In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest partnerships, acquisitions, medical developments and creative applications from across our industry.

Additionally, you’ll find out how 3D printing helped to miniaturize the tallest statue in the world; the novel technique used by law enforcers to help keep the Super Bowl secure; and what Brazil is doing to help accelerate additive manufacturing. Read on for the latest updates from the likes of Rize, 3D Systems, Essentium, Protect3d, Xioneer Systems and more.

XRIZE proves popular in education

Starting things off in education, Boston-based 3D printer manufacturer Rize revealed that the number of its educational customers increased three times in size during the second half of 2019. This has been attributed by the company to its Xrize™ color 3D printer, which reached general availability during the same period. Shipments of the 3D printer commenced in November 2019. As well as the Xrize however, educational sales in 2H 2019 have also been attributed to the Rize One 3D printer, which was awarded the UL 2904 GREENGUARD certification for safety and low emissions last year. Educational institutes that purchased 3D printers from Rize include Wentworth Institute of Technology in Boston, Georgia Piedmont Technical College, Rochester Institute of Technology and Wichita State University’s National Institute for Aviation Research (NIAR).

“It’s a new world in 3D printing and educational institutions are keen to prepare their students to lead it,” said Andy Kalambi, CEO of Rize. “We are delighted that Rize’s value proposition of providing intelligent parts and enabling smarter workflows in a safe and sustainable environment is enabling schools to prepare their students as the workforce of the future.”

Rize has also announced a partnership with Korea’s Sindoh. 3D printing materials from Rize will be available to Sindoh customers for use on the Sindoh 7X and 3DWOX line.

Over in research, KRAIBURG TPE, a global manufacturer of thermoplastic elastomers (TPE), has performed rigorous tests on the compatibility of the company’s TPEs for use in additive manufacturing. From the tests, the company concluded that the most suitable FFF 3D printer for processing its TPE material is the pellet additive manufacturing (PAM) system from French 3D printer manufacturer Pollen AM.

“Due to physical limitations, most classic 3D filament printers are not suitable for processing soft TPEs. In addition, it’s only possible to draw fairly limited conclusions from prototypes made of special 3D printing materials in relation to the performance of standard injection molding or extrusion compounds,” comments Dr. Thomas Wagner from Product Management EMEA at KRAIBURG TPE.

“The challenge we faced was to precisely analyze the prerequisites for fused deposition modeling of soft TPEs. In order to find a suitable solution, we had to learn to separate the technical limitations of the printers from those of the materials.”

3D printing news in medical, healthcare, dental and biotechnology

In medical news this week, Essentium Inc., a Texas-based 3D printer provider, and Canadian CAD/CAM software developer Vorum have announced a partnership combining their respective technologies to create a 3D printing solution for the global Orthotics & Prosthetics (O&P) Market. The package, designed to allow the production of customized O&P devices at speed and scale, includes Essentium’s High-Speed Extrusion (HSE) 3D printing technology and materials, combining it with Vorum’s O&P CAD/CAM solutions. Blake Teipel, CEO and Co-Founder, Essentium states: “Our ground-breaking 3D printing platform combined with Vorum’s expertise will not only help O&P customers embrace a faster, more efficient method for producing custom-made orthotics and prosthetics, but the medical devices will also be produced with high quality and durability. Together we are re-writing the business and production model for O&P professionals that bring profoundly important mobility and independence to their patients.”

Further news from Essentium this week: the company has announced a partnership with British 3D printing reseller GoPrint3D. As such, GoPrint3D will now resell Essentium’s HSE 3D printers in the UK and Irish markets. This includes all the printers in Essentium’s HSE 180-S range, as well as the company’s materials. In October 2019, Essentium announced a series of expansions in response to growing demand for its HSE 3D printing platform. These include scaling up the production of the HSE FDM 3D printer, accelerating material development, and expanding global operations with new leadership appointments.

