Researchers from Johannes Kepler University Linz have leveraged 3D printing to produce soft robotics with integrated sensor networks capable of stretching to six times their original length.

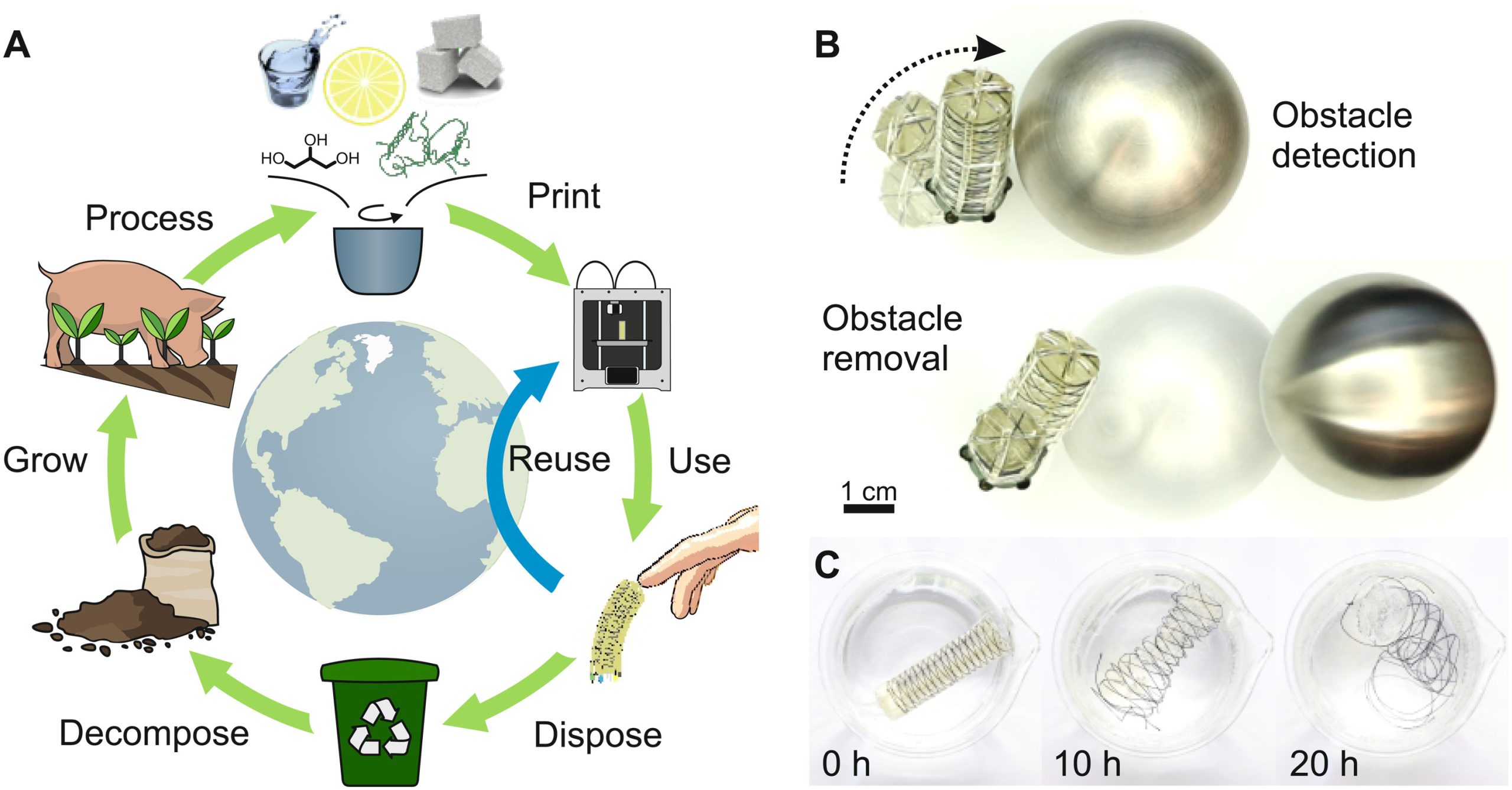

A key focus of the study was to address many of the sustainability concerns posed by the development of soft robotics applications, such as the field’s use of non-biodegradable materials and its subsequent growing environmental impact.

