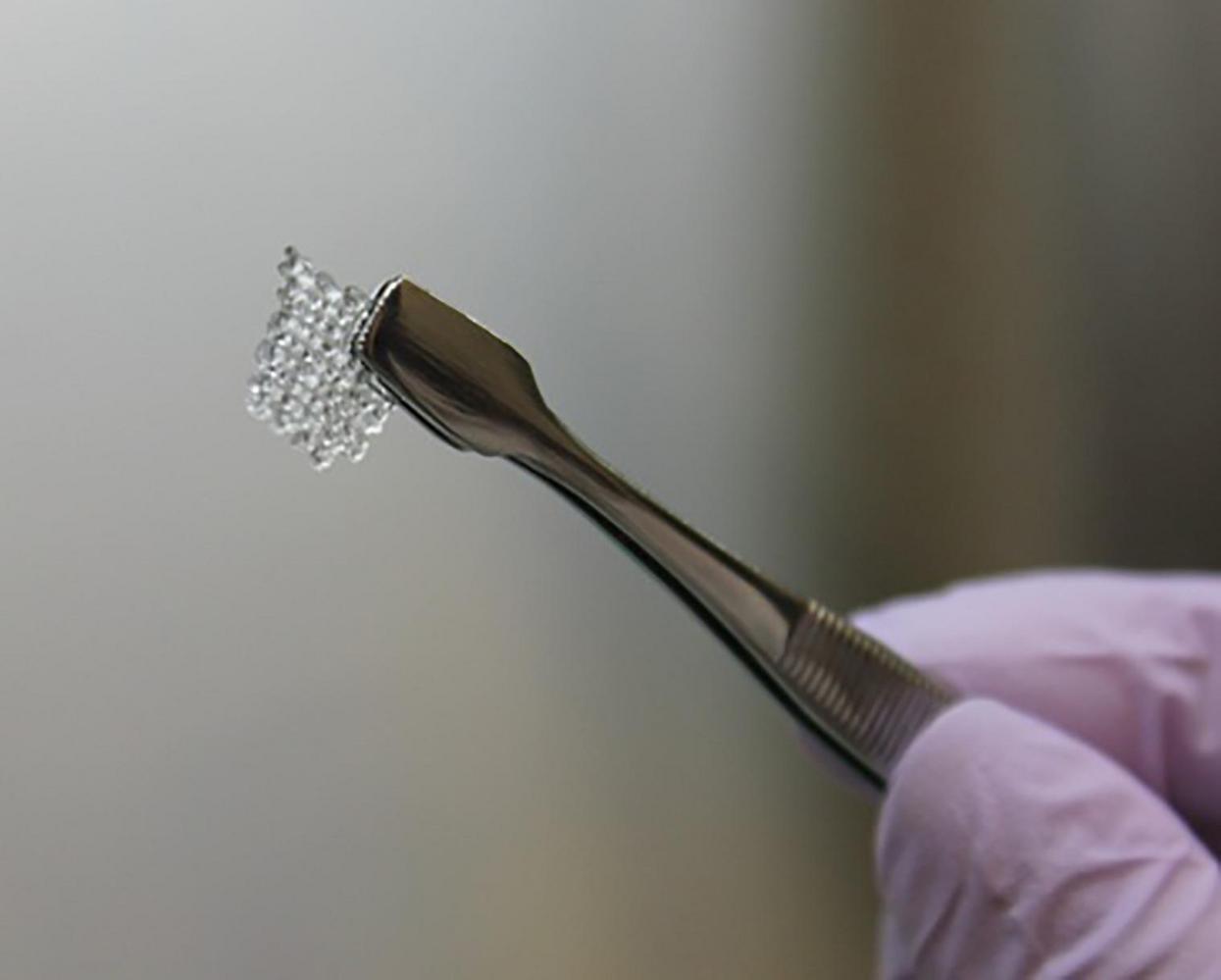

The ink is a gel consisting of hyaluronic acid and polyethylene glycol. The team wants to combine it with other inks in the future to customize its properties and use these new mixtures for various tissues.