Protect3d, a North Carolina-based medical device startup, has received $50,000 from the National Football League (NFL). Awarded to the company as part of the NFL’s 1st and Future competition, the money will be used to develop Protect3d’s 3D printed medical device solution for injured athletes. It involves an app that allows users to scan an athlete’s body upon injury, which is then converted into 3D models for the Protect3d team to 3D print and deliver to the user. Protec3d received the top prize against four other startups in the category of Innovations to Advance Health and Safety. The NFL is increasing its measures to protect its players, and 3D printing is proving a popular avenue that the league’s organizers are exploring. Partnering with America Makes, the NFL is also running a Helmet Challenge that will award up to $2 million in grants to experts, innovators, and helmet manufacturers to develop a prototype for a 3D printed NFL helmet.

Singapore based dental 3D printer OEM Structo, has partnered with German medical 3D printing materials company, pro3dure. The partnership will provide users of Structo’s Velox 3D printer access to pro3dure’s range of dental 3D printing materials, which enables applications for splints, surgical guides, indirect bonding trays, and temporaries. Recently, Structo closed its latest funding round backed by government-linked global investor EDBI, enabling new automated products for mass production.

Texan medical device company Osseus Fusion Systems has announced the Alpha launch of its 3D printed transforaminal lumbar interbody fusion (TLIF) device, called Aries-TS. TLIF is a procedure that fuses the anterior and posterior columns of the spine through a posterior approach. The Aries device is 3D printed in titanium with a lattice structure, optimized for bone fusion and biological fixation using Osseus’ proprietary SLM 3D printing technology known as PL3XUS. This technology enables the production of implants that are 80 percent porous. Osseus initially received FDA clearance for an older version of Aries in 2018, and last year the company partnered with 3D printing service bureau PrinterPrezz to develop applications for the next generation of Aries devices.

Korean 3D bioprinting firm T&R Biofab has signed a research collaboration agreement with Ethicon, a subsidiary of American multinational corporation Johnson & Johnson that manufactures surgical sutures and wound closure devices. The research collaboration surrounds the development of 3D bioprinted soft tissue scaffolds using T&R Biofab’s technology. These scaffolds can potentially provide support to repair, elevate, and/or reinforce anatomical and structural deficiencies, therefore enabling applications like wound closure, wound patches, hernia repair, hand surgery, tendon repair and more.

