For one of its latest set designs, the prestigious Teatro dell’Opera di Roma in Italy has enlisted the help of large-scale 3D printer manufacturer WASP.

The set has been made for a production of Daniel Auber’s 1830 opera Fra Diavolo (Brother Devil). A story of thwarted love and intrigue, scenes play out in front of an arrangement of warped buildings, similar to the melting, surrealist artworks of Salvador Dalí.

Recreating history

WASProject’s brief was to make two stage-sized facades of historic buildings complete with windows and terraces.

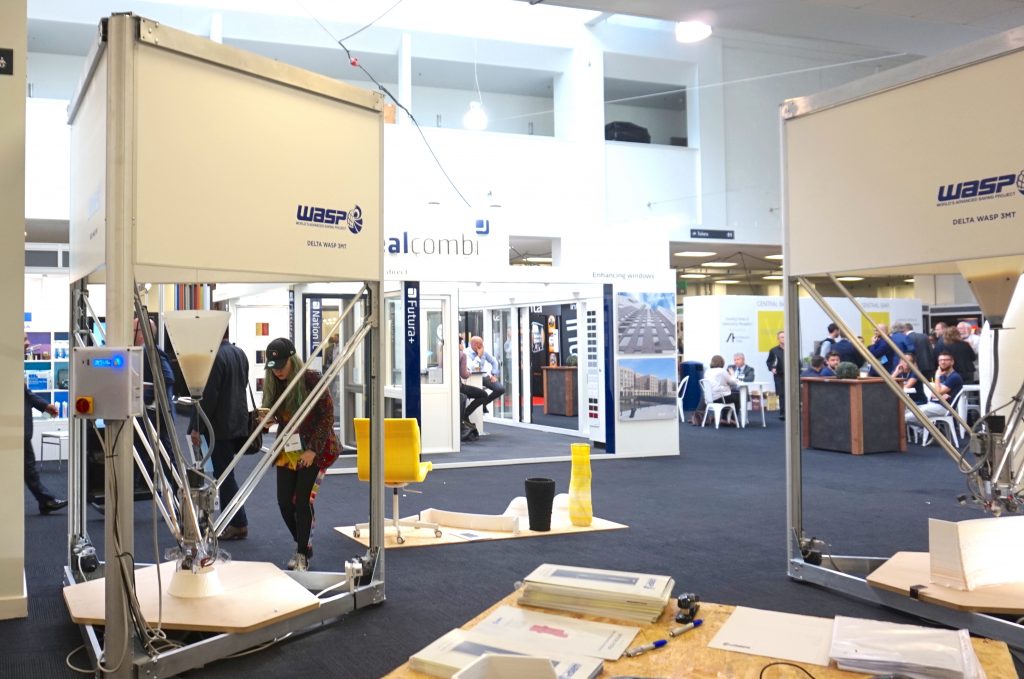

To facilitate transportation, storage, and assembly, the set had to have a modular design. This approach also meant that the facades could be 3D printed inside a DeltaWASP 3MT, which has a maximum build cylinder of 1 meter x 1 meter.

233 pieces of PLA

The two backdrops were initially CAD modeled by the team in full. The designers then determined how to cut each model so it could be 3D printed in stages.

In total it took 223 panels of PLA to make the two sets. These were 3D printed by WASP over the course of 3 months using a bank of five 3MT machines.

3D printing takes center stage

Though the WASP facades may be the first of their kind in the theatre, it certainly isn’t the first time that a 3D printer has featured in the limelight.

FDM technology has been used almost since its inception to make miniature scene settings for the Broadway stage, and Cirque du Soliel’s costume department recently installed a 3D printer on tour to make more robust props.

To learn more about the possibilities of 3D printing sign up to the most widely read newsletter in the industry here, follow us on Twitter and like us on Facebook.

Find conferences, seminars and workshops near you on our 3D printing events page.

Featured image: View inside the Teatro dell’Opera di Roma. Photo by Silvia Lelli