This week’s edition of Sliced, the 3D Printing Industry news digest, answers: How is 3D printing helping to break the land speed record? Can bioprinters be used in rugged military environments? What is the largest 3D printed building in the world? And how can you create your own robot vacuum cleaner?

Read on for the latest business developments and partnerships from the world of additive manufacturing, as well as news about 3D printing from automotive, aerospace, medical and more. You’ll find a host of updates from the likes of 3D Criar, Nano Dimension, Dassault Systèmes, Protolabs, Lockheed Martin and Prusa Research, to name a few.

Protolabs expands European HQ

The first in a series of business developments this week, 3D Criar, a Brazillian 3D printer reseller, has initiated a series of strategic actions to consolidate its leadership and expand its growth over the next two years. Since the first quarter of 2019, the company has been focusing on increasing its presence in the market by incorporating subsidiary 3DC Med into the main company umbrella, as well as hiring a new CEO to manage the entire operation.

“We seek to innovate and bring the latest to the Brazilian market, always through a lot of research, development and relationships with major players in the world,” explains Daniel Huamani, CTO of 3DC Med. “In order to orchestrate the new structure, we had the help of an external consultancy, providing security and the solid basis to reach the estimated growth to consolidate our leadership in 3D printing in the Brazilian market.”

Blueprint, a Stratasys-owned additive manufacturing consultancy, has launched the technology enablement program “Think Additively” to help businesses adopt 3D printing.

Nanofabrica, a Tel Aviv-based developer of precision additive manufacturing technologies, has joined the #STARTUPNATION to Mittelstand (#SNTM) programme, a venture capital and private equity outfit based in Cologne, Germany seeking Israeli Industry 4.0 start-ups.

Australian 3D printing reseller EVOK3D has completed a partnership equity agreement with Currie Group, an end-to-end service supplier to the Graphic Arts industry in Australia and New Zealand. Working together, the new partnership is intended to accelerate the growth in EVOK3D’s sales whilst leveraging Currie Group’s management experience and Australian and New Zealand footprint.

Israeli 3D printed electronics company Nano Dimension has announced that it has sold over 50 of its DragonFly electronics additive manufacturing systems worldwide. The milestone is based on figures collected since the launch of its commercial sales in late 2017. “We are excited to announce the sale of our 50th DragonFly system for additive manufacturing of electronics,” commented Amit Dror, CEO of Nano Dimension.

“Nano Dimension started with a breakthrough idea to change the way the electronics are made and to offer new solutions to develop innovative smart products.”

On-demand digital manufacturing provider Protolabs has announced a £5m ($6.4m) expansion for its European headquarters in Telford, UK. Using the investment, the company plans to build a 50,000 sq. ft. extension to the facility, housing additional manufacturing systems and creating 60 new jobs over the next 2 years. The expansion is intended to help the company meet growing demand from clients across the automotive, aerospace, medical, electronics and heavy industry sectors. Recently, the company launched a new polypropylene 3D printing service for its customers in Europe.

Product releases in 3D printing

Numerous releases spanning 3D printers, materials and post-processing solutions have taken place this week. Global chemical manufacturer Huntsman, for example, has showcased its new range of additive manufacturing materials at K 2019 trade fair for rubbers and plastics in Messe Düsseldorf, Germany. The IROPRINT was first introduced in four months ago and includes powders, resins and filaments.