A number of partnerships in the 3D printing industry this week

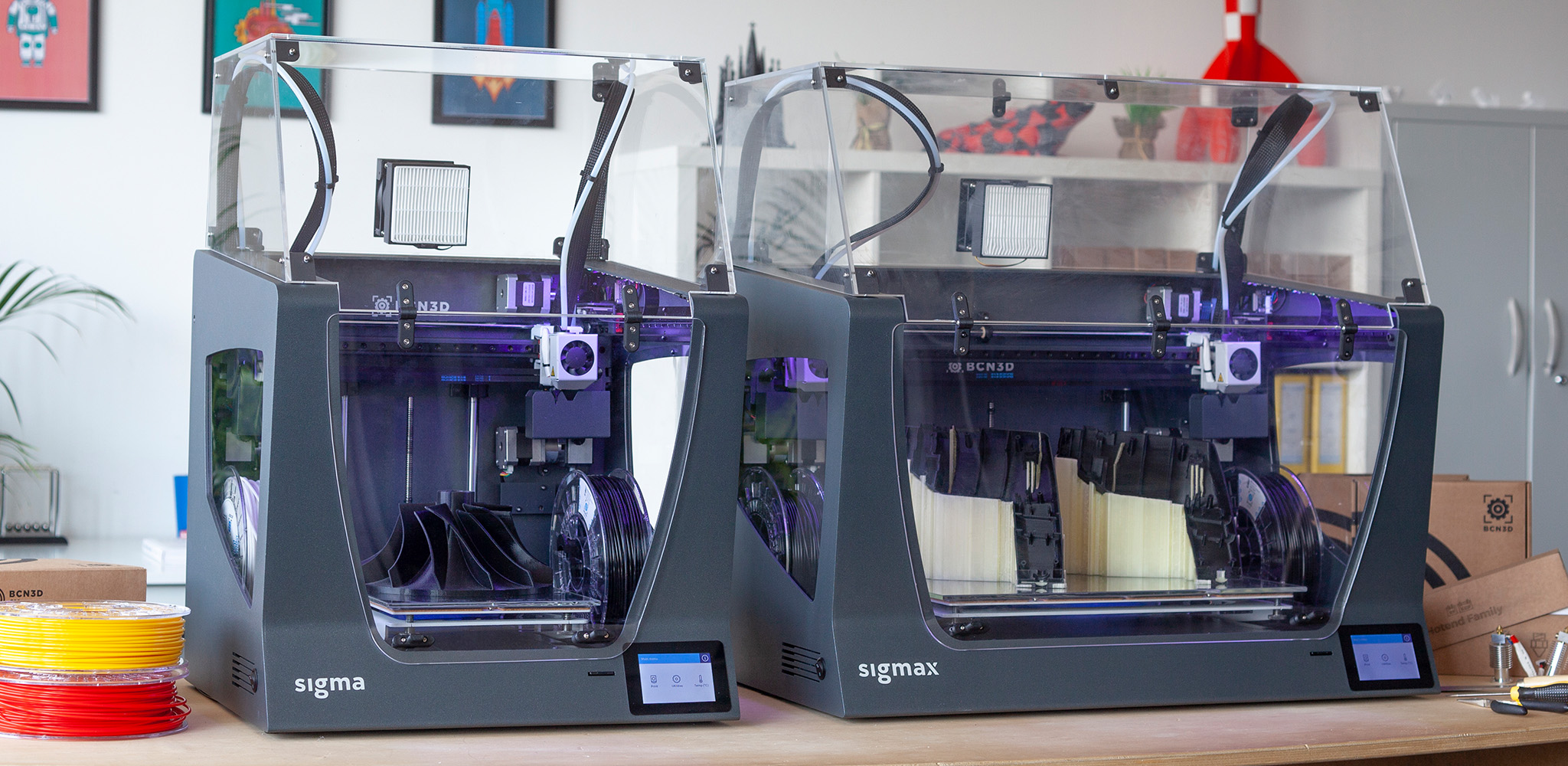

Tensabelt, a manufacturer of queue management system devices, has used 3D printers from Barcelona-based BCN3D Technologies to improve the fabrication process of its tooling. Due to increased demand for its products, the company sought an efficient solution for producing custom tooling, in order to boost its manufacturing process. By integrating a BCN3D Sigmax 3D printer within its workflow, the company has been able to quickly fabricate new tools with more functional designs. Manufactured in PLA, the tools can be customized to the task required, and produced within 24 hours, reportedly saving Tensabelt up to 200€ per piece. “With additive manufacturing, we fabricate jigs and fixtures, such as the pieces we use to mechanize the parts that come from our plastic injection molds”, explains Clara Bazán, Tensabelt’s Global Production Manager.

The National Institute of Metrology, Standardization and Industrial Quality (INMETRO) in Brazil, through its Division of Materials Metrology, Dimat, has partnered with FARCCO Tecnologia to help accelerate the use of additive manufacturing within industrial production processes in Brazil. FARCCO Tecnologia is a metal 3D printer reseller in Brazil, whereas INMETRO is a federal accreditation autarchy. Working together, the aim of the partnership is to establish a portfolio of new INMETRO services for increasing the technological capacity of Brazilian companies in additive manufacturing.

U.S. 3D printer manufacturer 3D Systems has announced that it has expanded its relationship with Sanmina, an integrated manufacturing service provider. Initially, the two companies were engaged in a multi-year partnership that involved the manufacturing of the Figure 4 platform of 3D printers. However, the expanded partnership will now see Sanmina help to manufacture 3D Systems’ entire line of plastic 3D printers. “Three years ago, 3D Systems set out to have world-class manufacturing capabilities for our products,” said Phil Schultz, executive vice president, operations, 3D Systems. “We’ve had an ongoing relationship with Sanmina to manufacture our Figure 4 platform, and their expertise with our products, their commitment to quality, their understanding of our operations is incredibly valuable. We’re confident that this expanded relationship with Sanmina will allow us to continue to deliver best-in-class solutions to our customers and will provide 3D Systems greater competitive advantage through a lower cost-structure.”

