Texas A&M University researchers have made bioink that can be utilized to 3D print scaffolds for transporting protein for therapeutic purposes.

The study published as “Printing Therapeutic Proteins in 3D using Nanoengineered Bioink to Control and Direct Cell Migration“, shows a method of producing biodegradable bioink with strong mechanical properties.

Dr. Charles W. Peak, co-author of the study, explained that with the help of the bioink, “the prolonged delivery of the bioactive therapeutic could improve cell migration within 3D printed scaffolds and can help in rapid vascularization of scaffolds.”

Bioinks and regenerative medicine

Scaffolds are extracellular structures capable of sustaining and migrating living cells. While the production of scaffold-making bioinks is common in 3D bioprinting, one persistence challenge is producing materials with both stable mechanical and biodegradable properties.

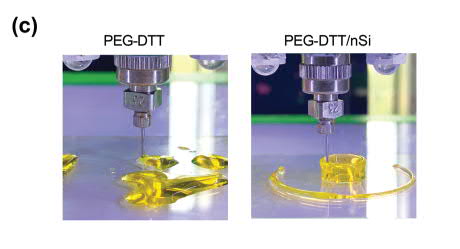

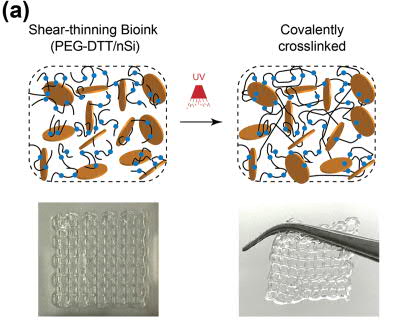

In the Texas A&M study, a bioink has been made using poly(ethylene glycol)-dithiothreitol (PEGDTT), a compound synthesized from a polyether with industrial and medical applications. The PEGDTT base material, which has low viscosity, was modified with 2D nanosilicates, single-layer nanoparticles, to make the bioink highly viscous so it could be injected through a syringe of a 3D bioprinter.

“To obtain shear-thinning bioink,” authors explains, “we added nanosilicates (nSi) (4% wt. vol−1) to PEGDTT. Our earlier studies have shown that 3–4% wt. vol−1 of nanosilicates are required to obtain shear-thinning characteristics.”

Once the bioink was printed, strong mechanical properties were obtained by UV curing, which formed covalent crosslinks to yield strength.

Releasing the protein

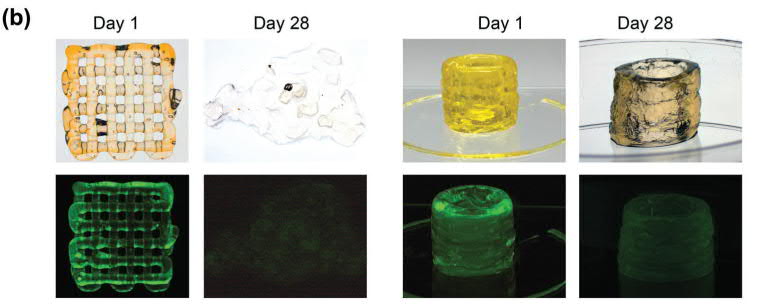

Following 3D printing, the PEGDTT scaffold was laced with a bovine protein, as a means of testing its utility. In this test, the scaffold showed a high cell viability of 85%. Results also argued that the Laponite XLG nanosilicate added to the bioink can prolong the release of therapeutic proteins. With the degradation of the scaffold structure, the protein was fully released within twenty-eight days.

“Shear-thinning bioink with the ability to sequester and release therapeutic proteins from 3D printed structure have been introduced,” the research concludes. “The bioink consists of degradable PEGDTT and 2D nanosilicates. The mechanical properties, swelling kinetics, and degradation rate can be modulated via the amount of PEGDA and nanosilicates.”

“Overall, this study provides proof of principle to print protein therapeutics in 3D that can be used to control and direct cell functions.”

The research discussed in this study was titled “Printing Therapeutic Proteins in 3D using Nanoengineered Bioink to Control and Direct Cell Migration“. It was published in Advanced Health Materials and was jointly authored by Charles W. Peak, Kanwar Abhay Singh, Mu’ath Adlouni, Jeffrey Chen, and Akhilesh K. Gaharwar.

To learn more about bioprinting subscribe to our newsletter and join us on Facebook and Twitter. Start a career in additive manufacturing with 3D Printing Jobs.

Featured image shows 3D printed scaffolds from day 1 till 28. Image via John Wiley & Sons.