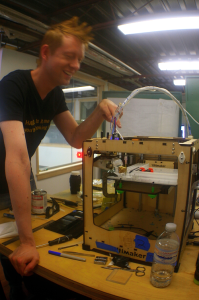

Maker Eric Boyd and his team on Hackaday have cooked up a way to convert your 3D printer into an electronics pick-n-place machine and then back into a 3D printer again when you’re done. The project is called the Retro Populator because, as Boyd explains, it populates circuit boards, by retrofitting a 3D printer.

A pick-n-place machine is a robot that takes electronic circuit board components, like resistors and capacitors, and situates them into specific locations. Maker communities often need small runs of custom circuit boards for their builds and projects; however, the expense of having them created on demand prices them far out of the range of your average Maker, so they often need to be assembled by hand. If you’re only creating 5 or 6 boards, that doesn’t seem to be especially bothersome, but things change when you need 50 to 100 of these custom boards.

A pick-n-place machine is a robot that takes electronic circuit board components, like resistors and capacitors, and situates them into specific locations. Maker communities often need small runs of custom circuit boards for their builds and projects; however, the expense of having them created on demand prices them far out of the range of your average Maker, so they often need to be assembled by hand. If you’re only creating 5 or 6 boards, that doesn’t seem to be especially bothersome, but things change when you need 50 to 100 of these custom boards.

Boyd with his team – consisting of Charles Hartlaub, Adam Evenden and Hackaday user, D1plo1d – submitted their 3D printer conversion to Hackaday and are documenting their project with some great videos and commentary. Take a look at their video overview of the project:

The Retro Populator is designed to easily switch between your homebrewed P&P machine and back into a 3D printer, so you don’t need to sacrifice your printer to the Maker gods for the project to work for you.

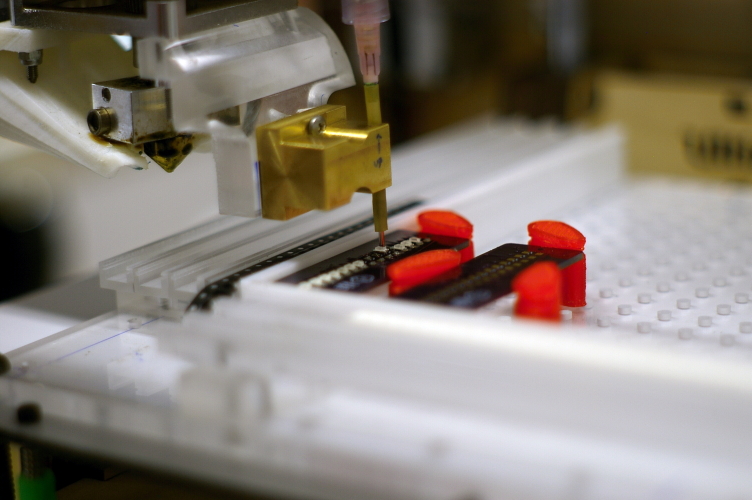

While it isn’t an easy build by any means, it is a simple concept. A small vacuum syringe is attached to the 3D printer’s extruder head, while a small jig adjusts the z-stage re-zero height. Circuit boards are held in place on a CNC-milled, acrylic base plate with 3D printed pegs. Components for circuit boards are generally sold fixed onto a roll of tape, so the base plate has several milled tape holding strips along the sides that allow the printing nozzle to accurately find the part and move it into place.

Here are a few videos showing the Retro Populator in action:

Part two:

Boyd and his team are planning a 2.0 version that will add an additional nozzle, allowing the parts to deposit solder paste at the same time as they’re put into place. And version 3.0 will include precise circuit board rotation. The largest obstacle to implementing these improvements is doing so without any permanent modifications to the 3D printer.

“We want the RetroPopulator to be quick to setup and quick to tear down, so people can easily switch between 3D printing and pick-and-placing,” explained build team member D1plo1d. “Also, as the MakerBots of this world get progressively more blackbox, we wanted something awesome and open source that would just work anywhere, regardless of how closed sourced companies try to make the 3D printing space.”

Currently the team plans on launching a Kickstarter and selling complete modification kits at each stage of development. And, while he estimates the cost to be under $100, they haven’t quite gotten to the pricing stage yet. You can follow the project’s progress over on Hackaday. And the team seems pretty active on the project’s comments section, so feel free to join the discussion.