Researchers at Lehigh University in Pennsylvania have presented a new 3D printing platform enabling the regeneration of multiple tissues using spatially functionalized scaffolds.

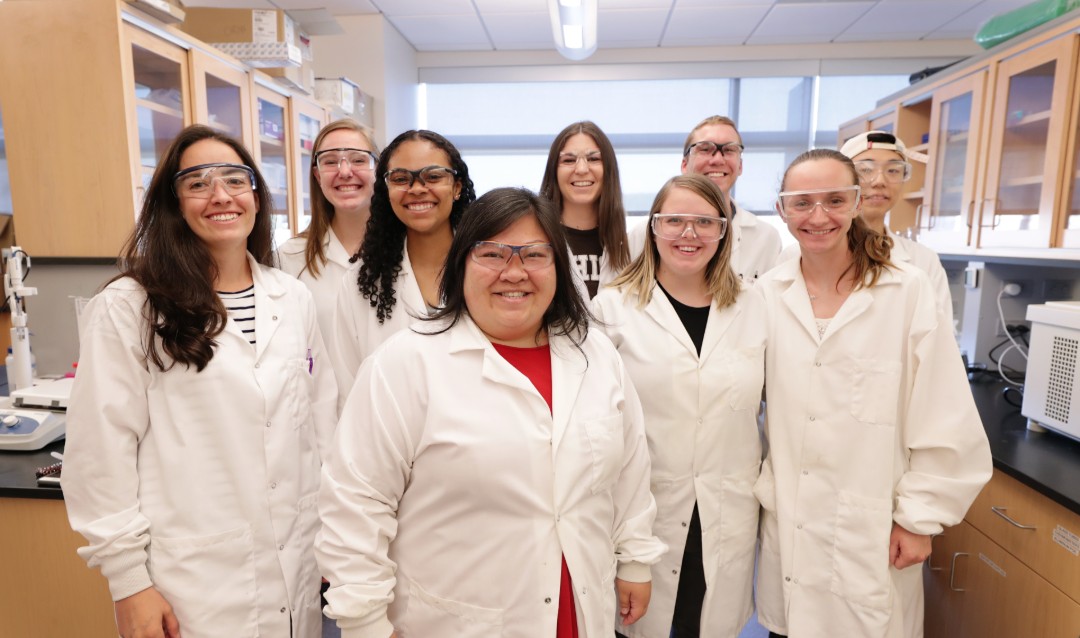

Lesley Chow, assistant professor of materials science and engineering and bioengineering at Lehigh, and her team at The Chow Lab, published a paper detailing how 3D printing highly organized biomaterial scaffolds can be used to regenerate two different tissues. The benefits of their method includes helping articular cartilage, which exists where bones meet at the joints, imitate the functional regeneration of other tissues. This could potentially prove useful in the treatment of osteoarthritis, a condition where damaged cartilage can cause joints to become painful and stiff.

“Our platform is designed to really control how cells arrange themselves,” explains Chow. “It’s like building a house and then seeing which house the cells like best. And we found that the cells really notice. They notice the two different cues. They notice whether the cues are organized or not organized.”

“We believe this presents a versatile platform to generate multifunctional biomaterials that can mimic the biochemical organization found in native tissues to support functional regeneration.”

Finding treatment for osteoarthritis

Unlike some tissues, cartilage is unable to regenerate as it lacks the blood vessels to enable such a process. Cartilage degeneration, which is accelerated by injury, therefore leads to osteoarthritis. Key to treating the condition is a consideration of both the bone and cartilage tissues operating together. “Medical intervention is the only way to regenerate osteochondral tissue,” Chow explains. “To successfully regenerate this cartilage and make it functional, we must consider the fact that function is related to both the cartilage and the bone. If the cartilage doesn’t have a good anchor, it’s pointless,”

“You could regenerate beautiful cartilage, but it won’t last if it isn’t anchored to that bone immediately beneath it.”

However, creating one organ made up of two different tissues (bone and cartilage) is a difficult task, and represents a huge engineering challenge. In an attempt to address the challenge, Lehigh’s Chow Lab, a team of research graduates and undergraduates led by Chow, have used 3D printing to fabricate scaffolds with spatially organized cues, enabling the control of cell behavior locally within one material. The scaffolds can then be used to regenerate two different tissues, such as those found in the osteochondral (bone-cartilage) interface.