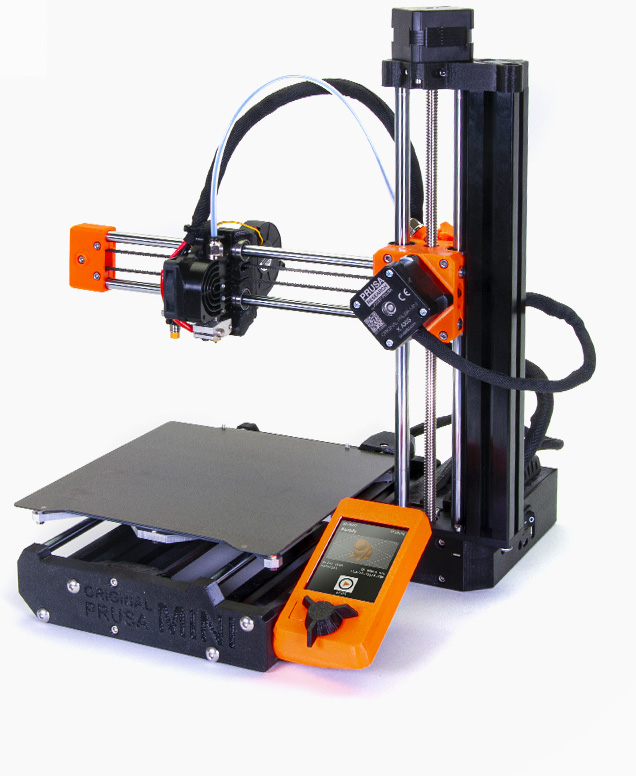

Czech open source 3D printer manufacturer Prusa Research has introduced a new system, named the Original Prusa MINI. It is the company’s smallest machine, equipped with a build volume of 18 x 18 x 18 cm. Prusa has stated that it is also working on a larger system with a 40 x 40 x 40 cm build, called the Prusa XL.

German additive post-processing specialist Solukon and Siemens have partnered for the development of an automated system for highly efficient De-Powdering of challenging laser melted metal parts known as SFM-AT800-S. This machine integrates Siemens`s intelligent algorithm which rotates a part in a sequence calculated from the CAD geometry to drain the residual powder from intricate cavities such as conformal cooling channels.

3D printing cloud platform AstroPrint is launching a bespoke version of it’s Management Platform for Universities, K-12 schools and educational institutions. Register for Beta Testing of AstroPrint for Education here.

Building the generation airplanes and helicopters

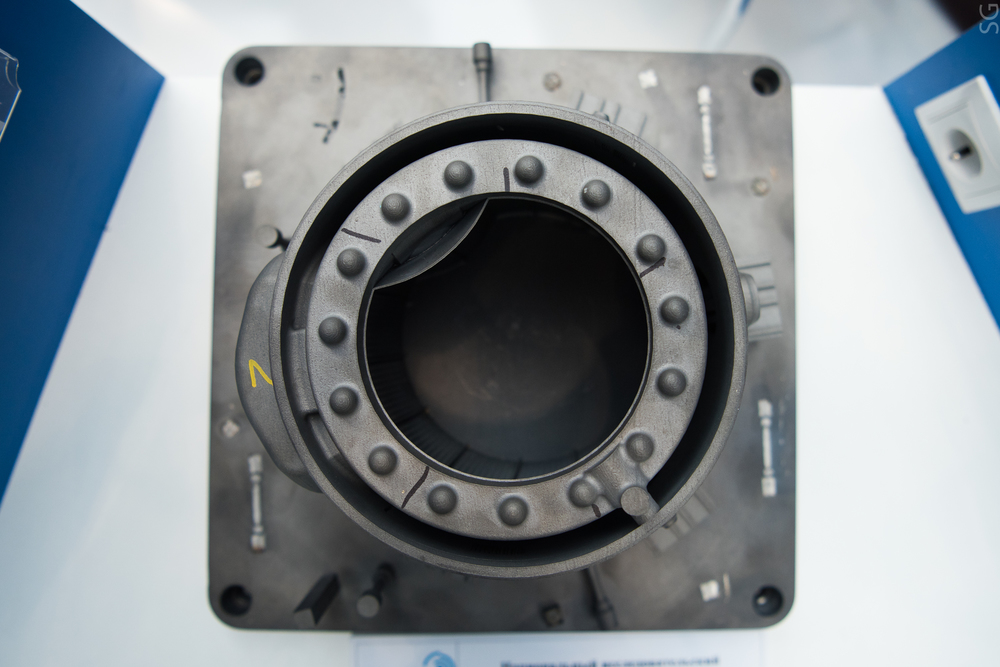

Moving on to aerospace, Engineers from St Petersburg Marine Technical University (SMTU) and the National University of Science and Technology (MISiS) have created the first full-size prototype 3D printed helicopter engine case using Selective Laser Melting (SLM). The 3D printed domestic aircraft engine PD-14 was produced using titanium alloy power in 14 days and reduced the weight from the original by over 75%. It was presented at the MAKS International Aviation and Space Salon, Moscow, in September.

