Italian 3D printing company WASP, manufacturers of DeltaWASP 3D printers, have introduced two new industrial 3D printer models at the MECSPE B2B manufacturing conference in Parma. Both DeltaWASP 3MT and 4070 models add industrial improvements to the pelletized plastic feedstock of the company’s existing machines, enhancing the accuracy and reliability of small and large 3D prints.

The two machines come alongside three further releases from the company including an update to the DeltaWASP 2040 Turbo, designed for speed, and two new extruders for single and dual extrusion.

DeltaWASP 2040 Turbo2

According to WASP the DeltaWASP 2030 Turbo 2 is, “a revised and improved version of the standard DeltaWASP 2040 Turbo.” The 3D printer has a “new integrated 32bit board of industrial technology. It is presented with a supply system which can support 2 high power extruders. The new Turbo (Turbo 2) introduces a new carriage-sliding system improved in speed and accuracy. The room has been better insulated to reach temperature suitable with the printing of technical materials – furthermore it has a cool system for the engines and the boards and a kinematics for high temperature. It’s introduced with the second optional extruder.”

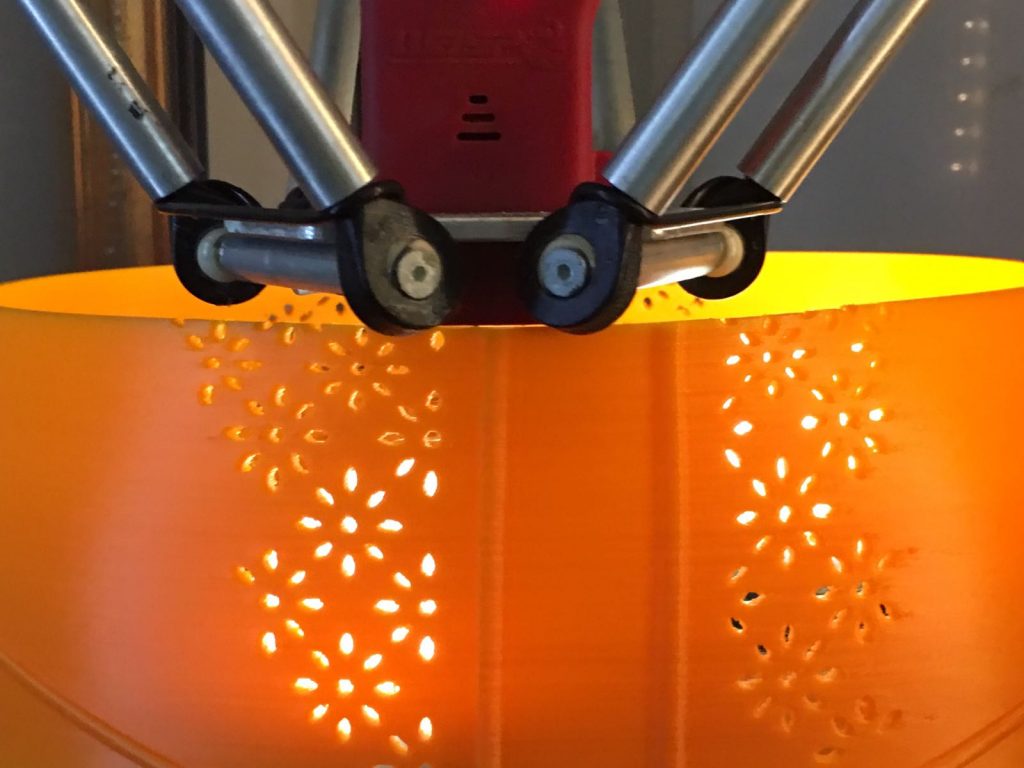

DeltaWASP 3MT & 4070 Industrial

In the industrial model the DeltaWASP 4070 has been revised to include a heated print chamber, and ventilation. The additions enable the machine to use materials only suitable for 3D printing in these environments including Nylon and ABS (over a certain height). Particular studies into the scalability of 3D printed ABS have been done by Oak Ridge National Laboratory, which also focused on pelletized feedstock as it gives different pore structure.

The DeltaWASP 3MT Industrial model has a fully enclosed acoustically and thermally insulated build chamber. This protects 3D prints from external vibrations that can cause imperfections. The extruder is interchangeable with nozzles of 0.4mm, 0.7mm, 1.2mm, and 3mm diameters.

Spitfire and Zen Extruders

The Spitfire is WASP’s new extruder that, depending on the 3D print settings, is “able to lay up to 30m wire per hour”.

The Zen Extruder is a dual-nozzle device developed by WASP for multi-material 3D printing. The Zen also has and built cleaning facility and a nozzle-variable-hight-system so layers of an object can be 3D printed at differing thicknesses.

Large scale 3D printing

In March 2017, WASP 3D printers were used to 3D print the organically inspired large scale Trabeculae Pavilion on display at the Milan MADE Expo.

Another company exploring the possibilities of large 3D prints include Tennessee-based Branch Technology, who used Oak Ridge National Laboratory developed Bamboo filament for the SHoP Architects Flotsam and Jetsam pavilion in Miami.

To stay up to date on large scale 3D printing releases, sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for the best industrial 3D printers now in the first annual 3D Printing Industry Awards.

Featured image shows DeltaWASP original 40 70 Pro models at the MADEexpo 2017. Photo via wasproject on Facebook