HP’s Multi Jet Fusion (MJF) is the new modulation of 3D printing that everyone has been talking about recently. But there is another new additive manufacturing process that may be about to gain a place on the lips of industry insiders as they deliberate. The Center for Rapid Automated Fabrication Technologies (CRAFT) at the University of Southern California has been the base of research for Selective Inhibition Sintering (SIS) with an aspiration to create an affordable, high quality consumer (sub-USD$5000) metal printer. How? By reversing the sintering process used in industrial additive manufacturing machines.

‘3D printing,’ the de-facto world view terminolgy, is a set of technologies also known as additive manufacturing (AM) – the industrial standard definition. AM in essence means ‘making by adding’ — using high and / or concentrated energy forming. There are other synonmyns for this generic technology set relative to their utility: such as rapid production and rapid prototyping. There are other, less used, hypernyms such as freeform fabrication. ‘3D printing’ as a term originated as a label for just one modulation of (one production method using) this technology set: making by adding in layers via inkjet heads, before becoming a hypernym for this and all other AM processes. In the popular consciousness the term ‘3D printing’ is also affiliated with ‘prosumer printers,’ also known as ‘desktop manufacturing’ or the ‘desktop factory.’ These are low-to-middle quality desktop sized machines that utilise a narrower proportion of the total range of making by adding methods. Low-to-middle quality here being relative to the breadth of range of output quality of AM technologies which include the multi-million dollar machines used by industry*. It is here that Selective Inhibition Sintering may prove to be a meeting point in terminology and technology.

The prime industry report, The Wohlers Report, defines two categories of additive manufacturing machines: consumer and industrial, with consumer 3D printers classified as those that cost less than $5,000. The first consumer (or prosumer, as per Alvin Toffler or 3DPI’s own Juho Vesanto) machines to bring industrial machine additive metal processes to the desktop are almost with us, such as the $3,999 Sintratec Desktop Laser Sintering 3D Printer and $2,500 DIY Ester SLS 3D Printer by Brandon Fosdick. Innovative fruition of industrial grade feedstock for consumer 3D printers is also progressing, such as Turner MedTech’s propriatory GMASS 3D filaments. Also, new modulations that bring metal printing to the prosumer are in progress elesewhere, such as gas metal arc welding (GMAW) that was developed at Michigan Technological University, and liquid metal jetting (LMJ) developed at the University of Texas Arlington. But new processes that innovate affordability for industrial grade metal additive manufacturing at home are yet to materialise. The researchers behind the Selective Inhibition Sintering project believe that this technology may be the one to accomplish that goal.

Dr. Behrokh Khoshnevis and his team at the University of Southern California have based their research upon the promise of the premise to invert the lazer sintering process using inhibitive retardance. Upon each strata of powder layered, piezoelectric deposition of liquid chemical inhibitor in the periphery of the strata of desired output form prevent powder particle fusing. Thus the prevented periphery becomes an impedance boundary to the extremity, which in turn becomes a sacrificial mould upon conventional furnace sintering.

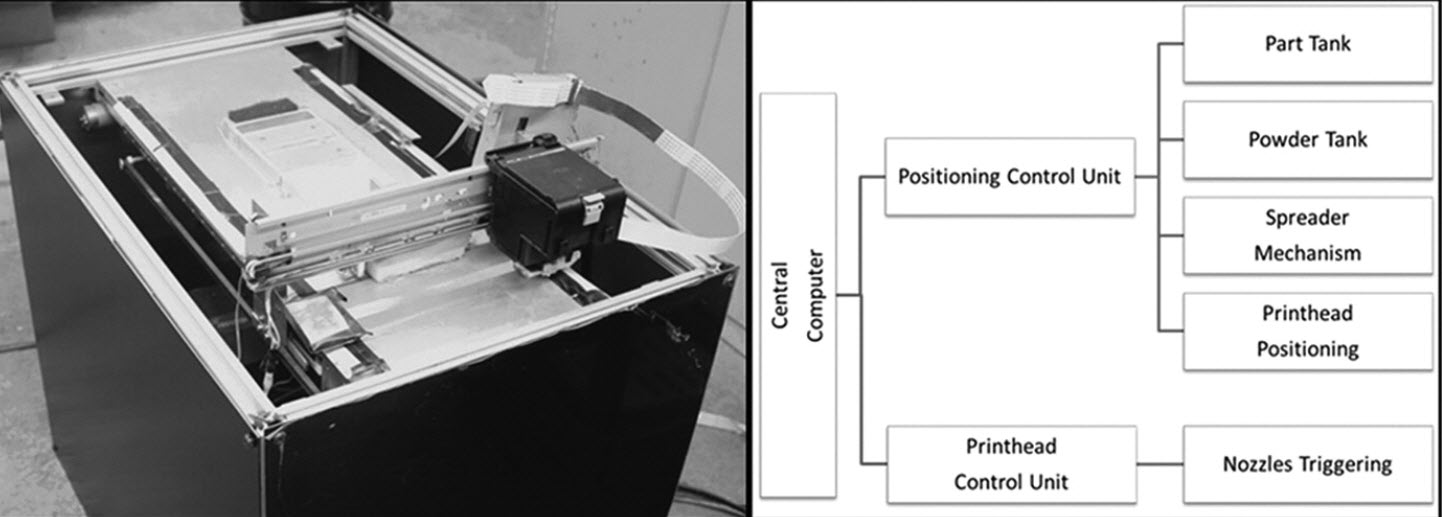

The prototype SIS-metal machine constructed for the research consists of a three-axis motion system, piezo-electric printhead and controller board — with motion control and user interface software.

The summary of the research paper introducing SIS concludes success for the process as“the SIS-metal process has proven adaptable for use in a consumer-level machine by way of an inkjet printhead.” There are adaptive obsticles after this initial stage of prototype: “part strength and porosity have not been characterized for the finished bronze parts. Shrinkage and surface quality of parts may be improved upon as well. It is currently unknown if the intradirectional shrinkage percentage is linear with respect to part length in a given direction. More research will be conducted on variation in interdirectional shrinkage (X vs. Y vs. Z) as well. Lastly, overpenetration of liquid inhibitor results in surface defects in up-facing surfaces of the sample parts. A fine-tuning of inhibitor deposition is planned to avoid these defects.”

*The ‘3D printing industry,’ itself could be said to refer to all markets of all applications of this set of technologies. There is, by standardised definitions, no single extant ‘3D printing industry’ per say, insomuch as there is no single extant ‘subtractive manufacturing industry.’ Rather, there are a number of methods of making by adding that have many applications across many markets.

Source: Kurzweil AI