Global aerospace and defense company Lockheed Martin has selected Dassault Systèmes‘ 3DEXPERIENCE platform to support its ‘Digital Engineering’ initiatives. Using the platform for the next few years as an engineering and manufacturing planning toolset, Lockheed Martin aims to speed timelines and improve efficiencies of next generation airplanes and helicopters.

“The 3DEXPERIENCE platform will facilitate Lockheed Martin’s digital engineering goals and help optimise their product engineering with an integrated platform approach,” stated David Ziegler, Vice President, Aerospace & Defense Industry, Dassault Systèmes. “This approach lends flexibility to extremely complex programs and drives the advances in sophisticated aircraft innovation that are defining the 21st century of the aerospace industry.”

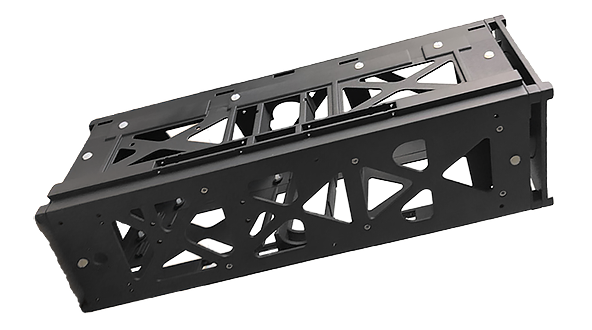

Italian materials manufacturer CRP Technology has collaborated with students at the Laboratoire InterUniversitaire des Système Atmosphérique (LISA) of Universite Paris-est Creteil (UPEC). Together, they 3D printed a 3U CubeSat using CRP’s Windform TOP-LINE family of high performance materials. The project manager at LISA, commented, “Using such a process and composite material from Windform’s TOP-LINE, we knew for sure we would be able to design the structure exactly the way we needed it.”

CRP also attended the Composites in Motorsport conference, which took place from 22 to 23 October at the Williams F1 Conference Centre, Oxford, UK. Performing as a speaker, CRP delivered a presentation entitled: “How Additive Manufacturing composite materials drive EV Motorsports”.

Breaking the sound barrier with 3D printing

3D printing in automotive this week has seen LÄPPLE Group, a German automotive solutions provider, reduce its lead times and costs by 50% compared to its traditional manufacturing methods for specific production appliances using the MakerBot METHOD and Replicator Z18. The company also eliminated the need for off-tool sheet metal parts in fixture manufacturing using the in-house 3D printers.

Briggs Automotive Company (BAC) has used the RPS NEO 800 from 3D printing service provider Malcolm Nicholls Ltd (MNL) to produce prototypes for the BAC Mono R supercar.

E-mobility startup Uniti Sweden has revealed the pricing and specifications for its debut electric vehicle (EV), the Uniti One. It will be priced from 15,100 in the UK, with a range of up to 300km. Intended for urban city transport, the Uniti One has been designed in response to today’s changing transportation needs. Last year, Uniti had announced plans to launch a pilot production plant for its electric vehicles (EVs) in the UK incorporating 3D printing technologies.

After being shipped to South Africa earlier this month to begin its trials, the Bloodhound supersonic car has now completed its first initial test drive across the Hakskeen lakebed. The vehicle, which features 3D printed parts, was relaunched in March 2019 after development halted in October 2018 when the project failed to secure investment. The first test drive was completed at a slow 100 mph, with plans to run at incrementally faster speeds in the coming days. The goal is to reach 500-600mph (800-965km/h), a key milestone in the Bloodhound team’s bid to set a new world land speed record by eventually reaching 1000 mph.

Building additive manufacturing centers

Various 3D printing facilities have been implemented across the world recently. For example, Australian med-tech company Anatomics has launched a new 3D printing lab in East Bentleigh, Melbourn, to create 3D printed implant material that can augment bone and integrate into human tissue. The facility was opened by Gregory Hunt, Austrialian Health Minister, on October 10th.