Regenerating two different tissues simultaneously using 3D printed scaffolds

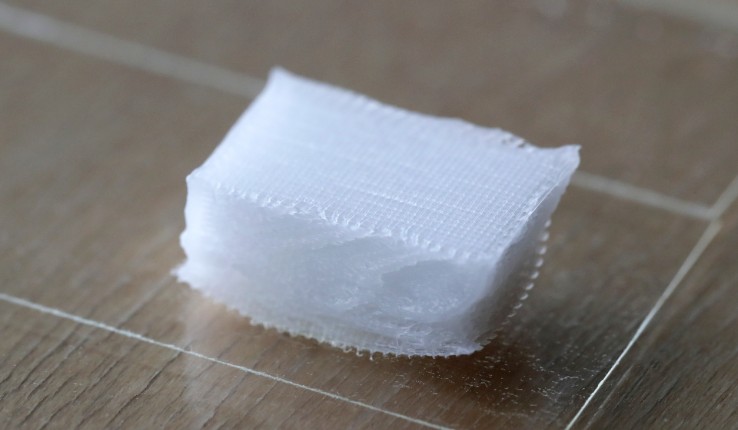

Scaffolds are utilized in tissue engineering to provide structural support for cells, as well as delivering chemical cues that direct the cells towards forming tissue, or becoming a different type of cell. Employed within the early stages of tissue regeneration, scaffolds are intended to be implanted inside the body, where they will then degrade as new tissue forms. Using its 3D printing platform, Chow’s lab has been able to create scaffolds made of biodegradable polymers.