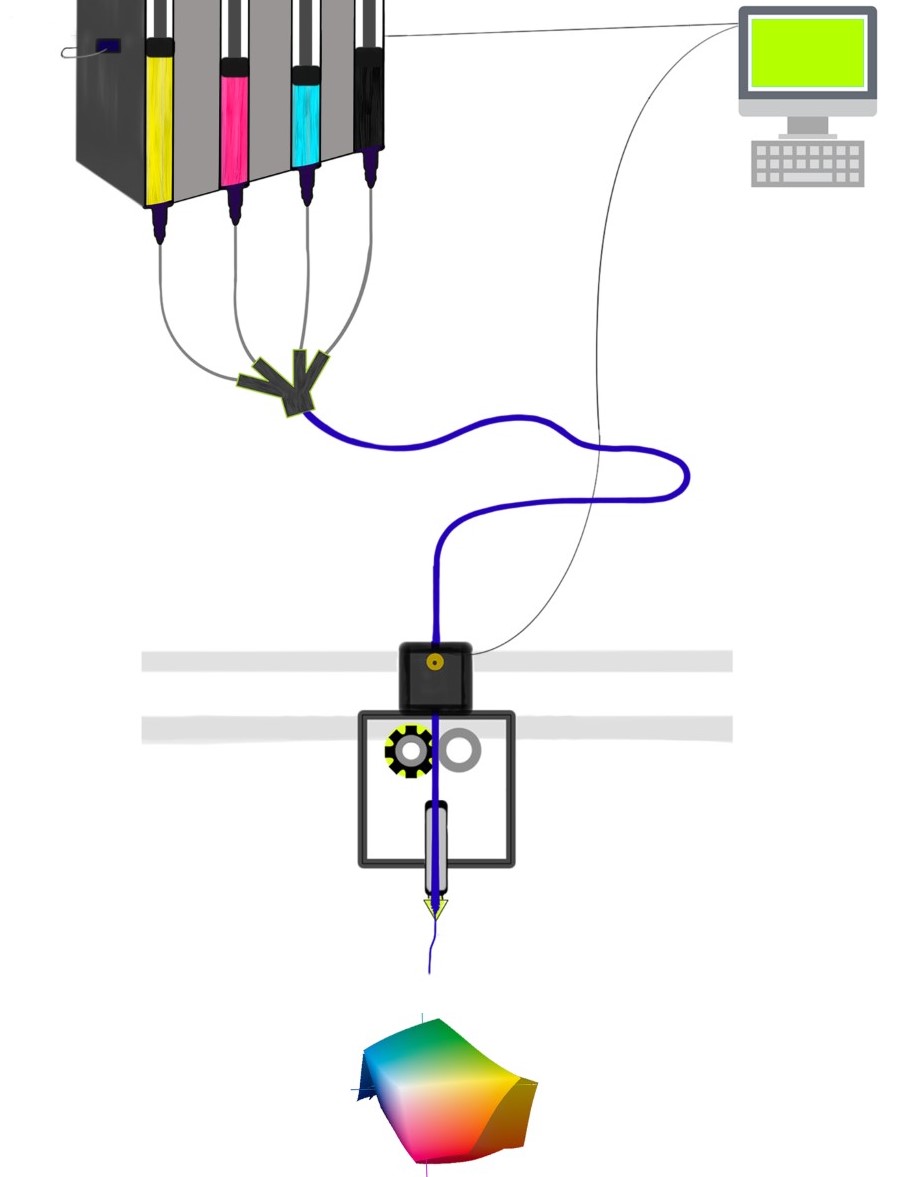

Shreiber elaborates, “Bio-inks are a lot like the ink jet cartridges in your printer: you want this color and you want that color, then you mix these for different combinations, we envisioned something like that. Cartridges, that when mixed, will control the stiffness, different ligands, different cells and you can customize what the properties are in specific locations.”

According to the study, what sets this bio-ink apart from others is the ability to precisely control its properties using mixing techniques. A major accomplishment in the study was the successful customization of the shapes of the produced scaffolds.

“3D printing is being used in things like dental implants and facial reconstruction, where you need something specific to a patient,” Shreiber states. “That’s kind of where the first 3D printing has assisted in regenerative medicine.”

He adds: “The thing about this work in regenerative medicine is that generally there’s not one person who takes something from the start and gets it across the finish line. Hopefully we figure all of the problems out, but there’s still a little ways to go before we’ll be printing livers and what not for an individual.”

The team plans to find 3D printing experts and make collaborative adjustments moving forward, advancing the field of tissue engineering.

Further details on the study can be found here.

Much research has been conducted on bio-ink in the past, as it is a critical component in 3D bioprinting. Researchers in Chicago have also recently made progress towards bio-ink development, aiming to 3D print functional human ovaries. Elsewhere, in Texas, researchers have developed their own version of bio-ink to 3D print scaffolds to transport protein for therapeutic purposes.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printing system with hyaluronic acid-based bioink. Image via Rutgers University – Madison Godesky.