To minimize this, the soft robots 3D printed by the researchers are made up of completely biodegradable materials and can therefore be reprinted multiple times or disposed of hazard-free at the end of their lifetime.

More sustainable soft robots

According to the Linz scientists, while soft robotics often take inspiration from nature in terms of their function, the materials involved in creating these applications tend to be non-biodegradable or stem from non-renewable sources. The team identified that the field needs to improve its sustainability credentials due to the currently limited lifetime of soft materials, or for applications where deployed robots cannot be retrieved.

Additionally, conventional manufacturing methods such as mold casting are often unable to replicate the complexity of nature’s creations. Previous work has been undertaken into biodegradable soft robots using such conventional techniques, however the robots produced are limited in terms of their geometry and feature size.

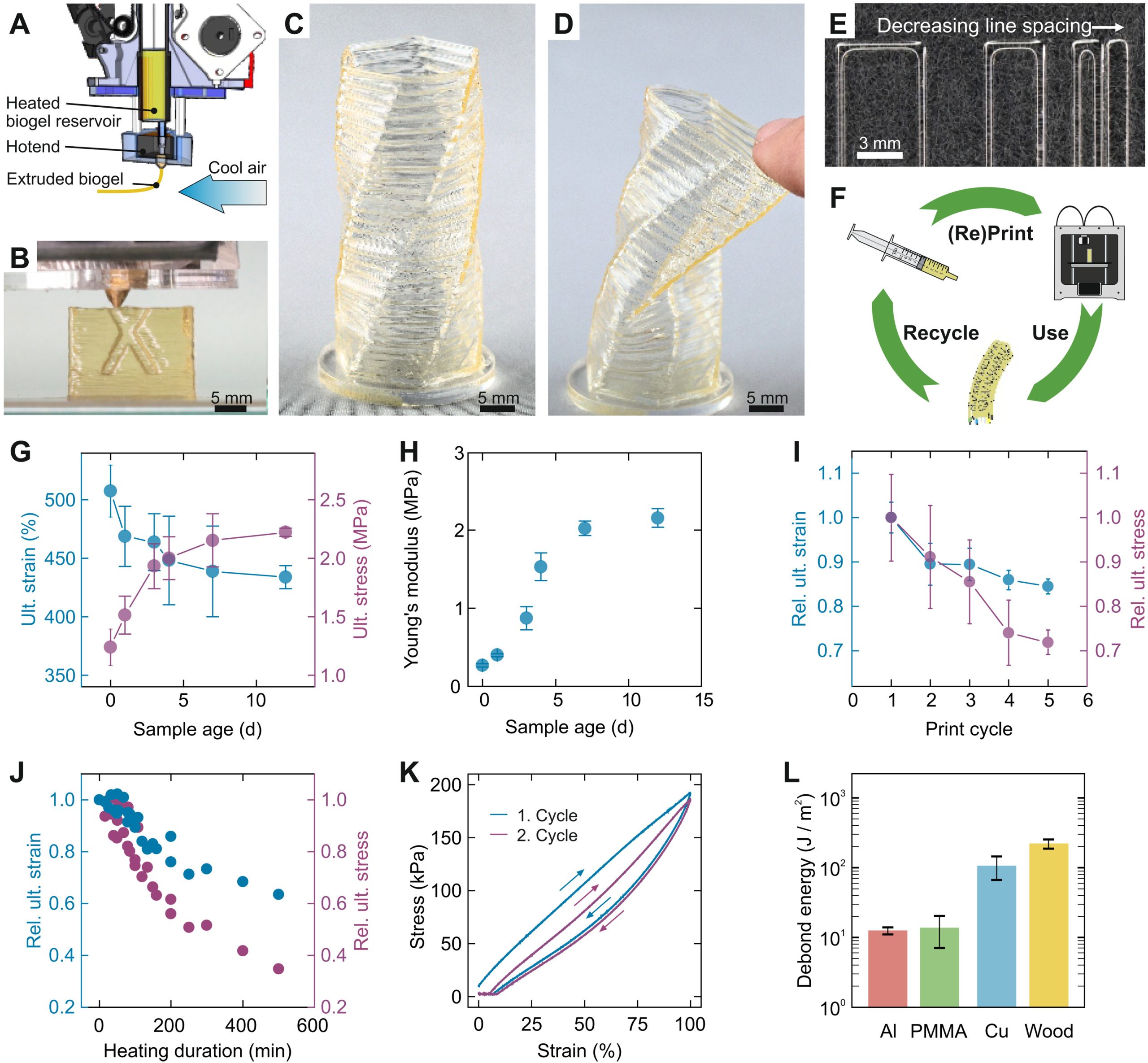

To solve both of these concerns, the researchers developed a customized FDM-based additive manufacturing process to print a fully biodegradable gelatin-based ink into stable, complex soft robots with integrated sensor networks.

Achieving biodegradable soft robots

The researchers set out to improve upon existing approaches to soft robots that lack the mechanical stability, reusability or biodegradability necessary for wholly sustainable and practical devices.

They based their technique on entirely degradable gelatin-based hydrogels which, when supplemented with glycerol and sugar syrup, delivered desirable tunability and stretchability properties. The biogels’ thermoreversability enabled them to be reused in subsequent printing processes up to five times while maintaining their stretchability.

