The 3D Printing Industry team was in Frankfurt all week to see first hand what has become probably the most important event on the 3D printing calendar.

Formnext is now a vast show spread over two large halls at the Frankfurt Messe. This year we’ll be breaking down our review into two separate articles. You can expect more detailed reports in the days to come, but for now here is our review of formnext 2017 – hall 3.

Attendees from last year may remember that hall 3 was the venue for the exhibitors night party – and indeed the Thursday night party again took place in the same hall. However the majority of the space is occupied by 3D printing enterprises and also is home to the conference stages that were previously tucked away on upper levels of the Frankfurt Messe. A new addition for 2017 is the am4u area, which features a jobs board and the opportunity to network with potential employers.

Walking along row G from the conference stage, where Terry Wohlers delivered his opening keynote address on a 3D printed future, attendees could find Markforged at H40. The company has significantly expanded their booth from last year. Banks of the award winning Mark Two were flanked by the Mark X and newer machines.

Next to Markforged was Singapore’s Nanyang Technological University, who I visited the week before formnext at the NAMIC Additive Manufacturing summit in Singapore.

At booth G16, Sondasys from Poland displayed an industrial SLS additive manufacturing system, the company are the latest 3D printing OEM to emerge from the country, joining Zortrax, Sinterit and 3Dgence who are all in hall 3.1. The Sondasys SLS System was available for €175k during formnext, a discount on the final expected price of €200-220k

