After yesterday’s kickoff with keynote speeches, the RAPID + TCT trade show exhibition is now open. Over 300 exhibitors cover the floor at the David L Lawrence Convention Center in downtown Pittsburgh, displaying the latest 3D printing and additive manufacturing technologies.

3D Printing Industry took a morning jog through the 3D printing trade show to bring you our first look at some of the technology on display.

Hybrid Additive Manufacturing with reactive metals

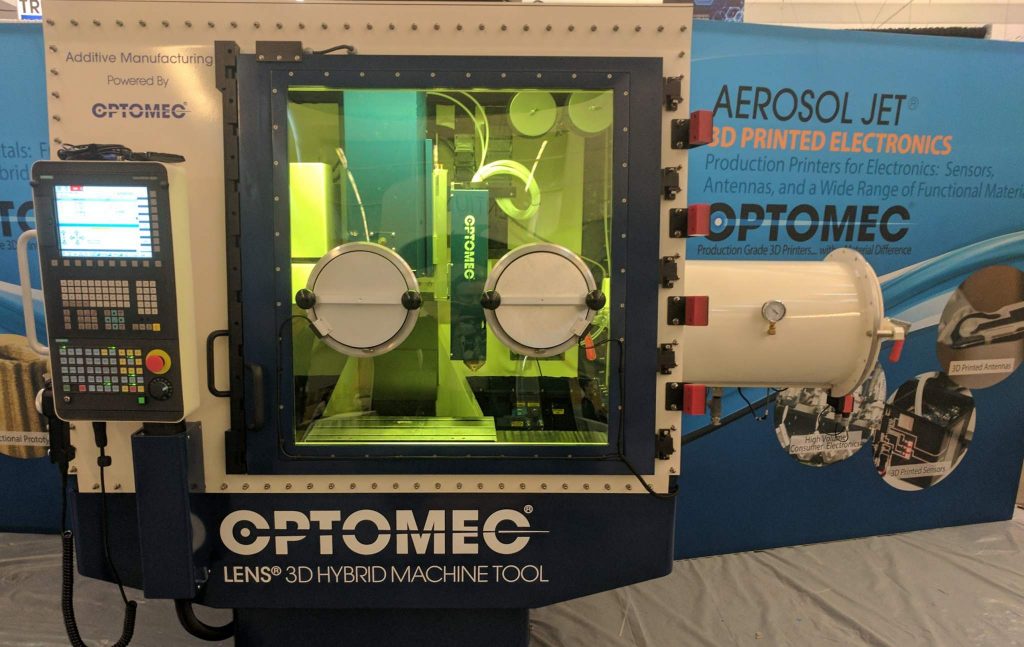

Optomec’s LENS technology finds new application via the LENS 3D Hybrid 20 Controlled Atmosphere. The hermetically sealed Class 1 enclosure contains a LENS laser deposition head running either a 500W or 1KW Fiber Laser. Laser Engineered Net Shaping (LENS) blows metal powder via Argon gas into a melt pool at a rate of 0.25 lbs./hr at 500 W or 0.5 lbs./hr with the 1 kW laser option.

The LENS 3D Hybrid 20 CA introduces full CNC machining capability with a 10 station automatic tool changer. The build chamber can be purged to maintain an atmosphere with oxygen and moisture levels below 40 ppm. Optomec’s Ken Vartanian tells me that this means working with reactive metals such as titanium is now possible in a hybrid additive system.

The LENS 3D HY 20 CA System can also be used in an open atmosphere for less demanding materials. Parts can be removed via a “diving bell” airlock on the right hand side of the machine and manipulated using the glove holes built into the yellow laser safety glass.

BeAM were featured in the Start-up area at Formnext 2015, when we met up with the company at IMTS last year and again at Formnext in 2016 the progress at the company was evident.

Competition for affordable metal 3D printing increases

Desktop Metal are unmissable at the 2017 RAPID + TCT show. The company’s impressive booth filled is with multiple Desktop Metal Studio systems, the microwave furnace and the much larger Desktop Metal Production system.

Markforged are also present at the show and together with expertise in composites are turning their attention to a metal 3D printing method. You can read more about Markforged CEO Greg Mark’s plans for the future of 3D printing here.

3DEO brings low cost, high volume, metal additive manufacturing

3D Printing Industry first featured the work of Matt Petros, CEO 3DEO, in 2014. A research paper, Selective Inhibition Sintering: The Process for Consumer Metal Additive Manufacturing, was co-authored with Dr. Behrokh Khoshnevis and Payman Torabi and addresses the need for a metal additive solution in which high performance meets low cost. 3DEO’s Intelligent Layering technology, “unlocks high volume metal AM by drastically reducing final part cost.” To do this 3DEO work with Metal Injection Molding (MIM) powders, this brings a remarkable cost saving and opens up a material palette familiar to many industrial enterprises.

CEO Petros tells me 3DEO are manufacturing in stainless steel 17-4PH and 316L. With engineering level tolerances and part density of 97% the company is quickly gaining attention, if you can’t make it to RAPID + TCT to speak with 3DEO, we’ll bring you a more in depth report soon. Subscribe to our newsletter to be the first with the latest information.

OR Laser and Xact Metal – price drop on metal 3D printing

OR Laser caused a few waves at Formnext 2016 when they presented their ORLAS CREATOR. At RAPID + TCT the machine is priced at $82,000 and offers a metal additive manufacturing solution with applications in dental, jewelry and other areas where the 100 mm x 110 mm build volume is advantageous. The price, but also the size of the OR Laser machine is remarkable. This metal 3D printer weighs approximately 350 kg (770 lbs).

The Xact Metal XM200 weighs in at 227 kg (500 lbs) and is on wheels. CEO Juan Mario Gomez encouraged me to give the metal additive machine a push and the machine does appear quite portable, although I suspect the State College, PA based company still used a truck to bring their printer for its first major outing.

With a build volume of 127 x 127 x 127 mm and a 250W Fiber Laser, CTO Matt Woods says the machine can print 20-100 μm layers with a spot size greater than 10 microns. The Xact Metal XM200 uses 316L Stainless Steel and Inconel 718 Superalloy, Titanium 6Al 4V, Aluminum Si10Mg and Maraging Steel are all under development. The machine is priced at $120,000, the company aim to provide “High-performance printing and industrial quality at an affordable price.” Xact are at booth 737 and will also be at Formnext later this year.

For all the latest 3D printing industry news, subscribe to our free additive manufacturing newsletter and follow our active social media accounts.

Voting closes soon in our 3D Printing Industry Awards, the winners will be announced on the 20th May at a gala-dinner in London. You can see the shortlists and make your vote here.

If you’re at RAPID + TCT this week, then say hello to our editor-in-chief, Michael Petch.