Italy’s largest technical university, Politecnico di Milano, will present a large-scale 3D printed arch at the MADE expo 2017. The Trabeculae Pavilion has been created by the university’s Architecture Computation Technology Lab (ACTLAB) to show the fluid possibilities of computer aided design (CAD) and 3D printing.

Architecture mimics nature

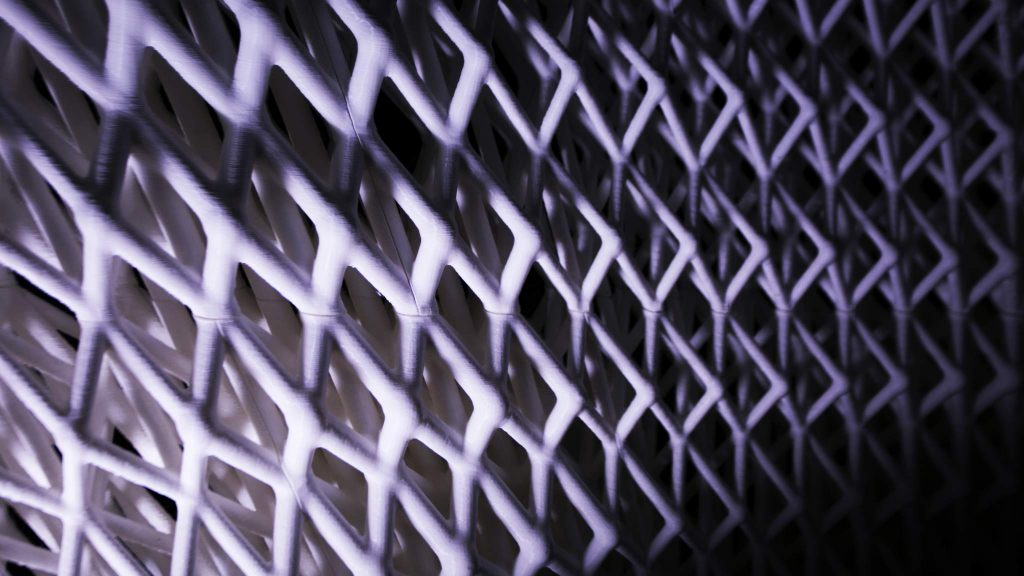

In anatomy, trabeculae is the name given to the connective bands of tissue inside cancellous, or spongy, bone. ACTLAB co-founders Roberto Naboni and Professor Ingrid Paoletti explain,

We looked into Nature to understand how lightweight and resistance structures work with a minimized material use. Studying the internal bone micro-structure, we have created algorithms which allow us to generate three dimensional cellular structures, varying in topology and sizing, with the precision of a tenth of a millimeter.

The organic design has also been replicated in the filament used to make the pavilion. 3D printer materials manufacturer Filoalfa, also based in Milan, collaborated with ACTLAB to create a high-resistance biopolymer for the structure. Naboni and Professor Paoletti add,

The last decades have witnessed an exponential growth in the demand of raw materials due to the rapid industrialization of emerging economies and the high consumption of materials […] Our objective is to explore a new type of non-standard architecture: advanced, efficient and sustainable.

A bank of DeltaWASP FFF 3D printers, from Northern Italy’s WASP (World’s Advanced Saving Project), were used to 3D print the Trabeculae Pavilion in segments.

Rebuilding the world with 3D printing

New York’s SHoP Architects also created a biologically inspired pavilion, tipped to be the largest 3D printed structure in the world, for the Design Miami exhibition in 2016-2017. The Flotsam & Jetsam structure was created with the help of 3D printed construction experts Branch Technology, using a bamboo-based filament from Oak Ridge National Laboratory (ORNL).

The freedom of 3D printable design combined with greener materials is poised to change how people live. ACTLAB’s founding principle is “exploring the intersection of architecture with computational techniques, advanced manufacturing and innovative materials.”

The Institute for Advanced Architecture of Catalonia (IAAC) in Spain, whose designers caused a stir in December 2016 with their 3D printed reinforced concrete bridge, share similar principles to Milan’s ACTLAB. The IAAC are “Shaping the future of cities, architecture and technology”, and are at the center of the global Fab City movement. The concept of a Fab City is to create a more sustainable production cycle, and encourage localised manufacturing by connecting communities around the world.

To stay up to date on 3D printing in architecture, sign up to the 3D Printing Industry newsletter, and follow our active social media profiles. Let us know your thoughts on the technology in the comments below too.

Featured image shows the Trabeculae Pavilion 3D printed by ACTLAB in collaboration with Filoalfa. All photos featured in this article are courtesy of ACTLAB at Politecnico di Milano.