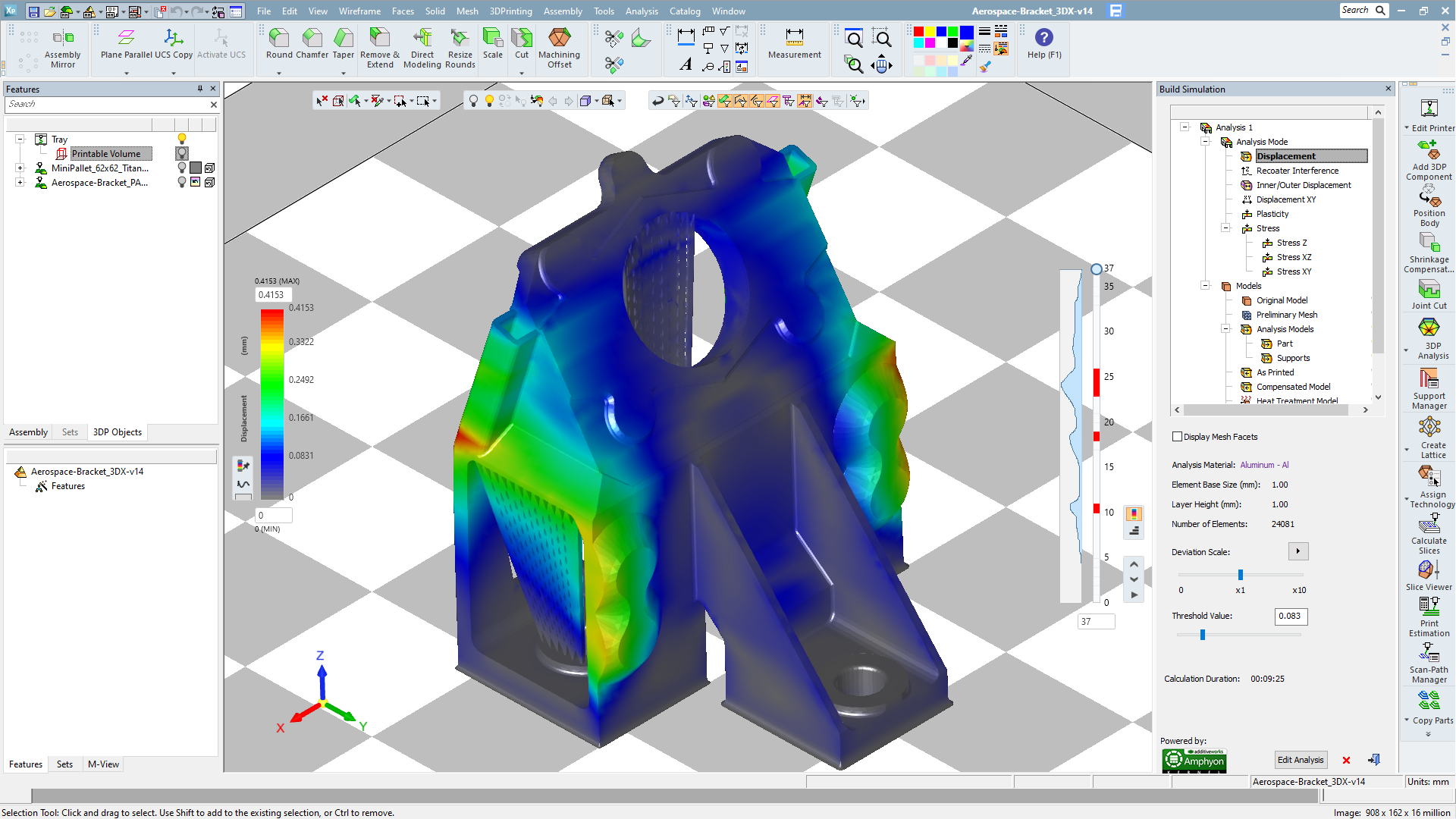

In a separate announcement, 3D Systems has also launched the latest version of its software 3DXpert for SOLIDWORKS. Announced at 3DEXPERIENCE World 2020, the updated features of 3DXpert for SOLIDWORKS 15 includes bi-directional data transfer, intended to shorten the design cycle, an enhanced lattice development suite to help optimize design structure, and new automated tools and workflows to support the printing process. 3DXpert for SOLIDWORKS was first announced in 2018 and was designed to help SOLIDWORKS users prepare and optimize their designs for additive manufacturing.

