Biomedical engineers from Rutgers University in New Jersey have developed a bio-ink for 3D printing that enables the construction of scaffolds to support growing human tissues. Significantly, the stiffness of the scaffolds can be controlled depending on the mixture of ink used, enabling applications for different types of tissues for repair or replacement.

Published in the journal Biointerphases, the researchers detail the use of modified versions of hyaluronic acid and polyethylene glycol to form a strong gel suitable for use as a scaffold.

“Instead of an ink color for an inkjet printer, we want the mixture to have properties that are right for specific cells to multiply, differentiate and remodel the scaffold into the appropriate tissue,” explains senior author David I. Shreiber, a professor who chairs the Department of Biomedical Engineering in the School of Engineering at Rutgers University-New Brunswick.

“We focus on the stiffness of the gel and scaffold binding sites that cells can latch onto.”

What is hyaluronic acid?

Hyaluronic acid is a natural molecule located within a number of tissues throughout the body. A clear, gooey substance, large amounts of hyaluronic acid are found in the skin, connective tissue and eyes. The skin naturally produces the substance in a bid to maintain its moisture levels, making it a common ingredient within skincare products. Researchers at the University of California in Los Angeles (UCLA) have also leveraged the substance to create a viable bioink for 3D printed pills.

The properties of hyaluronic acid make it ideal for the creation of customized scaffolds, however, it lacks the durability to act as a support structure. The team of researchers modified the hyaluronic acid by combining it with polyethylene glycol, a polyether compound with a variety of applications from industrial manufacturing to medicine. Through chemical reactions, the combined substances help to form a strengthened gel suitable for supporting tissue growth as a scaffold.

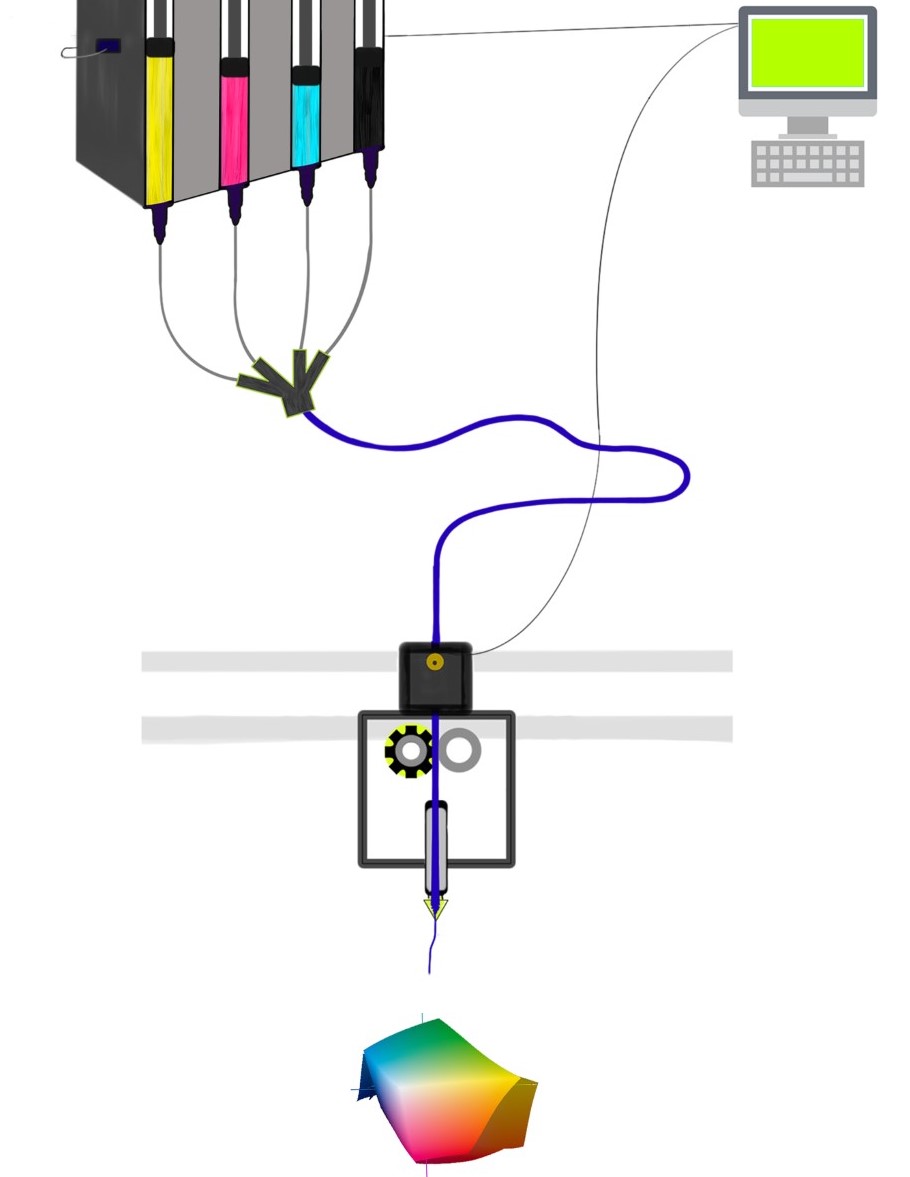

Shreiber, alongside the lead author of the study Madison D. Godesky, envisions a 3D printer in the study that would leverage the hyaluronic acid and polyethylene glycol mixture as ink cartridges within the system. Using this cartridge, the 3D printer would print gel scaffolds, or support structures, to help grow human tissues.

