Silent air vehicles for transport and defense have been identified as an area of national need in the U.S. in a bid to cut noise pollution and enhance military intelligence. In the wild, owls are perhaps one of the best examples of natural stealth and aerial agility, giving researchers a promising area for potential development.

Inspired by the wing structure of the common barn owl, Professor Anupam Sharma, the Walter W. Wilson Faculty Fellow of Aerospace Engineering at Iowa State University, is leading a project to impact the design of next generation airplanes and wind turbines, with the help of 3D printing.

Implementing the “owl hush kit”

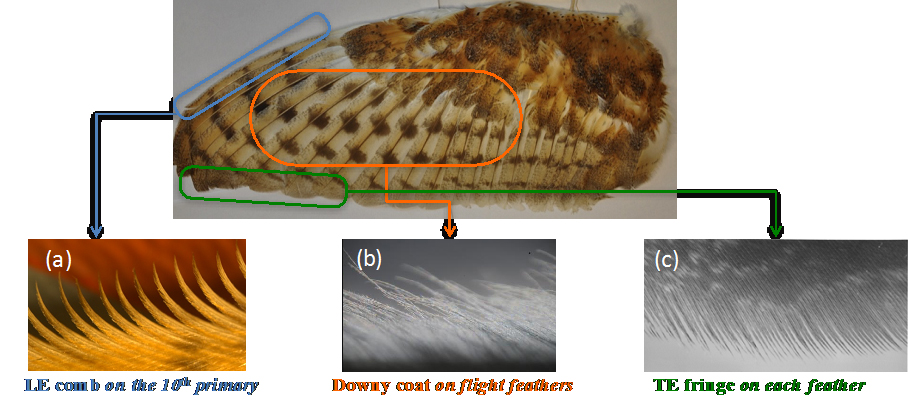

The phenomena of a barn owl in silent flight is explained by the variety and arrangement of feathers on its wings.

Large feathers are shaped and serrated like a comb with a pliable fringe, meaning that air is dispersed easily when flying through the air. The feathers are velvety to the touch allowing allows them to absorb noise frequencies, much the same as carpet does. An average wingspan of 140cm also means that barn owls can go further with less flapping of the wings – the main culprit of causing sound.

All of these features have been named by Professor Sharma as the “owl hush kit”. To better understand all of the sound-dulling of the owl hush kit, the team at Iowa State are making use of Argonne National Laboratory’s IBM Mira supercomputer to record the fractional movements of wings and their reactions under pressure.

Is a silent airfoil possible?

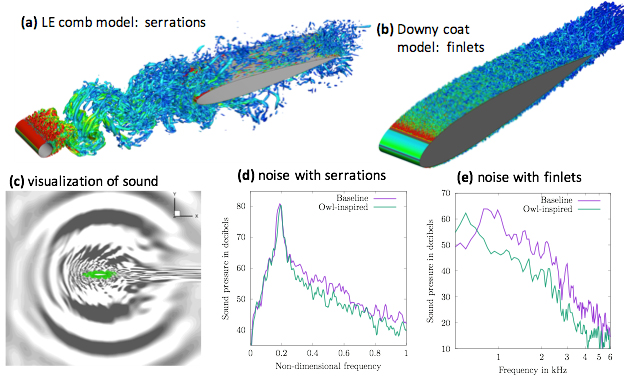

In a study presented by Professor Sharma and associates at the 23rd AIAA/CEAS Aeroacoustics Conference serrations, like those found in the wings of barn owls, were added to the design of a 3D printable airfoil. The design showed substantially reduced noise in comparison with a standard wing baseline. Finlets, a surface model based on the downy structure of feathers, also showed significant reduction, making a promising case for further study.

A future of a bioinspired design

Bio-inspiration is ushering in a new wave of design concepts effectively shaping future fashions, electronic devices and architecture. As Professor Sharma explains, “Our approach is bio-inspired as opposed to bio-mimicry, our designs won’t look like owl wings.”

“We’re studying the physical mechanisms behind the owl’s silent flight. Then we’re taking simplified geometries inspired by the owl wings and applying those to aircraft wings, rotor blades of jet engines and wind turbines.”

The project, Ultra Quiet Aircraft Propulsion Inspired by the Unique Plumage of the Owl, is funded by a $500,000 CAREER grant from the National Science Foundation and $100,000 from the Iowa Space Grant Consortium, supporting Professor Sharma and aerospace engineering students: Andrew Bodling, Bharat Agrawal and Vishal Vijay.

Don’t miss out on 3D printing research progress – subscribe to our newsletter, follow us on Twitter and like us on Facebook. Register for 3D printing jobs here.

Featured image shows a barn owl in flight. Photo by Pete Whieldon