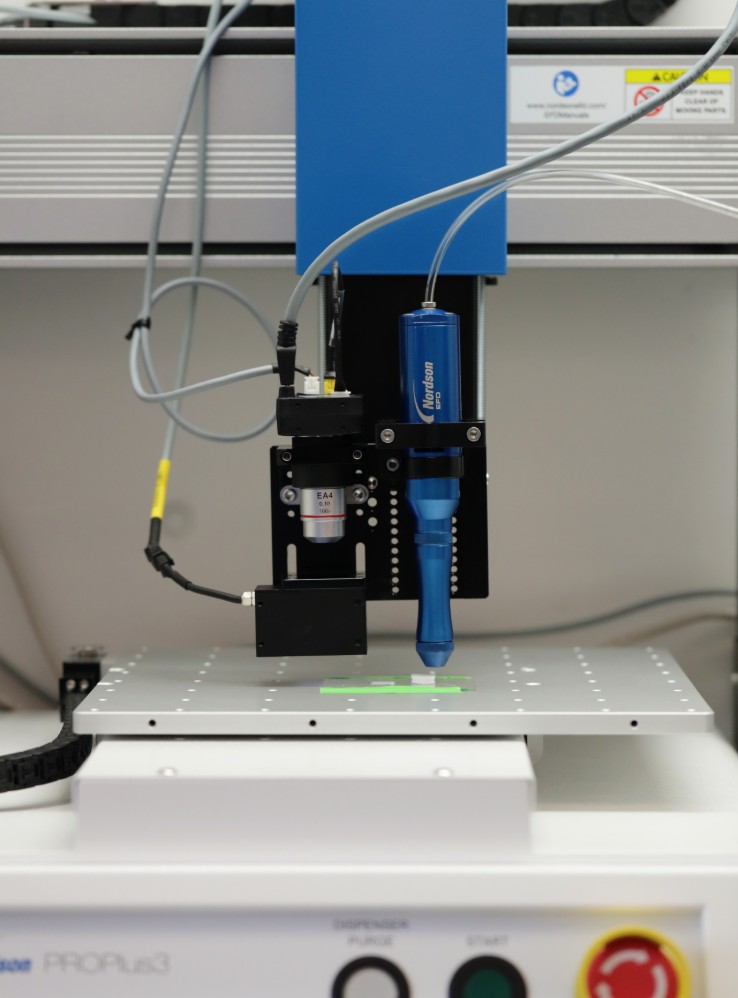

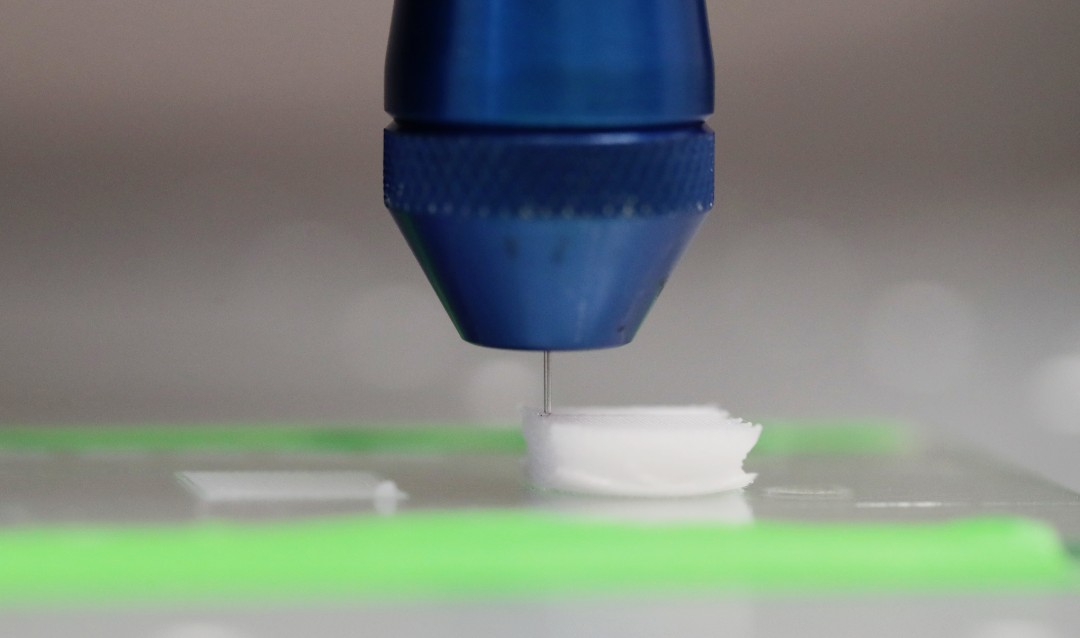

The scaffolds were biofabricated using a solvent-cast 3D printer, which is a 3D printing method that creates microstructures by depositing a liquid ink on a substrate, layer-by-layer. The solvent evaporates rapidly after extrusion from the deposition nozzle, leaving behind a solid 3D printed polymer fiber, in this case the scaffold.

To enable tissue growth using the scaffolds, Chow’s team inserted ‘functionalized’ polymers inside the inks, which are 3D printed to control the spatial deposition of different bioactive chemistries and architectures within the same construct. They prepared the inks by using a mix of biodegradable and peptide-modified polymers. Peptides are composed of amino acids, and are the source of the bioactive cues allowing for control over cell behavior. This allows the Chow Lab to replicate the compositions and structures of native tissues, therefore guiding cell behavior towards tissue growth.

“We know from literature and nature what amino acid sequences we want,” adds Chow. “We can take a segment that we know plays a specific and important role in telling cells to grow new tissue and, in a sense, steal from nature. We take a peptide and attach it onto a polymer and add that in while we are constructing our scaffolds.”

“We use 3D printing as a way to control the organization of these peptide-functionalized polymers as well as the scaffold’s architecture.”

Once the scaffolds have been 3D printed, they are implanted with cells that can be “tricked” by the peptides into becoming a different cell type. Chow explains that different inks can be loaded into the 3D printer in order to change the scaffold’s properties, like modifying the peptide concentration.

Paula Camacho, one of the graduate students on the Chow Lab team, is currently leading a project applying the scaffold 3D biofabrication platform to engineer the formation of osteochondral tissue. Cell-seeded scaffolds are cultured in an incubator at body temperature with 5 percent carbon dioxide, in order to mimic the conditions inside the human body. Camacho and her colleagues then evaluate the types of tissue that forms, and the behaviour of the cells. Although various other projects are also in progress using the 3D printing platform, the ultimate goal for the Chow Lab team is to extend its use for other researchers, and help move the field forward.

3D printing tissue structures

Various other research projects also looking at tissue growth and regeneration using 3D printing have been undertaken by various institutions. For example, recently researchers from the University of Birmingham developed a new 3D printing method for soft materials which could enable the manufacture of delicate soft tissues, complex soft tissue structures, and interfaced tissues.

A team from the University Medical Center (UMC) Utrecht and École polytechnique fédérale de Lausanne (EPFL), Switzerland, have also developed a volumetric 3D bioprinting process inspired by visible light projection that creates free-form tissue structures.

“3D printing with peptide-polymer conjugates for single-step fabrication of spatially functionalized scaffolds” is published in Biomaterials Science. It is co-authored by Paula Camacho, Hafiz Busari, Kelly Seims, Peter Schwarzenberg, Hannah L. Dailey and Lesley Chow.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows printer head on a solvent-cast 3D printer depositing the functionalized polymer inks layer-by-layer from a needle. Photo via Lehigh University.