In early January, the National Institute for Occupational Safety and Health (NIOSH) announced a partnership with America Makes, the Ohio-based national accelerator for additive manufacturing, to advance the knowledge and practice in additive manufacturing and 3D printing research in the workplace. In particular, NIOSH will be contributing its guidance and expertise on the subject of workplace safety practices, for both employers and workers, in regards to additive manufacturing. “We are pleased to enter into what promises to be a collaborative and creative partnership with America Makes,” said NIOSH Director John Howard, M.D. “By working alongside industry, academia and other government partners, we can together leverage existing resources, collaborate, and co-invest to advance manufacturing innovation.”

Thinklaser, a UK-based developer of laser-based manufacturing systems has announced partnerships with 3D printer manufacturers Roboze and Admatec. Roboze is an Italian 3D printer manufacturer, whereas Admatec is based in the Netherlands. With the new partnership, Thinklaser will now be able to distribute both Roboze and Admatec’s 3D printers to the UK market.

Acquisitions and funding

Xioneer Systems, an Austrian 3D printer manufacturer, has been acquired by BellandTechnology AG, a German chemical company. With the acquisition, BellandTechnology aims to expand its global presence on the markets for 3D printing and additive manufacturing. Xioneer was founded in 2013, and develops FFF 3D printers for the professional market. “By merging our companies, we combine the 3D printing know-how of Xioneer with the materials know-how of BellandTechnology. And this places us in a unique competitive position: a position to tackle 3D printing challenges in a new way, to deliver new solutions. All that with one goal in mind: to promote the FFF technology in both the consumer and the industrial additive manufacturing markets,” explains Dr. Andrei Neboian, founder and CEO of Xioneer.

