Essentium Inc., a Texas-based 3D printer provider, has announced a series of expansions in response to growing demand for its High Speed Extrusion (HSE) 3D printing platform. These include scaling up the production of the HSE FDM 3D printer, accelerating material development, and expanding global operations with new leadership appointments.

Essentium credits the market response to its open 3D printing ecosystem, developed in collaboration with multinational chemical company BASF and 3D software developer Materialise. The HSE platform’s open market model offers customers greater control and choice in hardware, software and materials. Blake Teipel, CEO and Co-founder, Essentium Inc., comments “When you remove the roadblocks to innovation, you enable customer success.”

“There are no better proof points than an expanding pipeline and growing customer demand to illustrate how much the manufacturing market is responding to open ecosystems and the freedom to innovate on their own terms.”

Creating an open market model for the 3D printing industry

The open ecosystem partnership between Essentium, Materialise and BASF was first announced in November 2018, where the three companies agreed to advance high-speed additive manufacturing. Bart Van der Schueren, Materialise’ CTO explains that the partnership was formed in order to “promote a more open market model, which will fuel the adoption of 3D printing in the industrial field by offering users more control, more choice in materials and ultimately lower cost and higher volumes.”

Essentium had previously worked with BASF to develop materials for the HSE platform, and under the partnership, both firms set towards establishing a global materials supply chain network for HSE as well. Materialise on the other hand joined forces with BASF and Essentium to develop 3D printing software for the HSE 3D printer. Following on from the initial partnership, Essentium closed a $22.2 million series A funding round in January 2019, led by BASF Venture Capital and featuring the participation of Materialise.

Scaling 3D printer production by planning ahead

Essentium’s decision to ramp up the production of its 3D printers is based off the growing pipeline for the HSE platform, as well as the strength of the market response to its open ecosystem. Speaking with 3D Printing Industry, Lars Uffhausen, CFO, COO and Co-founder of Essentium explains that the company’s overall 3D printer shipments is expected to expand by at least 30% as a result of the expansion.

Uffhausen attributes the company’s ability to scale up its HSE 3D printer production to foresight. “[Essentium’s] vision has always been to make industrial-scale additive manufacturing affordable and accessible to the entire manufacturing industry.” In order to carry out its goal, the company recognized at an early stage it would have to scale its manufacturing processes once it shifted from proof of concept to full production.

Therefore, Essentium had taken various steps revolving around customer feedback and supply chain management, to ensure and understand the scalability of the HSE 3D printers: “We took pre-orders so we could better understand our early scale, and we worked closely with our Early Access Program customers to refine the machine, allowing us to make a world-class product,” explains Uffhausen.

“The commitment, participation, and partnership of our customers through the beta cycles has been incredible, their contribution to our platform means that the shift from beta to full production is simple and fast. Because manufacturing and production are in our DNA, we built a network of partners and supply chain early.”

Doubling down on material innovation

Uffhausen also states that Essentium revenue is “growing by 100% each month and is anticipated to do so throughout the year, which is a significant indicator of customer adoption of our platform.” The company explains that the month-on-month revenue growth is being fuelled not only by full production of the HSE 3D printer, but also by increased material shipments. Essentium is therefore focusing on further developing its material offerings, as the company has already released seven new materials so far this year, including TPU 80A-Z and TPU 90A-FR.

To support the expansion of its international operations, Essentium has also made a series of appointments. Benoit Valin, who has previously served as Director of Business Development across Asia for Ultimaker, has joined Essentium as General Manager for the Asia Pacific region.

The company has also appointed Cyprien Decouty as Channel Sales Manager for Europe, Middle East, and Africa (EMEA). Decouty has previous experience as Director of Channel Sales for 3D printing manufacturers AON3D and Formlabs in the EMEA region as well. Uffhausen concludes by stating that “With Benoit Valin and Cyprien Decouty, we now have the strength of expertise and experience in Asia Pacific and EMEA to enable our growth.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

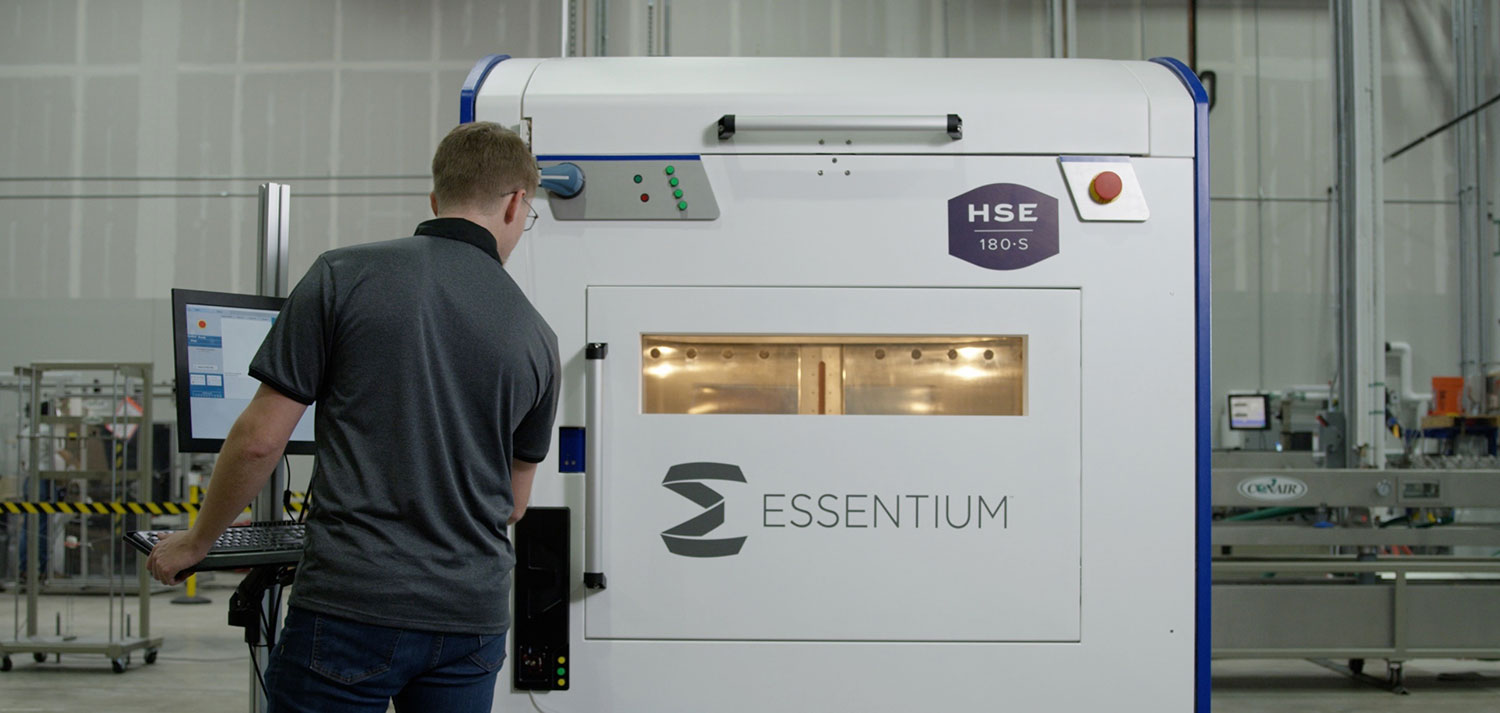

Featured image shows Inside the HSE 180•S. Photo via Essentium.