WAAM3D Ltd, a spin-out company from Cranfield University, UK, has received funding from Accuron Technologies Ltd, an international engineering and technology group headquartered in Singapore. The investment completes a Series A round for WAAM3D.

Currently, the company is seeking to commercialize Wire-based Additive Manufacturing (WAAM) technology. With the new investment, WAAM3D will continue down this line of work, furthering development of the process for commercial applications. Professor Sir Peter Gregson, Vice-Chancellor of Cranfield University, stated: “Cranfield University fosters innovation and has a clear focus on applied research which impacts industry today and in the future.”

“I’m delighted to see this new technology take a big step forward and welcome Accuron Technologies’ support and investment.”

Investing in WAAM

Founded in 2018, WAAM3D was established for the purpose of commercializing all the elements needed for applying WAAM technology within engineering industries. This encompasses specialist CAM software, machinery, and materials, as well as support and training platforms to secure adoption and the technology’s usage throughout an organization.

The company is a spin-out of Cranfield University’s WAAMMat program, an initiative that aims to increase the maturity of the WAAM process in collaboration with industry partners. Since 2006, Cranfield University has been working on research and development surrounding the WAAM process. As well as the development of WAAM, the University will continue focusing its research efforts on new processes such as NEWAM (New Wire Additive Manufacturing) via industrial projects and grants from the Engineering and Physical Sciences Research Council. With the funding from Accuron Technologies, WAAM3D aims to bring in as many as 20 staff in the coming year to scale up operations and will continue to keep close ties with Cranfield University.

Accuron Technologies’ main activities surround precision manufacturing, material processing, systems design and system integration for the aerospace, electronics and medical industries. The company is a wholly-owned subsidiary of Temasek Holdings, a sovereign wealth fund owned by the Government of Singapore, which recently joined Carbon’s latest funding round as well. This represents a continued investment from Singapore into additive manufacturing technologies, as the country pursues further adoption of the technology for industries such as aerospace and maritime through various government schemes.

Tan Kai Hoe, President, and CEO of Accuron Technologies explains: “We are really excited about this opportunity to invest into WAAM3D. We have been looking at several additive manufacturing technologies for a while, and we think WAAM3D’s process has a real chance to transform manufacturing.

“We are very impressed with the company’s technology and expertise, which allows it to make large, high-quality parts for real-world applications. With our capital investment and industrial knowledge, we hope to help the company realise its true potential.”

What is the WAAM 3D printing process?