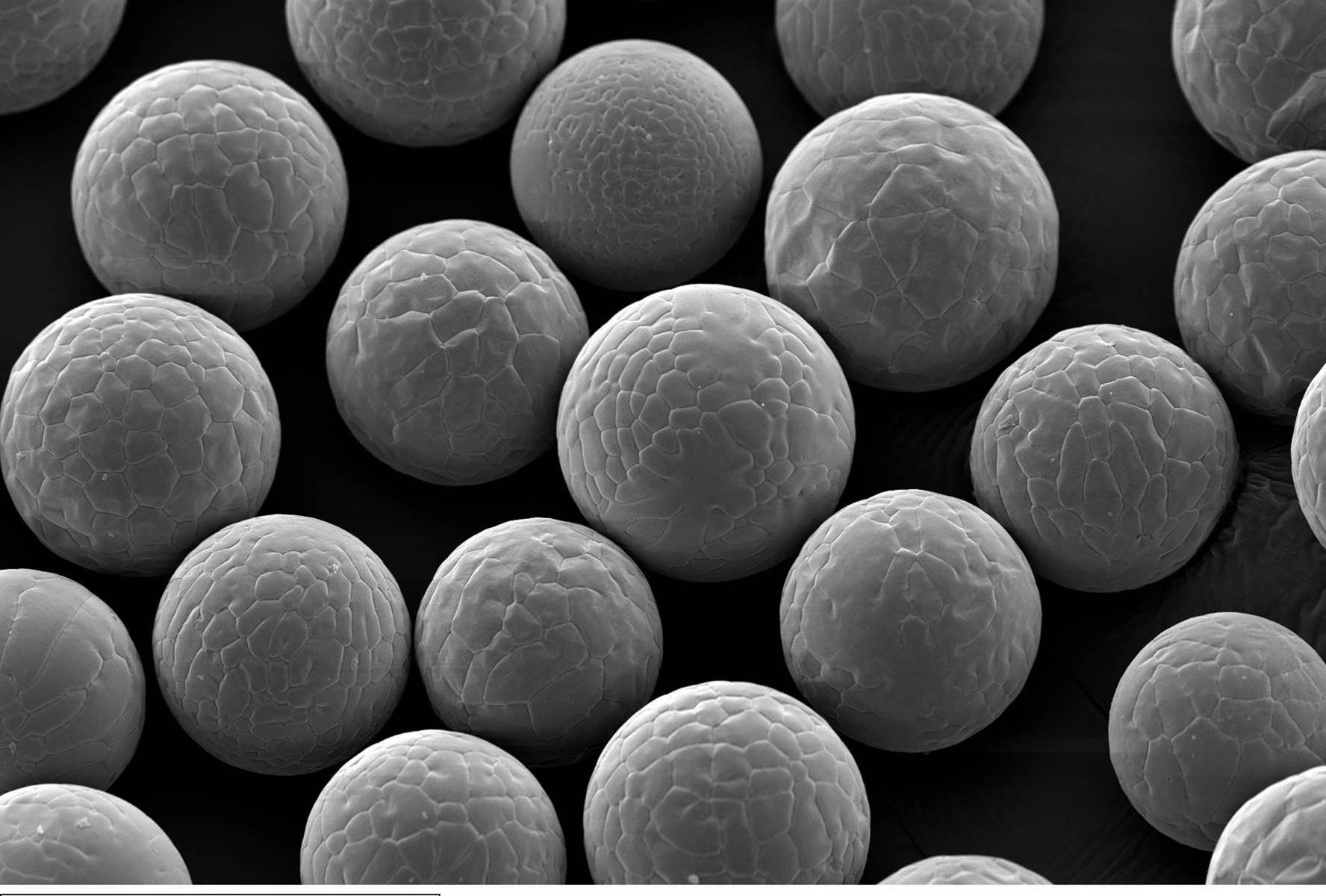

Equispheres, a Canadian metal additive manufacturing powder manufacturer, has been awarded $8 million in funding from the Sustainable Development Technology Canada (SDTC). SDTC is an initiative established by the Government of Canada to help Canadian entrepreneurs accelerate the development of clean technology solutions. The funding will be used by Equispheres to scale its metal powder production capacity over the next two years. “We are excited to receive this funding award from the SDTC Foundation,” states Kevin Nicholds, CEO of Equispheres. “This support from SDTC speaks to the importance of our powder technology as a key to achieving significant emissions reductions in the automotive sector. The funding from SDTC will help Equispheres to continue to accelerate our production capacity and support this important work by our automotive partners.”

Staffordshire-based 3D printing service provider Midlands 3D has announced that it has acquired fellow UK-based 3D printing service bureau Lancashire3D, which is based in North West England. The acquisition will add additional capacity and services the Midlands 3D printing service which, as the company responds to increasing demands for FDM 3D printing. Through this acquisition, the Lancashire3D brand, contact details, and website will be transferred to Midlands 3D. “Our two businesses have grown significantly over the past four years based around very similar business models, so when the opportunity to join forces came about, it was an easy decision,” remarked Paul Moloney of Midlands 3D. “The team at Lancashire 3D has developed an enviable presence in the market, a great customer base and a strong brand based around sustainability and environmentally friendly 3D printing, which we will be embedding into the combined operation”.

