Titan Robotics, the company behind the 5-print-head Cronus 3D printer, has introduced a new Pellet Extrusion technology to take large format 3D printing to the next level.

The technology was showcased at this year’s RAPID + TCT 2018, installed inside a new line of 3D printers and used to print the hexagonal facias decorating the stage inside the keynote theater.

Going large

With typical filament feedstock, material capabilities are reserved only to polymers that have been and can be extruded from a wire. By using pellets instead, Titan Robotics taps into a mine of readily available materials that have been tried and tested by the injection molding industry.

This significantly expands the material possibilities of its FFF extrusion-based technology, covering everything from soft, rubberlike materials to high performance plastics, including 50% glass fiber reinforced nylon and 50% carbon fiber filled PEI.

Pelletized feedstock stock is also specially suited to large-scale applications. Italian 3D printer manufacturer WASP Project uses this type of material in its large-scale 3MT 3D printers, and Oak Ridge National Laboratory (ORNL) favors this material form for projects including the U.S. Navy’s 3D printed submarine and this Caterpillar Excavator.

Up to 5Gs acceleration

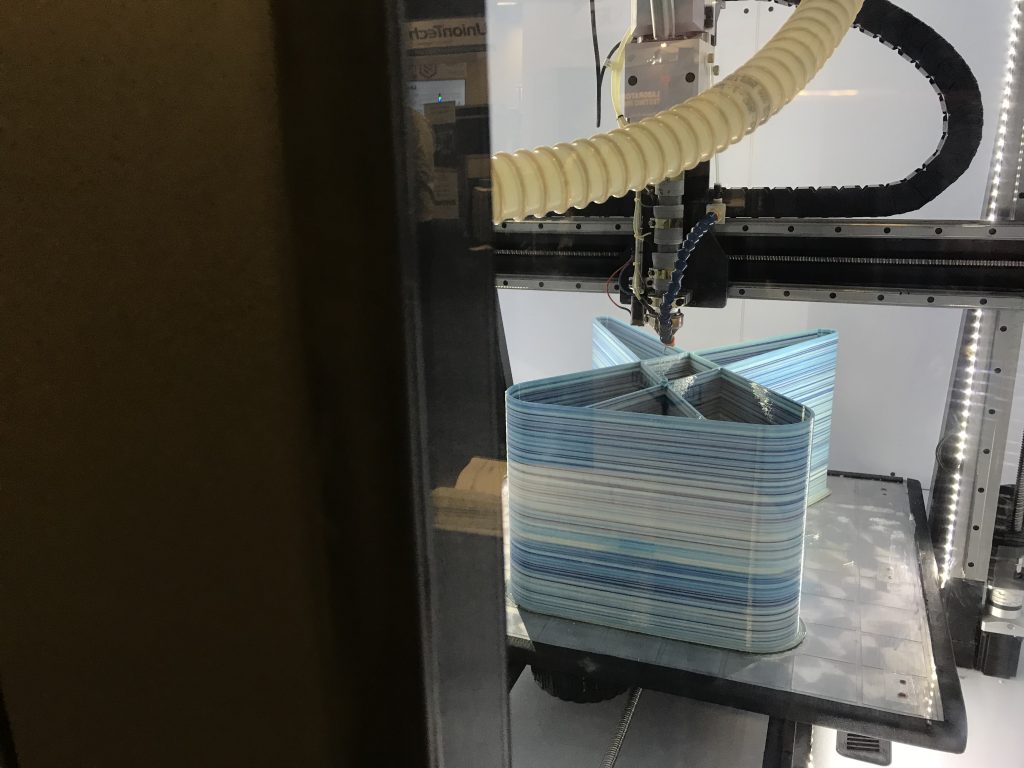

Direct pellet fed 3D printing is demonstrated by Titan Robotics in a custom model of its flagship Atlas 3D printer (not to be confused with GE’s ATLAS for powder bed fusion).

The pelletized Titan Robotics Atlas is installed with top of the line servo motors from motion control experts Yaskawa America, a subsidiary of Japanese robotics company Yaskawa Electric Corporation.

Through this collaboration, the Yaskawa Atlas is capable of printing at speeds up to 350 mm/s, reaching up to 5Gs of acceleration. Moving between prints inside an enclosed build chamber, the nozzle moves at a rate of one meter per second.

The 3D printer is also capable of real-time feedback and automatic monitoring to ensure print repeatability.

Wasting no time

Following the demo at RAPID + TCT, pellet upgrades are avaible for any exisiting Titan Atlas model through the company’s website. Clay Guillory, founder and CEO of Titan Robotics, comments, “We’re really focused on having an accurate, robust machine that can do big parts really quickly and reliably, over and over again,”

“Our customers want something they can trust…they can’t afford to waste two weeks of print time on a really large, mission critical part.”

For regular news updates sign up to the most widely read newsletter in the industry here, newsletter, follow 3D Printing Industry on Twitter, and like us on Facebook.

Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Vote for you innovations of the year in the 2018 3D Printing Industry Awards – the form closes next week.

Featured image shows Titan Robotics’ gantry in the Cronus 3D printer. Photo via Titan Robotics