Cranfield University, located in Bedfordshire, UK, has just opened a £35 million Aerospace Integration Research Centre (AIRC) center to boost the UK’s growing flight design and engineering ecosystem.

The facility features an unmanned aerial vehicle (UAV) laboratory; a virtual wind tunnel; a Fanuc robotic arm and more tools, including confirmed work by the university’s large-scale metal Wire-Arc Additive Manufacturing (WAAM) group. Airbus and Rolls-Royce have also been named as two of the facility’s official industry partners.

A brief history of WAAM

WAAM technology was developed at Cranfield in partnership with UK based defence contractor BAE Systems. In 2014, the university demonstrated WAAM’s ability to 3D print at scale in the creation of a 1.2 meter long spar part for an airplane wing. Made in a single operation, the titanium prototype took 37 hours to complete and presented an exciting potential for the future of the industry.

Speaking at the time of creation, WAAM project lead Professor Stewart Williams commented, “This is an exciting technology with huge potential for the aerospace industry. Cranfield is renowned for its close working relationships with industry partners and this is an excellent example. We will continue working with BAE Systems to improve the process and develop additional parts and processes that can be applied commercially.”

A further demonstration of WAAM was presented at the AIRC opening ceremony.

Additive manufacturing the Wing of Tomorrow

Trevor Higgs, the UK representative of official Cranfield partner Airbus, expressed optimism for the AIRC’s contribution to the radical redesign and manufacture of aircraft wings. Higgs commnets, “We at Airbus see the AIRC as a key part of the growing research ecosystem the aerospace industry has in the UK,”

“[The AIRC] will help us foster closer relationships with research partners and to accelerate and deliver on our research strategy for the Wing of Tomorrow, to make sure our products remain the best in world.”

The AIRC is in fact pre-installed with a full-size wing from an Airbus plane, located inside a 1500m2 open space work area. Since 2014, Airbus has also been leading a £16 million Agile Wing Integration (AWI) project in collaboration with Cranfield and two other UK universities. According to a description of the project on Cranfield’s website “It is hoped our work will improve efficiency by reducing the weight of the wings by up to 20%, as opposed to mere fractions, as well as helping to reduce manufacturing costs in the future.”

Airbus has also integrated a number of 3D printed metal parts into future and in-service aircrafts.

New era jet engines

For Rolls-Royce’s role in the project Henner Wapenhans, director of technology strategy, comments, “We are delighted to be a lead partner with Airbus in the Aerospace Integration Research Centre, which will also strengthen the existing strategic partnership between Rolls-Royce and Cranfield University,”

“This new centre will help develop the next generation of highly skilled engineers and will play an important role in developing the innovative technologies needed to enhance performance, improve efficiency and reduce emissions of future aircraft.”

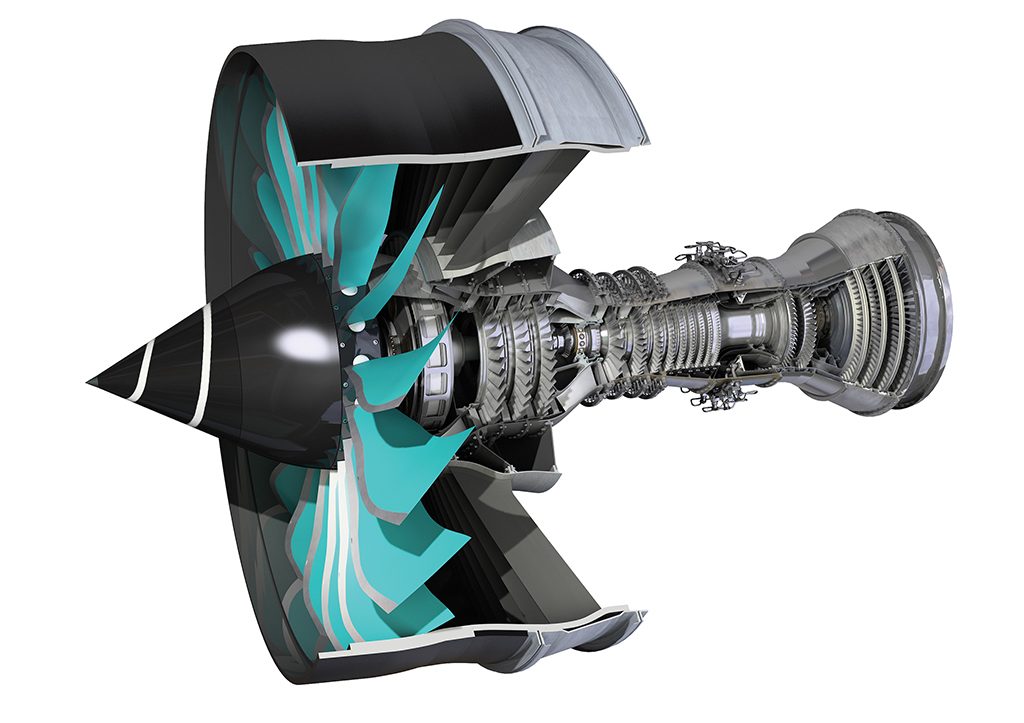

One of Rolls-Royce’s current innovations in civil aviation includes the creation of the most powerful aerospace gearbox, dubbed “The Power Gearbox,” and Advance3 new era 3-shaft jet engines combining a “new core architecture with a lightweight, low-pressure (LP) system, our composite fan, lean burn combustion and a raft of innovative manufacturing and materials technologies including 3D printing and CMCs.”

Professor Sir Peter Gregson, vice-chancellor and chief executive at Cranfield University, concludes, “Facilities such as the AIRC mean Cranfield is at the forefront of changing the way the world thinks about flight.”

“Greater integration between research and world-renowned businesses provides us with the opportunity to tackle some of aerospace’s grand challenges by providing the technologies, facilities and skills that are needed to succeed.”

For more of the latest 3D printing in aerospace news and more subscribe to our regular newsletter, follow on Twitter and like on Facebook. Register for 3D printing in engineering jobs here.

Featured image shows Cranfield University’s new Aerospace Integration Research Centre (AIRC) in the sun. Photo via Cranfield University