Creative applications of 3D printing

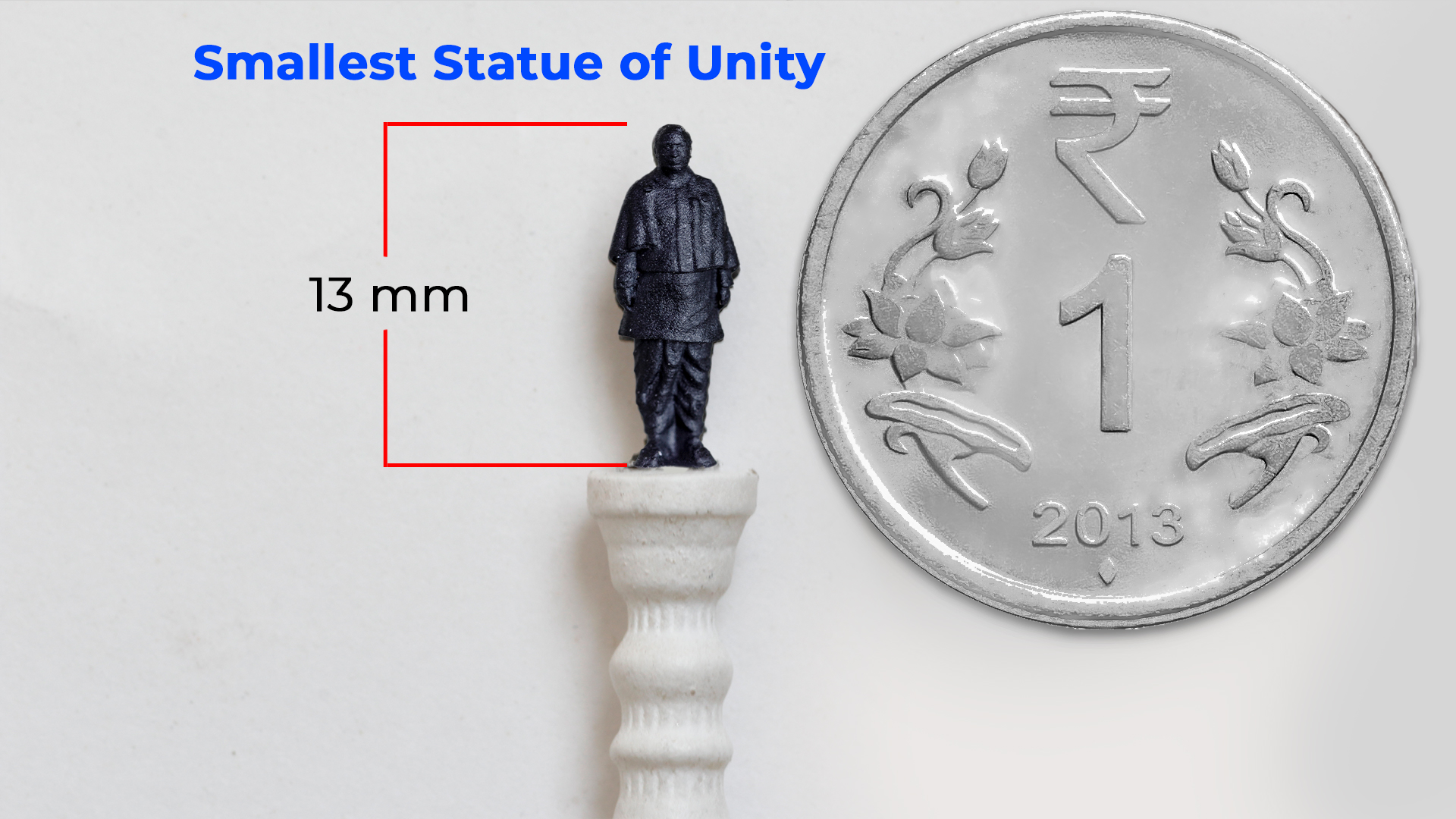

Indian additive manufacturing service provider STPL3D has produced what is known to be the world’s smallest 3D printed replica of the Statue of Unity, the colossal 182m statue honoring statesman and independence activist Sardar Vallabhbhai Patel in Gujarat. The 3D printed miniature on the other is measured at a measly 13mm. Using SLA 3D printing, STPL3D was able to 3D print the replica with increased detail.

3D printing has been employed by Mina Jang, a professional flutist, and researcher in baroque music, to make a replica of an original musical instrument capable of producing the same sound. The original instrument is a handmade version of an original early 18th-century flute crafted in 2001. The 3D printed replica, on the other hand, is made from plastic. Produced for the Museum of Music in Paris, a 3D printed replica was produced as the museum is seeking to establish a method allowing improved preservation of its period instruments. Significantly, 3D printing increases the speed it takes to manufacture an instrument, compared to traditional handcrafting methods. Prior to 3D printing, the 18th-century flute was scanned to identify its precise characteristics, enabling the recreation of its sound characteristics.