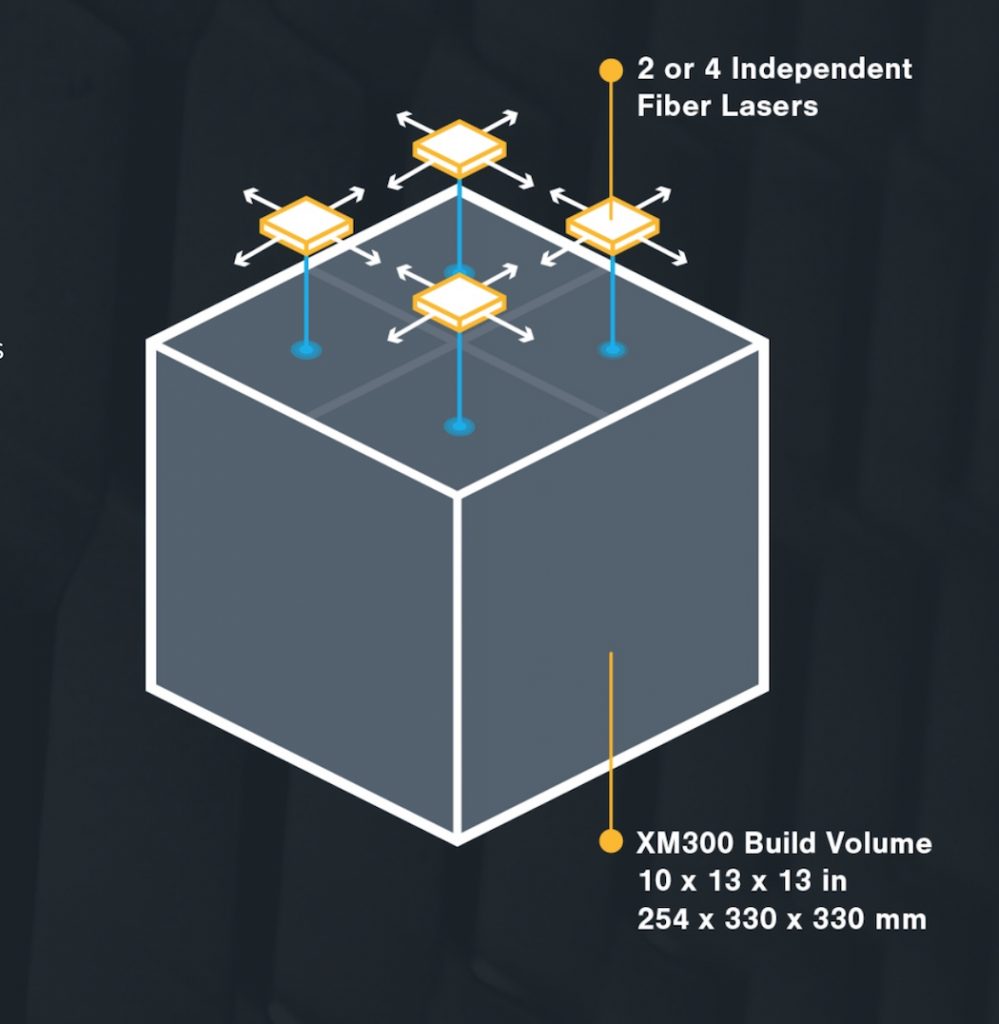

At booth F05 Juan Mario Gomez from Xact Metal – who we first met at RAPID – tells me the Xact XM200 metal 3D printer is currently finishing validation and certification by end of year, shipping will begin Q1 for the $120,000, 250W fiber laser based machine. The company has also just announced a new machine, the XM300. This has a larger build volume of 254 x 330 x 330 mm – compared to the 127x127x127mm of the XM200. Mounted on wheels the Xact Metal 3D printers are designed for ease of transportation, and hoping to find a market at research and academic facilities among other locations.

“The XM300 uses patent-pending Xact Core™ technology, a highly scalable gantry

system platform that allows light, simple mirrors to move quickly and consistently

above the powder bed on the X-Y axis,” said Matt Woods, CTO of Xact Metal. “It’s

equipped with two or four high-precision independent fiber lasers, meaning that parts

can be printed up to four times faster. The system also has twin feed chambers,

which lowers build time and increases productivity.”

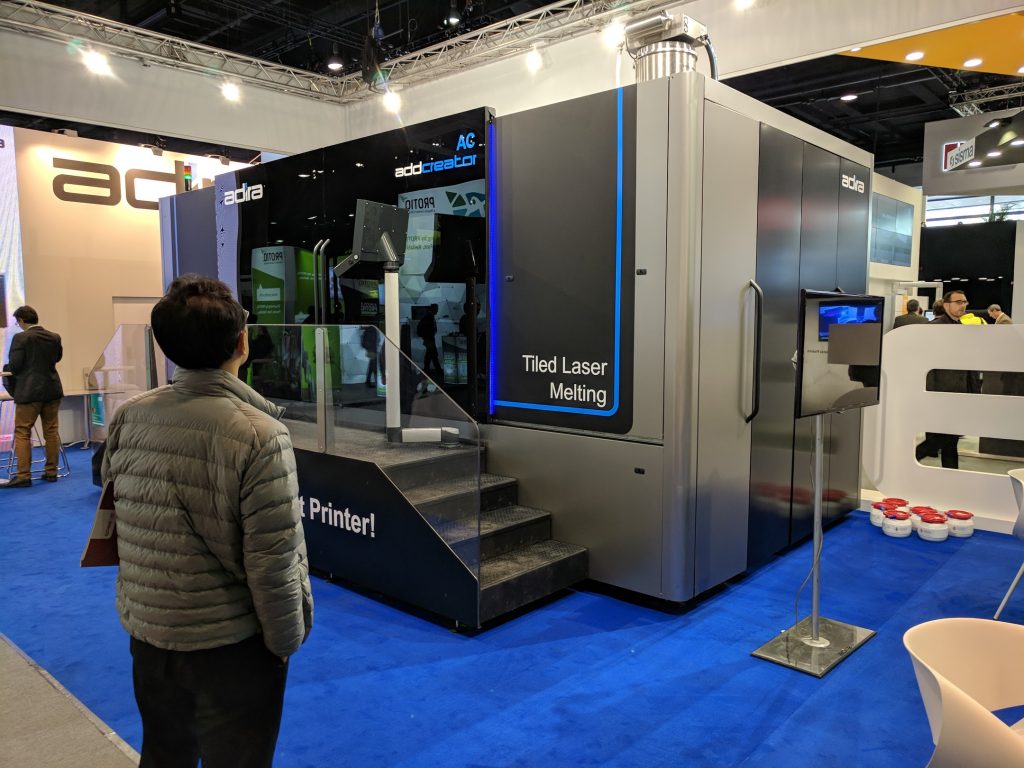

One additive manufacturing system that would be much harder to move can be found at booth E10. Adira were boasting the “world’s largest metal part printer”. From Portugal the company specializes in the development of solutions for sheet metal processing. The Adira AddCreator uses an additive manufacturing technology the company call Tiled Laser Melting (TLM). This method “divides the existing work area in smaller segments or tiles, which are processed sequentially”.

