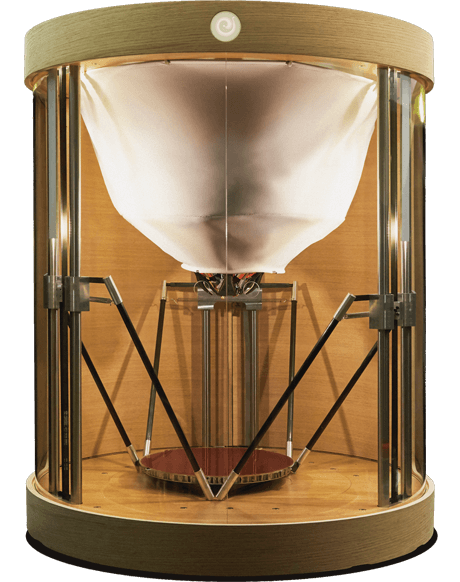

Last week I sat down with Cedric Michel, co-founder and CEO at Pollen AM. The French company is the developer of the Pellet Additive Manufacturing (PAM) system, the technology at the core of the Pollen AM Pam Series P FDM 3D printing technology and also used in company’s Pam Series M metal 3D printers.

From a dream to a startup

Pollen AM was founded in 2013 by friends Cedric Michel and Victor Roux. Michel had his first experience with 3D Printing while a student at Imperial College in 2001.

At the time, operating a 3D Printer was more significantly more complex and costly than presently. However, the Pollen AM CEO understood the potential of a technology that granted him the freedom to make almost anything.

This initial excitement led to a desire for building a business in the 3D printing industry. By 2009 Michel was brainstorming with Victor Roux on how they could contribute to the 3D printing revolution. It took them 4 years to refine their ideas and to create Pollen AM in 2013.

A Vision: pellets offer significant benefits from any other 3D printing materials

Michel’s vision is founded on the benefits of using pellets, rather than more widely used filament, as the feedstock for an additive manufacturing production factory. He explained that pellets are significantly cheaper than traditional 3D printing materials, plus they easily available in a wide range of formulations and of superior quality.

Despite the obvious benefits, direct use of pellets is relatively rare. Leading to some claims that designing a system to run on the more expensive filament products is a way for early developers to recoup initial investments.

By using pellets as the feedstock for their 3D printers, Pollen AM believes they have a tremendous opportunity. Over the past 4 years the company has invested time in developing the right machine to extrude pellets into quality 3D printed objects. This has not been an easy task, and Michel acknowledged the difficulties in bringing to market the right machine.

Given the limited number of FDM 3D printers running on pelletized feedstock, it is fair to say that Pollen AM is not alone in experiencing this difficulty. Italy’s WASP is one company that has developed such a 3D printer – the DeltaWASP 3MT. More recently we covered the launch of the Titan Robotics Atlas.

The Palm P 3D printer

The Pollen AM Palm P additive manufacturing system is the result of the company’s perseverance. The 3D printer uses 4 extruders, allowing for multi material 3D printing. During our conversation Michel was keen to highlight the versatility offered by the pellets, that allow the Palm P to 3D print objects at 40 shore A softness.

Funded EUR2.5M since 2013

Currently Pollen AM operates from its facility on the outskirts of Paris, at Ivry-Sur-Seine. Total headcount is 10 full time employees and 2 part time. Pollen AM is also working with manufacturing and R&D partners located in France. To finance its development Michel decided in 2013 to raise funds from professional investors with strong industrial and financial expertise. As of today the company successfully raised EUR2.5M over 5 rounds. Pollen AM’s promising technology and successful execution has attracted some high profile private investors including Bruno Maisonnier and Serge Verdier.

Bruno Maisonnier, is the founder and former CEO of Aldebaran Robotics, which was acquired by Softbank in 2013 for $100M. More recently Maisonnier started Another Brain and raised EUR10M in February 2018. Maisonnier is an active investor. Serge Verdier is the current CFO/COO of SARIA Industries (France), a large foodstuff company part of the SARIA Bio-Industries AG & Co group of companies.

Besides the private funds raised in the last 5 years, Pollen AM has received significant French public money from grants. Michel told me that the company should be in a good position to raise institutional investment from large industrial groups in early 2019.

Pollen AM to equip one factory to produce spare parts by the end of 2018

The Palm P is now in full commercialisation at a starting price of circa EUR 20,000. The Palm series M will be released in the next 12 months.

Cedric was delighted to share with me the recent contract for the delivery of 10s of Palm P 3D Printer to a significant small appliances manufacturer to fully equip one factory to produce spare parts for dishwashers, vacuum cleaners and other small appliances. The delivery is expected by the end of the year. We will report further on this news in the next months.

Other customers include a sportswear manufacturer, and companies in the aerospace and medical sectors. During the next 6 months, Pollen AM will deliver a 10 Palm P 3D printers to Another Brain.

Featured image shows the Pollen AM Pam series M. Photo via Pollen AM.