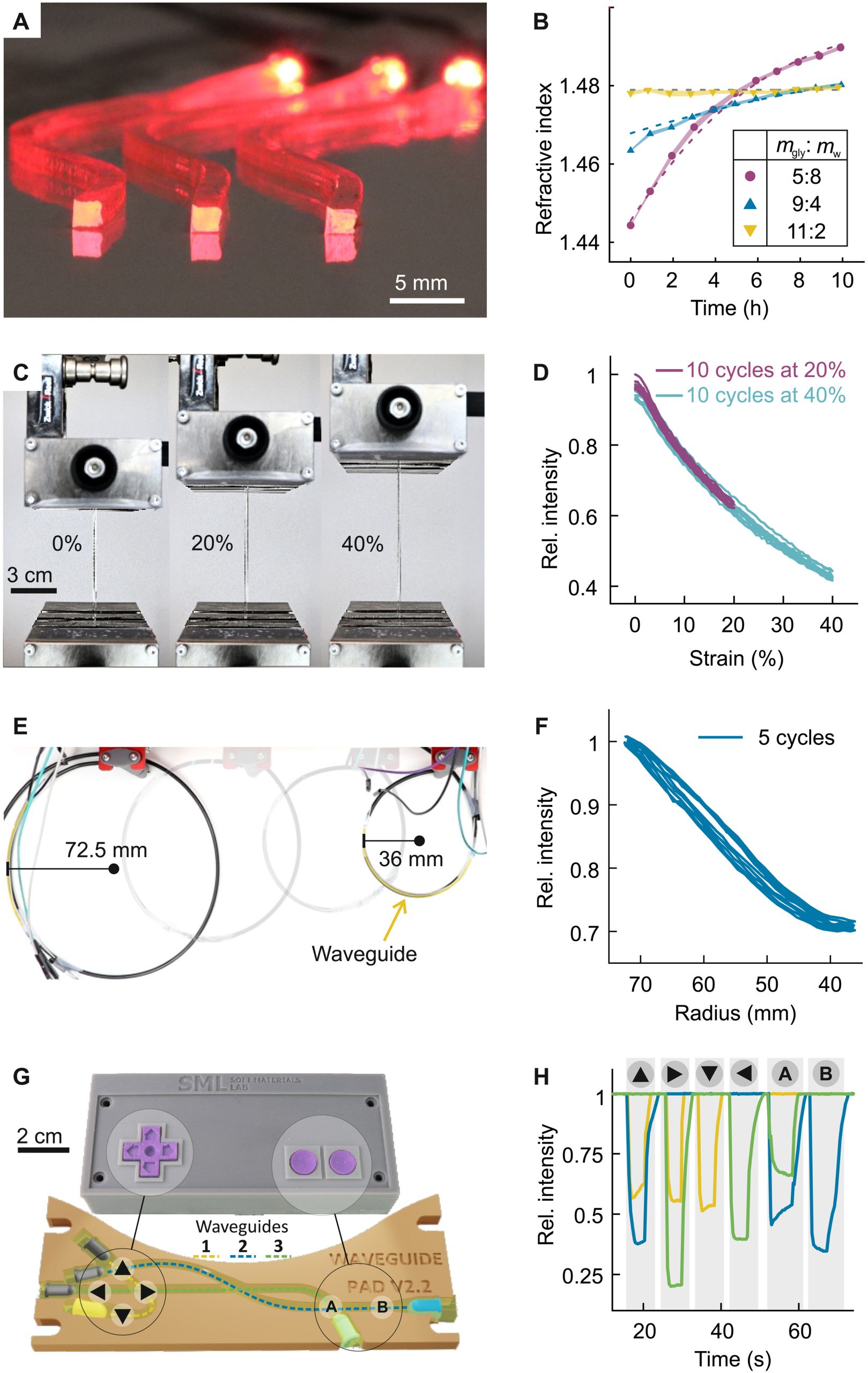

The team adapted an existing paste extruder design and integrated it into a Makerbot 2X 3D printer alongside a two-stage heating system, to enable them to better control the gelation process. Using this system, the researchers 3D printed both the main body of their soft robotic devices and their embedded stretchable waveguide sensors, which gave the devices their proprio- and exteroception capabilities. The integrated networks of stretchable waveguides enabled the soft robots to control their navigation and interact with their surrounding environment through transmitting light.

The 2×2 mm slab waveguides were printed in a one-step process and connected to light-emitting diodes (LEDs) and photodiodes (PDs) to complete the sensors. The waveguides functioned as touch sensors when they came into contact with external objects, as when a region along the waveguide was compressed by an external force, it caused a decrease in transmitted intensity, due to light being absorbed or scattered at the point of force.

The researchers used this effect to build a video game-style controller pad with six buttons, containing a network of three waveguides. When touched, the buttons compress the waveguide network at different positions, enabling the identification of which button had been pressed.