At booth C09, 3DCeram had the Ceramaker. Uses for the 3D printer including bone substitutes, foundry cores and spatial optics – for example innovative satellite mirrors – are featured. During conversation at the 3DCeram booth I learned the company will book double digit sales of the Ceramaker – a 3D printer that retails for between €300-450k, depending on the options selected.

Voted 3D Printing Start-up of the year by 3D Printing Industry readers, Desktop Metal displayed their production system and also brought their furnace to Frankfurt. With single pass jetting the company say they can produce upwards of 560 parts per day.

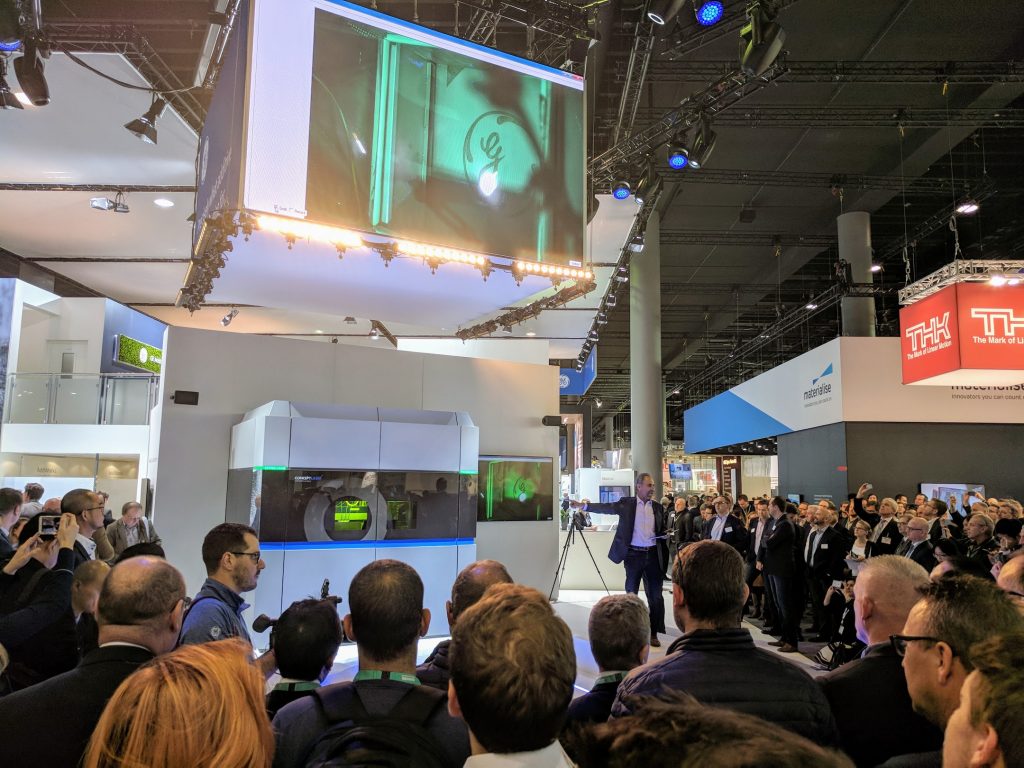

The biggest booth award at formnext 2017 went to the multi-storey blue and white structure built for GE Additive and home to AP&C, Arcam, Concept Laser and DTI. It was a fitting space for the unveiling of the ATLAS.

3D Printing Industry first reported the development of a new metal 3D printer by GE in April, then in June the ATLAS was officially announced.

Developed with Concept Laser in the remarkable time of 177 days the ATLAS series will offer metal 3D printing at a range of sizes, with the largest build volume announced as “meter-class” in two of the three directions.

