Market leading 3D printer manufacturer 3D Systems has announced the launch of 3DXpert for SOLIDWORKS, a 3D print preparation software package that optimizes 3D designs for additive manufacturing.

3DXpert, which was shortlisted for the 3D Printing Industry Awards Software of the Year Awards 2017 alongside SOLIDWORKS, is available exclusively to SOLIDWORKS customers as part of their annual subscription.

Unlike the software already offered alongside 3D Systems metal 3D printers, the upgraded 3DXpert software includes a new range of tools to create a direct path from SOLIDWORKS designs to both metal and plastic additive manufacturing.

Helping designers fulfill technological potential

Despite the importance of more of the workforce reorienting their existing skills in light of the growth of additive manufacturing, 3D Systems suggests that the difficulty of this is preventing some designers taking full advantage of 3D printing technologies.

With the new 3DXpert software, SOLIDWORKS users will have the design freedom to deliver complex geometries, light-weight parts without compromising strength, and to apply surface textures that deliver functional or aesthetic benefits.

“We’ve seen a tremendous increase in the adoption of additive manufacturing,” said Gian Paolo Bassi, SOLIDWORKS CEO. “As a result, we collaborated with 3D Systems to provide SOLIDWORKS users with the tools to help them design specifically for additive manufacturing, which requires a different set of operations and rules than more traditional, subtractive manufacturing.”

The key features of 3DXpert for SOLIDWORKS

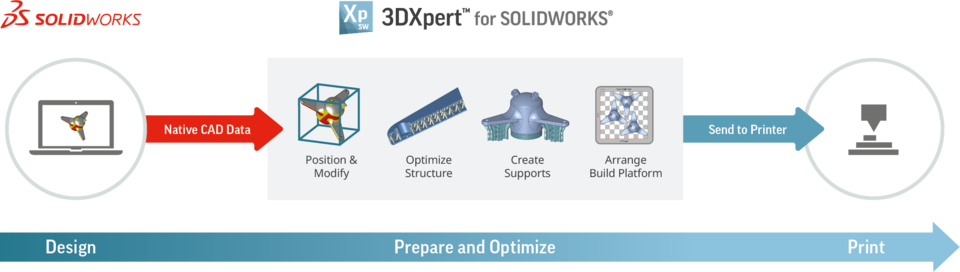

As part of the design workflow in 3DXpert for SOLIDWORKS, designers can import native CAD data without the need to convert it to STL, and maintain the integrity of the original design until 3D printing it.

Another important feature is the ability to optimize the object structure. This can be done through freely altering lattice structures or infill designs, modifying surface texture, and implementing automatic adjustments based on 3DXpert’s FEA linear-stress analysis.

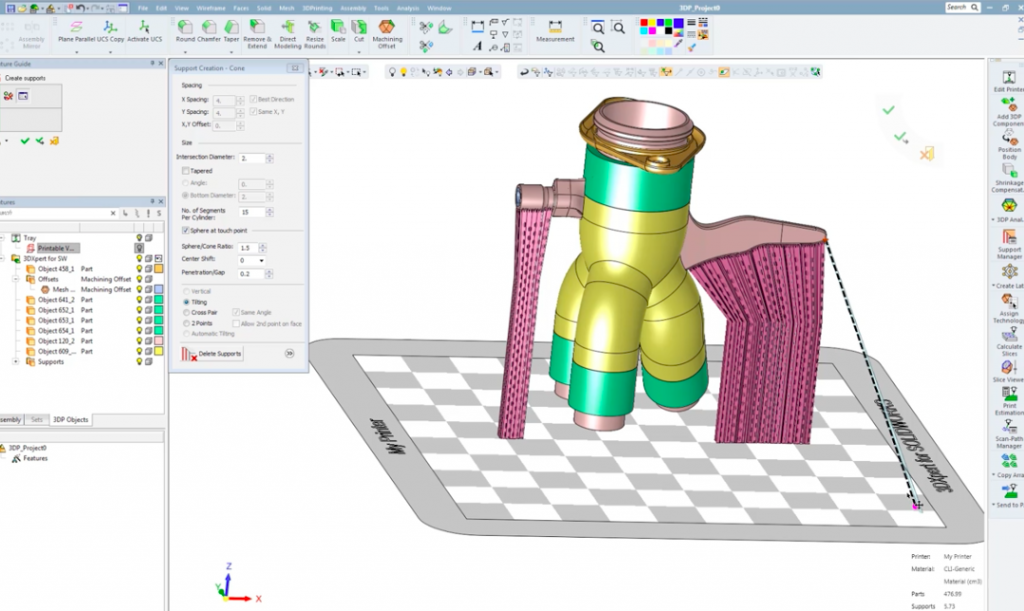

Similarly, support structures can be designed to simultaneously deliver quality prints and save material by minimizing supports. In 3DXpert for SOLIDWORKS, automatic analysis inserts supports where they are needed, but these can also be tilted, scaled, or reconfigured to facilitate their removal.

Preparation time well spent

Finally, print preparation time is streamlined with automatic features such as tray setup, estimations of material usage, and calculations of build time.

Hybrid CAD tools, automatic best fit options, build plate positioning, and multiple format export options also ensure minimal divergence from the CAD design and the 3D printed result. 3D Systems CEO Vyomesh Joshi commented that:

“This collaboration enables SOLIDWORKS users to create more shapes, more ways, and accelerate product development cycles while lowering costs.”

“We are offering designers a true competitive advantage while re-defining the design and manufacturing process,” Joshi added.

Let us know what you think the best 3D software company has been this year. Make your nominations for the 3D Printing Industry Awards 2018 now.

For more stories on 3D software and print preparation, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the 3DXpert for SOLIDWORKS icon. Image via 3D Systems.