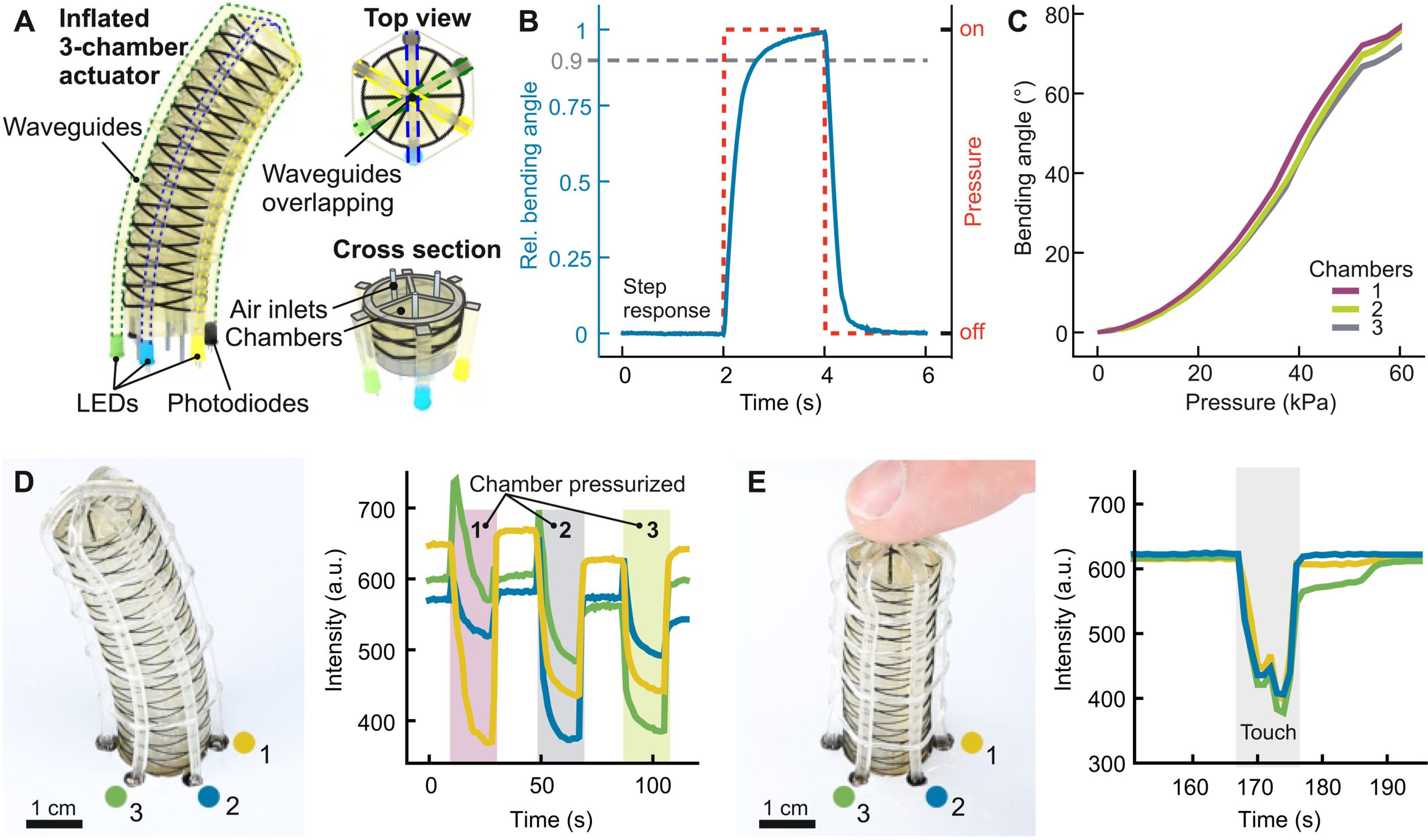

For the soft robot itself, the researchers 3D printed a biodegradable three-chamber actuator spanning 16.6 mm in diameter and 60 mm in height, capable of responding to pressure or deformation within less than a second. They then combined their 3D printed waveguide sensors with the actuator to acquire information on the actuator’s bending state and touch events with objects in its surrounding.