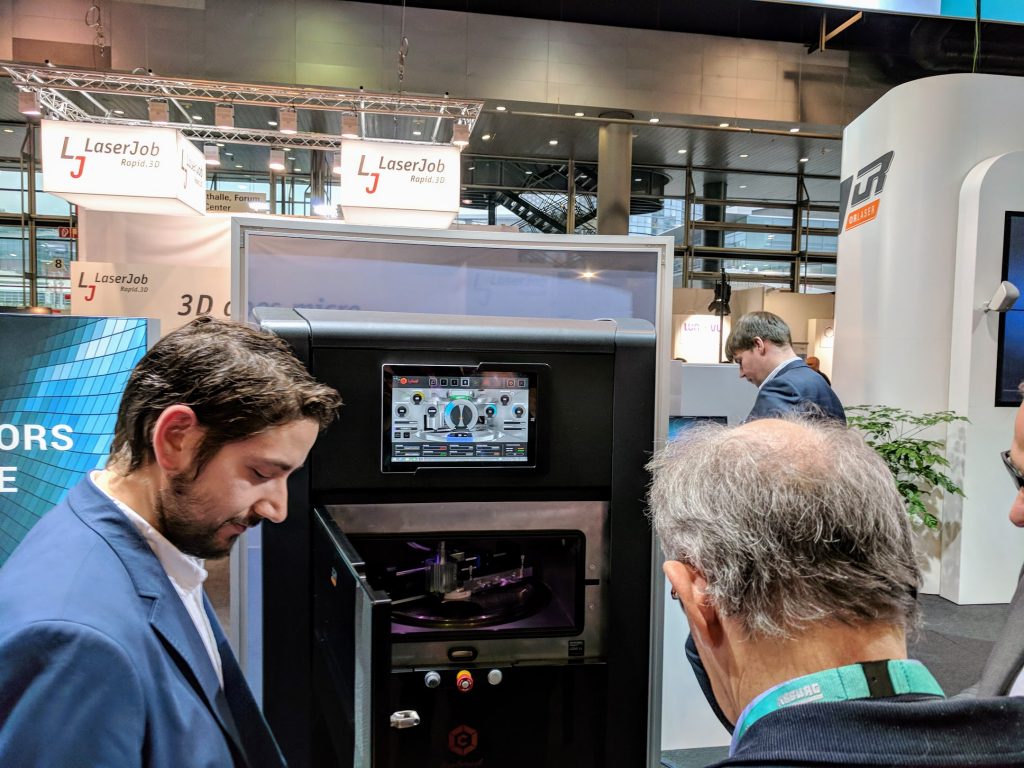

Other notable booths included OR LASER (C20), who have expanded substantially since their debut at formnext 2016. OR LASER brought an enhanced version of the OR Creator metal 3D printer, the ORALAS CUBE – a directed energy deposition system – and also their latest system the ORLAS CREATOR Hybrid. The hybrid system features a 3-axis mill intended to allow finishing of the metal components made on the machine.

