Industrial metal 3D printer manufacturers BeAM Machines, headquartered in Strasbourg, France, has delivered its 5 axis Magic 2.0 machine to it’s Solutions Center in North America. The facility in Cincinnati, OH, was reported as a “major milestone” for the company when it opened in February 2017.

At the time of launch, BeAM CEO Emeric d’Arcimoles commented,

Opening a U.S Subsidiary is a major milestone, given the prospects for robust and rapid growth harbored by the American market. BeAM intends to become a major player in the U.S., which has become the world leader in additive manufacturing.

Inside the Magic 2.0

The Magic 2.0 is BeAM’s multipurpose machine using Laser Metal Deposition (LMD) to additive manufacture, modify and repair technical components.

Demonstration of multi axis Laser Metal Deposition (LMD) inside a BeAM machine. Clip via BeAM Machines on YouTube

Tim Bell, General Manager of BeAM Machines North America, explains “Some of the more unique applications include combining multiple advanced technologies such as Powder Bed Fusion and Directed Energy Deposition”. Powder bed fusion is the laser powered additive manufacturing of choice inside the Magic 2.0. Directed Energy Deposition is the method of using this laser to repair and add to existing parts.

Bell continues,

leveraging the abilities of both of these additive manufacturing technologies at the component design level, [allows] some of the world’s most advanced manufacturing facilities to push the envelope on what is possible. The freedom of design that Additive Manufacturing gives our customers allows them to achieve component performance and life cycle levels that historically were only ‘pipe dreams’.

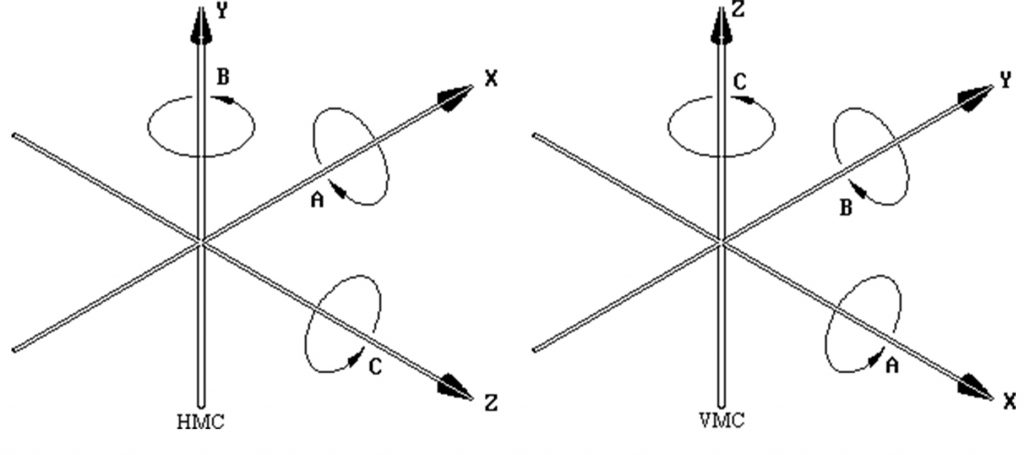

The Magic 2.0 machine is capable of working on anything from three (the standard X Y Z) to five axis (X Y Z + B C), meaning that parts can be engineered for use from all angles.

Metal 3D printing and fixing for turbine blades in aerospace and energy

According to the company, “The Magic 2.0 is often used by Aerospace MRO sites to repair gas turbine engine shaft seals, stator vanes, LPT Blades,” (found in turbines) “as well as other high value components that are historically unrepairable.”

Founded in 2012, BeAM’s industrial partners have grown to include France’s Fives Machining Systems, Inc., a subsidiary of industrial engineering group Fives; and aerospace component manufacturers Safran Power Units (EPA:SAF).

In 2016, a collaboration between Safran, Amaero Engineering and Monash University in Australia, presented a 3D printed mock up of a jet engine at the Melbourne International Airshow 2016.

At Formnext 2016 BeAM CEO Emeric d’Arcimoles gave us his perspective on how the company will innovate to stay ahead, rather than using patents to shut out competition.

To stay up to date with the latest industrial additive manufacturing news, sign up to the 3D Printing Industry newsletter and follow our active social media sites.

Readers can now vote for the enterprise 3D printer of the year in the first annual 3D Printing Industry Awards.

Featured image shows the Magic 2.0 5 axis machine. Photos via BeAM Machines