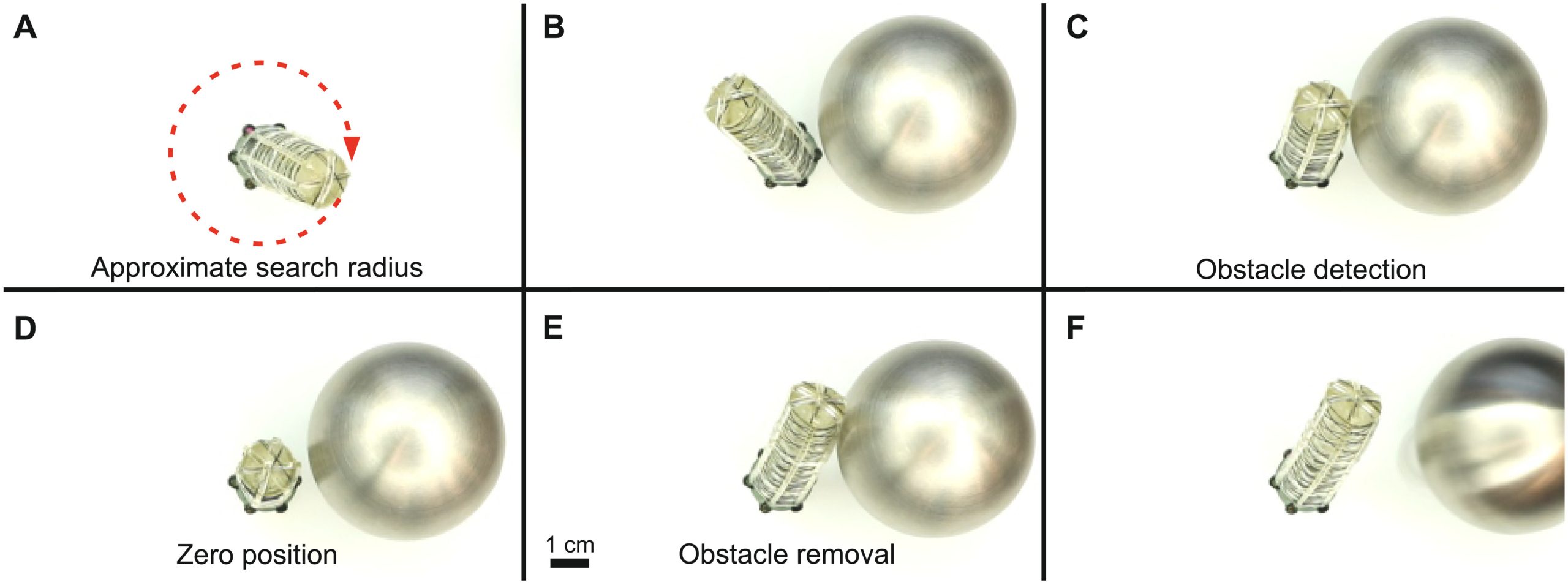

Off the back of this, the team was able to introduce a so-called “search-and-wipe” routine to the soft robotic device to allow it to remove obstacles in its path. The actuator can sense contact events within its path and upon detection pressure is released from all chambers in the direction of the obstacle in order to push it away.

Improving detection capabilities

Despite the success of the study in demonstrating a more ecological approach to 3D printed soft robotics, the researchers identified several areas that could be improved going forwards. They acknowledged that distinguishing between different stimuli, such as bending and touching, was challenging for the device, which could be overcome by implementing distributed fiber-optic networks capable of operating at various wavelengths or light modulation.

The team also said that increasing the complexity of their design will require more advanced actuator shapes and multimaterial combinations, which could be achieved through the development of suitable biodegradable support materials to enable the printing of overhanging features or cavities. Combining mechanically, electrically, and optically tuned biogels to achieve more sophisticated actuator mechanisms would also enhance the sensing and control capabilities of future soft robotic devices.

Regarding sustainable development of the field, the researchers stated that end-of-life considerations are critical, and more reprint cycles could be realized by restoring the printability of the biogels through rehydration, reducing printing temperature, and increasing the printing speed.

Ultimately, the team believes its sustainable 3D printing approach will likely have a “positive influence” on soft robotics through a reduced ecological footprint and waste generation.

More information on the study can be found in the paper titled: “3D printing of resilient biogels for omnidirectional and exteroceptive soft actuators,” published in the Science Robotics journal. The study is co-authored by A. Heiden, D. Preninger, L. Lehner, M. Baumgartner, M. Drack, E. Woritzka, D. Schiller, R. Gerstmayr, F. Hartmann, and M. Kaltenbrunner.

Advances in 3D printed soft robotics

3D printing is receiving increasing attention for novel applications like soft robotics due to the design freedom granted by the technology, and there have been several significant research developments in this space recently.

For instance, researchers at Linköping University have previously developed a set of microactuators for soft micro robotics with 4D capabilities, while a team at Harvard University used 3D printing to develop a school of soft robotic fish capable of swimming in complex patterns thanks to a system of LEDs and cameras.

Elsewhere, researchers from Tianjin University have 4D printed a self-propelling soft robot capable of rolling and climbing on its own, and UC San Diego scientists have come up with a novel method of 3D printing liquid crystal elastomers (LCE) with potential applications as an actuating material for soft robotics.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows search-and-wipe routine. Image via Johannes Kepler University.