Remet, a Polish steel structure manufacturer, has opened a €2.8 million ($3.1 million) metal 3D printing laboratory in Stalowa Wola with 3D Lab, a Warsaw-based 3D printing service bureau. 3D Lab helped to equip the facility with 3D printers from leading OEM 3D Systems, as well its own ATO Lab metal powder atomizer.

Remet opened the laboratory as it sought to implement additive manufacturing into its production workflow. The company is also looking to complete research into 3D printing materials and manufacturing processes. The facility will therefore house a whole range of devices and machines supporting both research and production for additive manufacturing. Remet’s 3D printing laboratory also represents the first installation of 3D Lab’s ATO Lab machine.

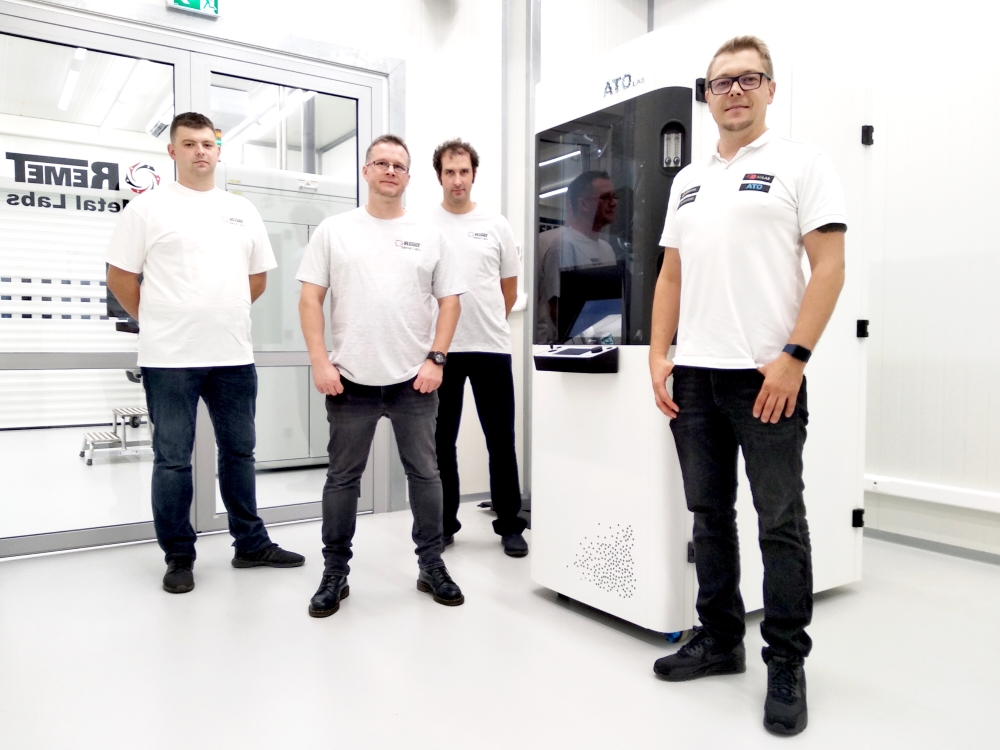

Remet Metal Labs 3D printing laboratory

Established in 2004, Remet manufactures steel structures for the oil and gas, power generation and offshore industries. The company produces complex assemblies to help firms extract oil and gas from the bottom of the seas and oceans. It has served large firms within these industries, such as BP, Statoil, GE Oil & Gas, and ExxonMobil.

Currently, Remet manufactures its assemblies using CNC machining processes. However, it has launched a new division, titled Remet Metal Labs, dedicated to implementing comprehensive projects in the field of additive manufacturing for automotive, aerospace and space industries. The 3D printing laboratory will be headed by the new branch.

In Remet Metal Labs’ new facility, the company’s 3D Systems machines include the DMP Flex 350 for metal 3D printing, and the Figure 4 SLA 3D printer for plastic. Both were installed by 3D Lab, an official 3D Systems reseller.

Remet intends to utilize the DMP Flex 350 in conjunction with the ATO Lab atomizer, a machine for producing metal powders using ultrasonic atomization technology. The ATO Lab system is designed for researchers, and is capable of several hundred grams of throughput. Both the DMP Flex 350 and ATO Lab systems will be used by Remet to test and produce a wide range of powdered metal alloys with different chemical compositions and fractions, with the intention of creating highly flexible prototypes.

The DMP Flex 350 metal 3D printer, a Direct Metal Laser Sintering (DMLS) system, was launched by 3D Systems in late 2018 as a successor to the ProX DMP 320. It comes equipped with a module and software allowing users to adjust the laser and its power. This will enable Remet to manufacture parts with different properties using the metal powders created with the ATO Lab atomizer.

The Figure 4 will be used for adding additional elements to metal 3D printed products, as well as testing ideas during early stages and pre-processing. The 3D printing laboratory will also include scanning microscopes, an ultrasonic screen for the separation of powders, a heat treatment furnace, a laser welding station and a system for machining printed details.

The ATO Lab atomizer

Formerly known as ATO One, 3D Lab first introduced its metal powder atomizer at Formnext 2017 as a concept machine. It was dubbed as an “office-friendly” system and was created in response to increasing demand for metallic powders of varying sizes from SMEs, powder producers, and scientific institutions.

A year later at Formnext 2018, 3D Lab launched its ATO Lab machine, presenting the final and updated version of its atomizer to the public.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the DMP Flex 350 installed at the Remet Metal Labs facility. Photo via 3D Lab.