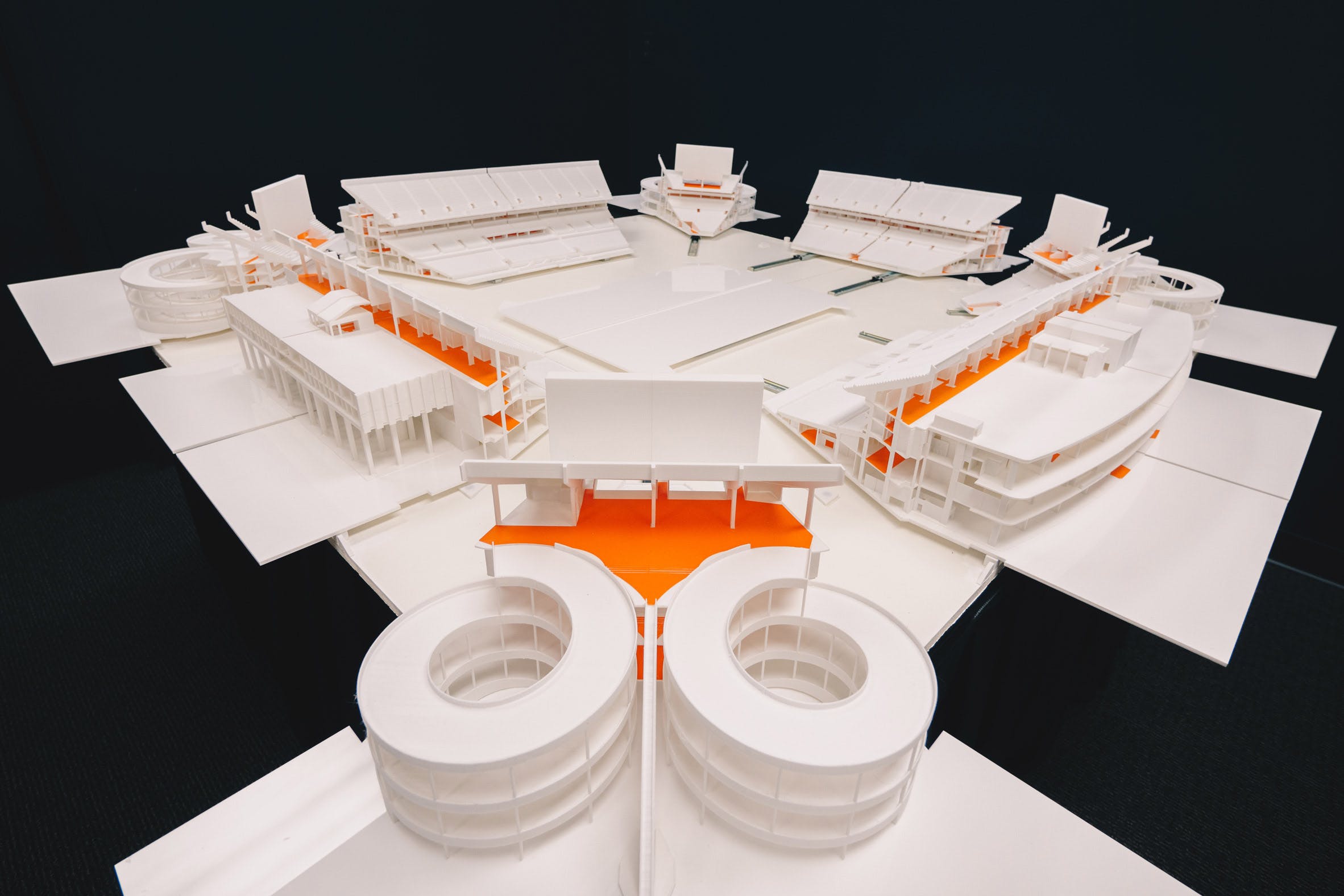

As well as potentially playing an integral part in ensuring the health of NFL players, 3D printing has already proved integral in ensuring the safety of both those on the field as well as the visitors. In preparation for the NFL’s most popular event, the Super Bowl, the Miami-Dade Police Department (MDPD) leveraged a highly detailed 3D printed model of the Hard Rock Stadium, where the Super Bowl took place. The detailed model, created by students at Florida International University (FIU), details the stadium’s hallways, exits and rooms, and much more, taking over 3500 hours to 3D print. It was produced from months of examining digital documentation of the stadium. This detail allowed the MDPD to fully prepare for the event. “This was something unique, for FIU and MDPD, the creation of a physical model to use in training,” said Professor Shahin Vassigh, who is the director of the RDF Lab. “It’s not necessarily the scale that is unique – architects make models for demonstration regularly – but the intricacy of details and this type of collaboration.”

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on an image of uniform particles of Equispheres aluminum alloy powder. Image via Equispheres.