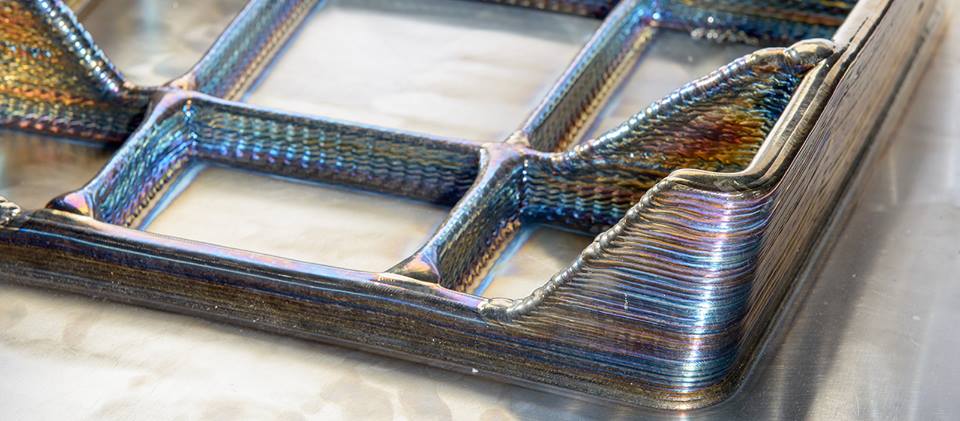

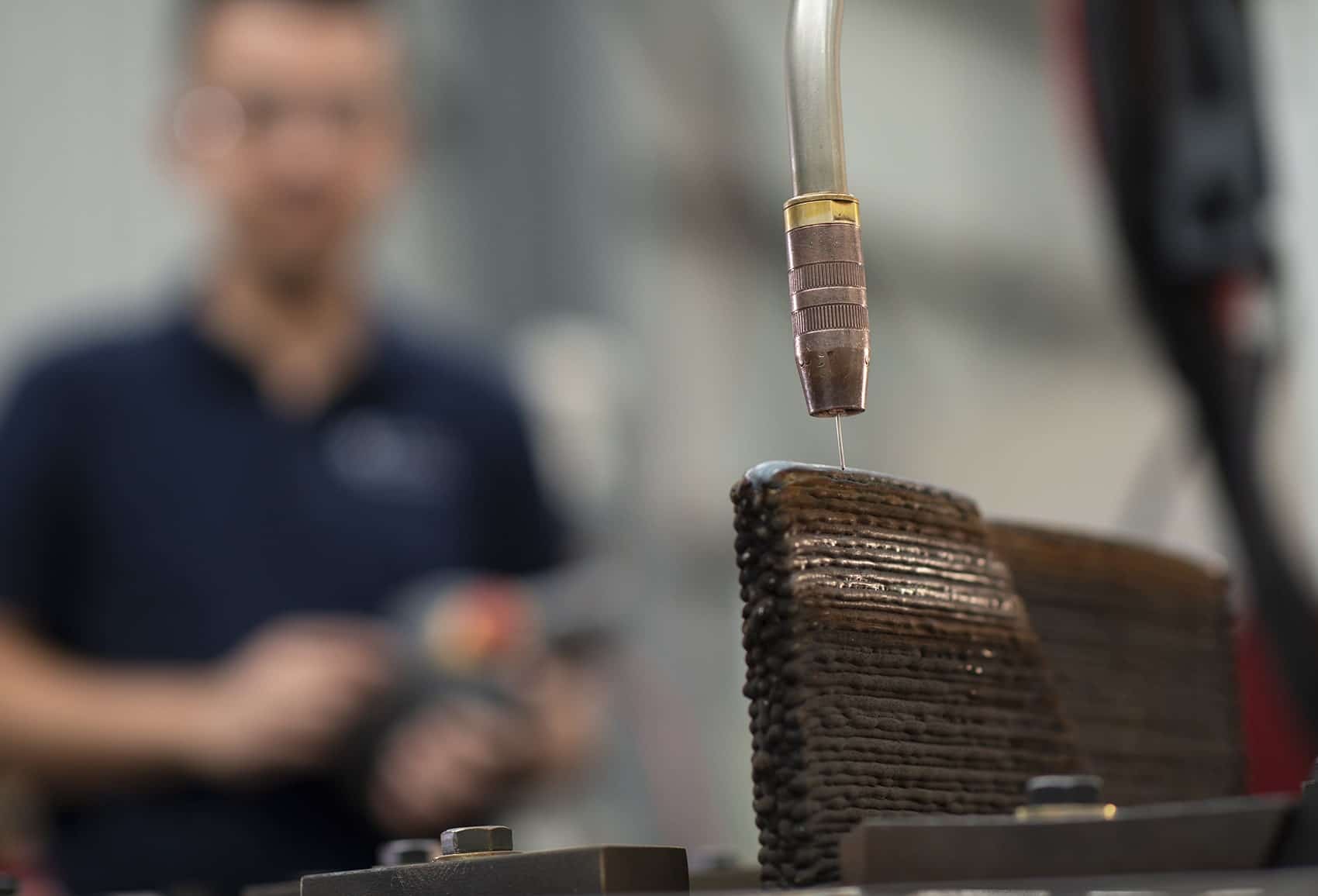

WAAM is a large-scale metal additive manufacturing process that uses an electric arc or laser to melt a metal wire feedstock in successive layers, subsequently forming the component. In 2014, WAAMat’s development work was showcased in the production of an impressive 1.2 meter long spare part. Between then and 2019, work on the project remained largely undisclosed, apart from a relocation within Cranfield’s £35 million Aerospace Integration Research Centre (AIRC).

However, last year, WAAM3D and Cranfield University unveiled two of the most high profile parts they have ever developed using wire arc additive manufacturing (WAAM) technology. These included a 2.5m x 1.5 m rear frame for a BAE Systems Eurofighter Typhoon aircraft, and a prototype pressure vessel developed in collaboration with a Franco-Italian aerospace manufacturer Thales Alenia Space. WAAM3D CEO Dr. Filomeno Martina, who is also a Senior Lecturer at Cranfield, described the two newly presented parts as the “most important results” of the WAAMat program. “All these parts have been programmed and built with a new CAM software developed by ourselves,” he added. Cranfield University and WAAM3D were also awarded Aerospace or Automotive Application of the Year at the 2019 3D Printing Industry Awards for the rear frame part.

Although Cranfield University has been a key driver for the development of WAAM in the industry through WAAMat and the formation of WAAM3D, there are a number of other projects and companies around the world that have developed their own WAAM methods. For example, RAMLAB at Rotterdam’s Innovation Dock is well known for its WAAM process, used to make the famous Damen Shipyards WAAMpeller. Robotic Additive Manufacturing (RAM) technology developer MX3D also leverages a process that combines ABB robotic arms and WAAM technology for its large-scale construction projects, including a 3D printed bridge across a canal in Amsterdam.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows WAAM at Cranfield University. Photo via WAAMMat.