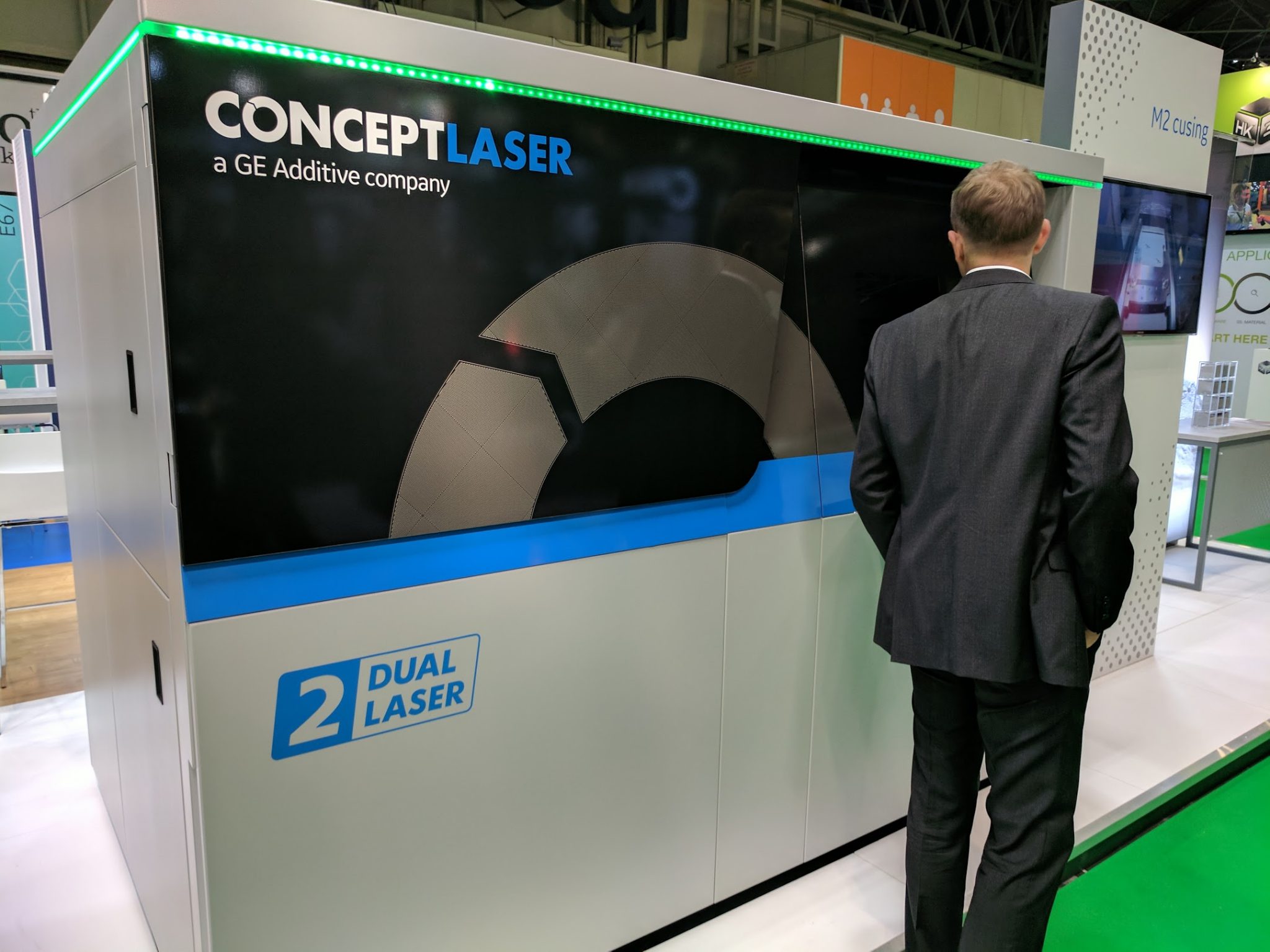

In Saint John, Canada, a Marine Additive Manufacturing Centre of Excellence (MAMCE) has been established which is equipped with a GE Concept Laser M2 3D printer. The MAMCE involves Custom Fabricators and Machinists (CFM), the University of New Brunswick (UNB), and the New Brunswick Innovation Foundation (NBIF).