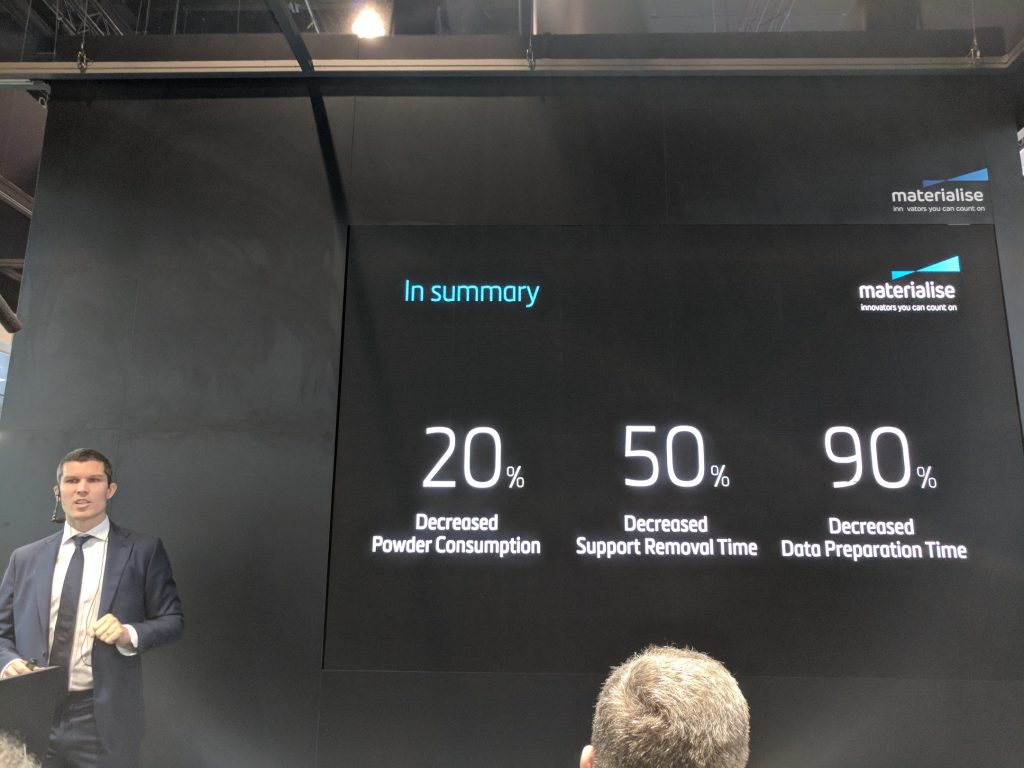

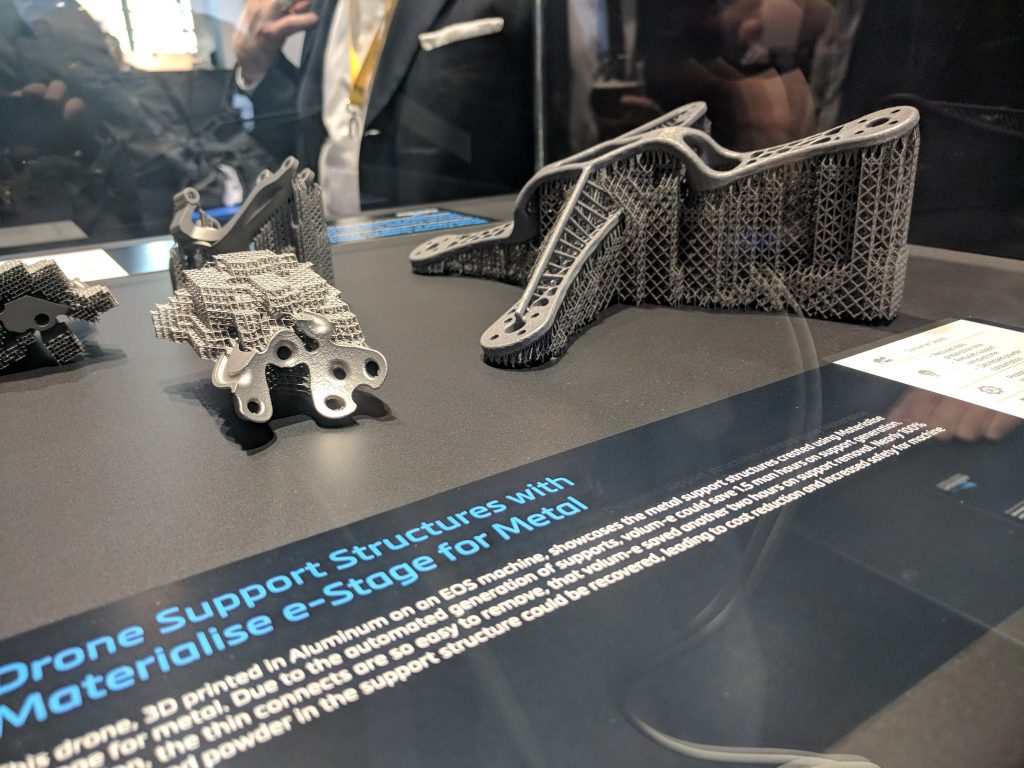

While at C48, Materialise was highlighting the digital supply chain. But visitors can also win surprises on the ‘super mega 3D win thing’. More importantly, Materialise announced the extension of their e-stage software, adding support for metals, we’ll be taking a more detailed look at this development soon.

Additive Industries had the MetalFAB1 at booth F40, and also the world premiere of their Product Removal Module. A Sauber F1 car illustrates several uses of additive manufacturing technology including a front wing benzing made from aluminium alloy to enable wind tunnel testing.

Siemens also had a multilevel booth and were highlighting intelligent automation systems together with a staggering number of partners, including DMG Mori, Vader systems, Stratasys, Adira of Portugal and EOS. Over at E70, the SLM booth was a popular meeting spot. Guests at formnext could relax in the wooden panelled cabins where much business was conducted. AMUG even had their own table reserved here.

At C90 Spee3D promised “your parts, your way” with manufacturing grade metal 3D printing, while health and safety requirements meant that 3D printing a component live would have been problematic – the demo was suitable appealing to draw a large crowd keen to learn more. We’ve reported several times on the cold spray technology used by Spee3D, and you can read our detailed explanation of how the technology works here.

With an extra 106 exhibitors compared to 2016, we’ve hardly scratched the surface here. We’ll be heading upstairs to see more of the 467 exhibitors and bring you part two of the 3D Printing Industry review of formnext 2017 soon.

For all the latest additive manufacturing news, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.