Additionally, the researchers also posit the inclusion of other ink cartridges featuring different cells and ligands to serve as the binding sites for cells. As such, the 3D printer would produce gel scaffolds with the correct amount of stiffness, cells, and ligands, according to the type of tissue in need of support. This enables scientists to tune the stiffness of the 3D printed tissue scaffold: “Both the stiffness and the binding sites provide important signals to cells,” Godesky added. “What especially distinguishes our work from previous studies is the potential to control the stiffness and ligands independently through combinations of inks.”

Supporting tissue growth in 3D printing

The subject of bioengineered tissues has gained significant traction within the fields of regenerative, precision and personalized medicine; product development; and basic research. Much of the topic’s recent developments have been supported by the advent of 3D bioprinting to produce scaffolds, or temporary structures to grow tissues.

For example, researchers at Lehigh University in Pennsylvania recently presented a new 3D printing platform enabling the regeneration of multiple tissues using spatially functionalized scaffolds. Furthermore, a team from the University Medical Center (UMC) Utrecht and École polytechnique fédérale de Lausanne (EPFL), Switzerland, have also developed a volumetric 3D bioprinting process inspired by visible light projection that creates free-form tissue structures.

As 3D printing continues to play an important role in regenerative medicine, 3D printer OEM 3D Systems opted to partner with Israeli bioprinting material developer CollPlant to create a tissue and scaffold bioprinting solution for third party collaborators. Through their collaboration, the two companies aim to combine their respective expertise in order to accelerate breakthroughs in the biomedical industry.

The research paper, “Hyaluronic acid-based hydrogels with independently tunable mechanical and bioactive signaling features,” is published in Biointerphases, and is written by Madison D. Godesky and David I. Shreiber.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

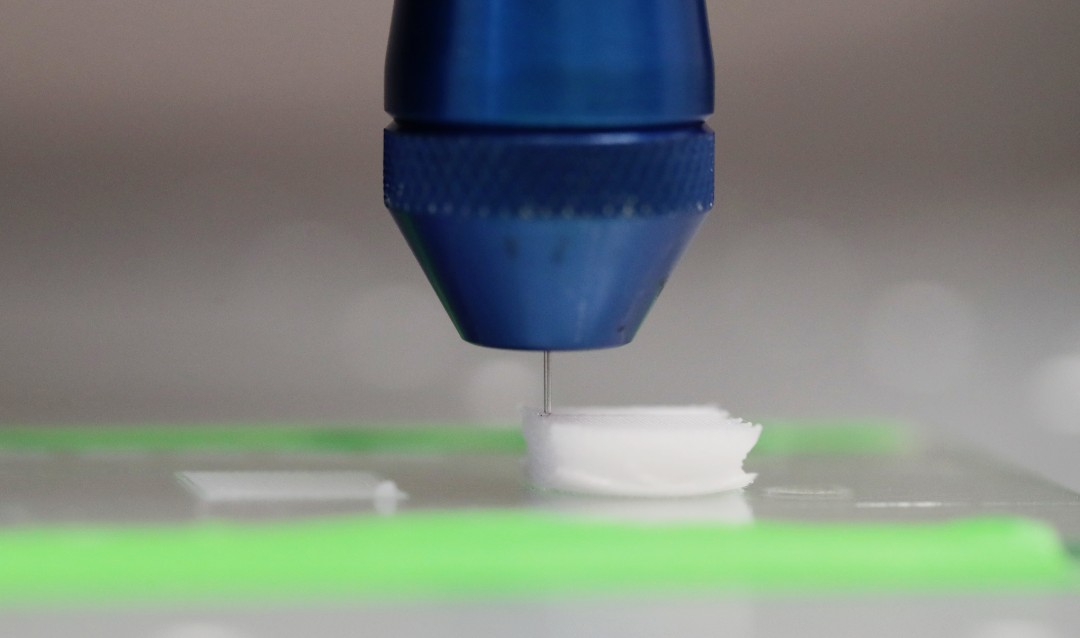

Featured image shows 3D printing system with hyaluronic acid-based bioink. Image via Rutgers University/Madison Godesky.