The University of Central Lancashire (UCLan) has launched a new £35m ($45.1m) Engineering Innovation Center equipped with an additive manufacturing lab and workshop. It is intended to engage directly with industry and provide students with real-world experience on live, engineering-related projects. Other facilities include an intelligent systems facility, a motorsports and air vehicles lab, a high-performance computing lab, a flight simulator suite as well as a fire, oil and gas facility.

Simulating bone surgeries

A MakerLab at the Gies College of Business, University of Illinois at Urbana–Champaign (UIUC), has partnered with Thera-Solutions, Medical Device company, to develop a universal cuff that allows the user to hold tools of many shapes and sizes. Known as the Functionalhand, the 3D printed tool is designed to aid children and senior citizens lacking mobility in their hand.

The Geneva Foundation and the Uniformed Services University (USU) recently completed a successful pilot project for its 4D Bio3 program, which aims to develop advanced bioprinting, biofabrication, and biomanufacturing technologies for research beneficial to Department of Defense (DoD) priorities. It was carried out in collaboration with nScrypt, a Florida-based manufacturer of micro-dispensing and 3D printing equipment, and bioprinting firm RoosterBio, Inc. The pilot project involved the biofabrication of medical products in an austere military environment, using a customized version of nScrypt’s BioFabrication Facility bioprinter, called the Austere BioAssembly Tool (ABAT).

An art and design researcher from the University of New South Wales (UNSW) in Sydney is using 3D printing to help accurately simulate children’s bones for surgeons. Dr Kate Dunn’s research has focused on the development of new technologies like robotics, 3D printing and laser cutting over the last few years. This has now lead her to a new position in the Faculty of Built Environment at UNSW. There she will work alongside researchers on a bone simulation project using 3D printing for Westmead Children’s Hospital.

3D printing in design and construction

Portuguese 3D printing service provider Diverte has designed a large 3D printed art installation serving as part of the cultural program of Estação Viana Shopping, ‘Pulsar Viana.’ Named ‘Amore Minhoto’, it can be viewed at the mall through October 30th.

GROHE, a sanitary fittings manufacturer, is set to showcase its collection of metal 3D printed taps known as ICON 3D at the Sleep & Eat 2019 exhibition, which takes place from 19 to 20 November in London. The range, consisting of the company’s Allure Brilliant Icon 3D and Atrio Icon 3D taps, features geometrically complex designs created using powder bed laser melting technology. The company first announced it was introducing 3D printing to its manufacturing process in early 2018.

Dubai has unveiled a new 3D printed building which now holds the Guinness World Record for the largest on-site 3D printed construction. Developed by 3D printing construction firm Apis Cor, in collaboration with the University of Nantes, the two-storey building stands at 9.5 metres tall with a total area of 640 square metres. It was built in Warsan, and has undergone a year of testing, meeting all the required building standards. This is the latest in a series of developments for 3D printing construction in the country, in a bid to realize Dubai’s vision for 2025 where at least 25% of every new building in the city will be 3D printed.

“This project is a major turning point in the construction sector,” commented Dawoud Al Hajri, Dubai Municipality director general.

“3D printing technologies in construction will increase the speed of execution and [lead to the] completion of buildings in record time.”

Interesting 3D printing applications

The National Football League (NFL) is running an NFL Helmet Challenge in collaboration with Ohio-based national accelerator for additive manufacturing America Makes. The challenge will award up to $2 million in grants to experts, innovators and helmet manufacturers to develop a prototype for a 3D printed NFL helmet, as well as a $1 million award. A symposium will be held November 13-15 in Youngstown, Ohio, to kick off the challenge. The deadline for submissions is set for May 2021.

“Helmet technology is advancing at an impressive rate. Yet, we believe that even more is possible. The NFL Helmet Challenge represents an unprecedented combination of financing, research, data and engineering expertise in an effort to create a more protective helmet,” explains Jeff Miller, the NFL’s Executive Vice President for Health and Safety Innovation.

Another 3D printing application this week comes from Twan, otherwise known as “Theking3737”, the designer behind the Open Source Robot Vacuum Cleaner. Twan has released its successor, the Mark II. The Vacuum, which was made as part of a school project, was altered due to complaints about its excessive size.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo edited on photo of the Bloodhound supersonic car. Original photo via Bloodhound LSR.