The nRugged, a Factory in a Tool (FIT) 3D manufacturing system developed by Florida-based micro-dispensing technology firm nScrypt, has been demonstrated to the Secretary of the Army, Ryan D. McCarthy, as a potential production tool for the U.S. Army.

The machine, designed for harsh environments, was presented by LTC Jason Barnhill of the United States Military Academy’s Department of Chemistry and Life Science (West Point), in association with the Uniformed Services University (USU)’s 4D Bio3 Program and The Geneva Foundation.

Barnhill demonstrated the capabilities of the nRugged by 3D printing an orthopedic screw. According to Dr. Ken Church, nScrypt’s CEO: “nRugged is so much more than a 3D printer. Because it is a version of our Factory in a Tool, it solves the problem of building a precision product, not just a part, and does it in harsh environments. For example, a complete electronic device or a bioactive bandage can be digitally manufactured in the same machine, with automatic tool changes.”

nScrypt microdispensing technology

Founded in 2002, nScrypt is dedicated to developing additive manufacturing, micro-dispensing and bioprinting technologies. Micro-dispensing involves depositing droplets of ink in volumes of less than one microliter, which facilitates multi-material 3D printing. The process also allows the fabrication of smart devices, conformal antennas, and microfluidic devices.

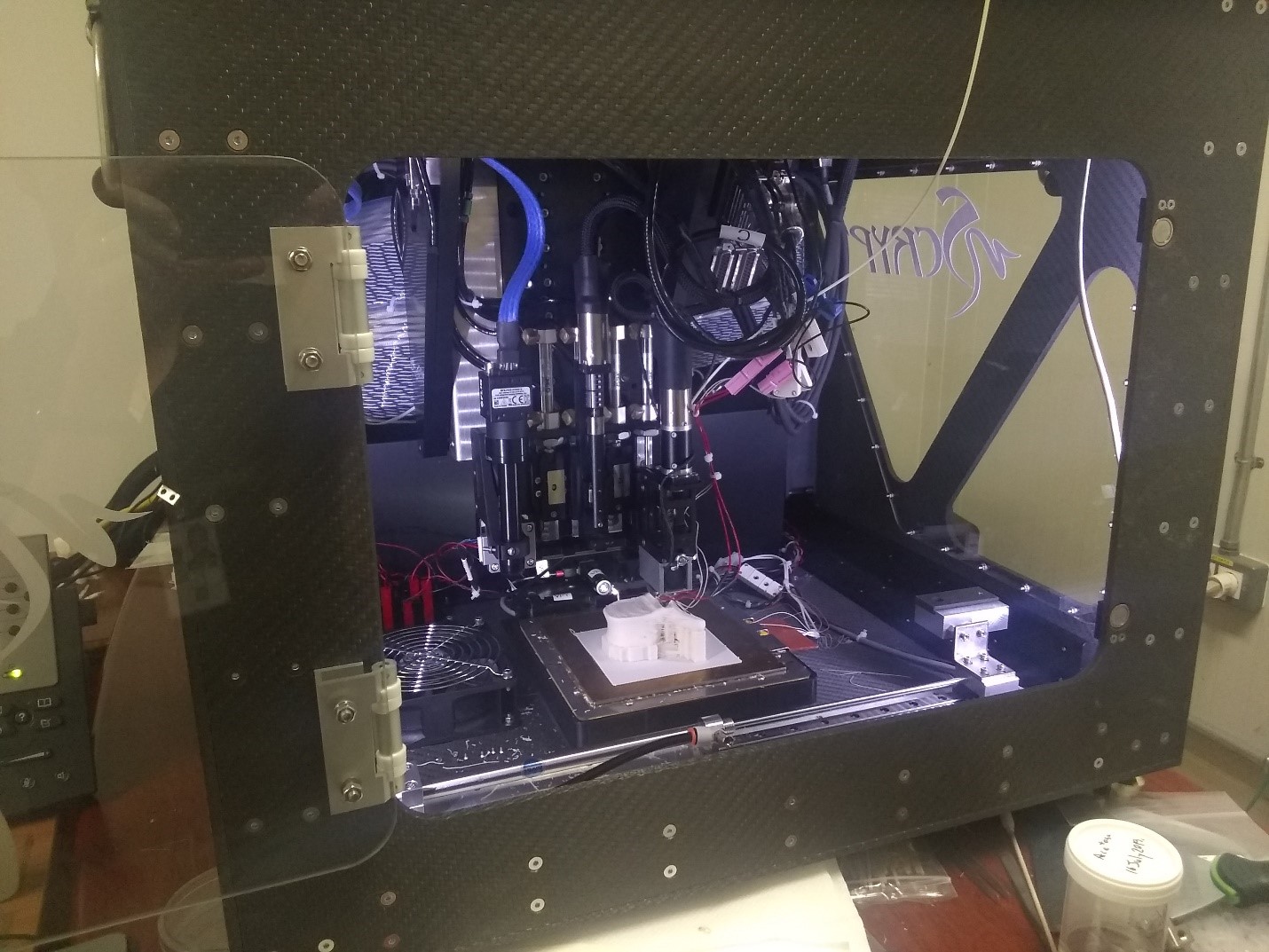

The company’s FiT systems are a composition of microdispensing, material extrusion, micro-milling, and pick and place tool heads with multiple cameras, for an autonomous, hybrid manufacturing process. The machines leverage nScrypt’s patented SmartPump microdispensing tool head, capable of dispensing 10,000 commercially available materials with volume control up to 20 picoliters. Recently, using a new conical pen tip on the SmartPump tool head, nScrypt announced it had successfully 3D printed solder and adhesive dots in the 50-micron range.

nScrypt has previously provided a total of 6 FiT systems to various Army bases and labs, including a 3Dn-1000 machine to the U.S. Army’s Redstone Arsenal base in Alabama for manufacturing phased array antennas.

The nRugged system

nScrypt’s nRugged system was demonstrated to the Secretary of the Army as part of the 4D Bio3 program, a project run by The Geneva Foundation, a non-profit organization that supports medical research and education within the U.S. military. 4D Bio3 aims to promote the development and application of bioprinting, biofabrication, and biomanufacturing technologies for research relevant to Department of Defense (DoD) priorities. The program is based at the USU on America’s Medical Campus in Bethesda.

The nRugged is a ‘ruggedized version’ of nScypt’s FiT digital manufacturing platform. It has been built to withstand and operate effectively in harsh environments, thus making it suitable for deployment in the field during Army operations, thanks to its mobility: “The real advantage of this tough machine is mobility, rapid mobility, while maintaining precision,” explains Church.

“No crate, no riggers, no heavy equipment movers, no technicians to set it up and calibrate. Roll it into position, remove the top, plug it together, and start printing. Move it again and start printing right away. And again, with precision.”

The system can be equipped with up to four tool heads in any combination, including tools for microdispensing material extrusion, milling and polishing, and pick-and-place. It features a 150 x 150 mm print bed, and can also be configured for bioprinting as well.

Previously, nScrypt developed a customized version of its BioFabrication Facility bioprinter, called the Austere BioAssembly Tool (ABAT), in order to biofabricate medical products in an austere military environment as part of a 4D Bio3 pilot program.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the nRugged FiT system on the back of a truck. Photo via nScrypt.