Bechtel Plant Machinery Inc. (BPMI) has selected Velo3D’s fully integrated metal AM system for the U.S. Naval Nuclear Propulsion Program.

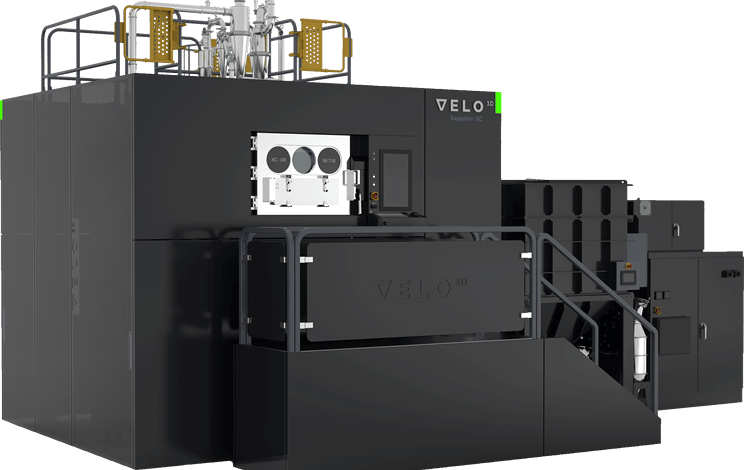

Featuring Velo3D’s Sapphire XC large format printer calibrated for stainless steel 415, the selected solution will be operated by materials company ATI, at its newly established additive manufacturing facility located outside Fort Lauderdale, Florida. Earlier this year, ATI secured a contract from BPMI to assist in the development of complex engineered part solutions, incorporating metal 3D printing.

By integrating Velo3D’s technology, BPMI and ATI aim to improve part production processes for the Naval Nuclear Propulsion Program. The utilization of additive manufacturing will facilitate the production of parts previously manufactured through casting, thereby reducing lead times for critical components and optimizing the supply chain.

“BPMI and ATI’s progressive approach to 3D printing is extremely forward-thinking and this new, revolutionary facility will significantly augment the U.S. Navy’s supply chain for maintenance, repair, and operations,” said Brad Kreger, CEO at Velo3D. “Both companies are early adopters of metal 3D printing and innovators in the manufacturing industry. We look forward to working with them as they support the U.S. Navy’s fleet, including its aging vessels.”

Additive manufacturing enhances naval fleet maintenance

Velo3D’s technology features a fully integrated software and hardware solution that has been developed entirely in the United States. A standout aspect of Velo3D’s proprietary technology lies in its ability to manufacture parts with complex geometries, all without the necessity for extensive support structures. This addresses challenges frequently faced with conventional 3D printers, says the company.

“Printers with larger build volumes and the ability to print with less support structures are ideal for U.S. Naval Nuclear Propulsion Program applications,” said Nathan Weiderspahn, BPMI Executive Manager, Industrial Base Management. “This additive manufacturing technology will greatly support our efforts in delivering new technology to the U.S. Navy and helping maintain its fleet of ships.”

With approximately 300 vessels currently in operation, many of which have been in service for decades, the U.S. Navy faces the challenge of maintaining aging equipment. Alongside the broader U.S. Department of Defense, they have proactively integrated additive manufacturing into their operations.

This technology has been recognized for its effectiveness in bolstering warfighter readiness and reducing lead times for replacement parts. Additive manufacturing achieves these goals by facilitating distributed supply chains and digital inventories. Manufacturers can now produce parts to specification using any similar printer calibrated for the same metal alloy. The establishment of ATI’s new secure facility, coupled with Velo3D’s fully integrated solution, signifies notable advancement in bolstering the Navy’s maintenance and operational capabilities.

Joe Thompson, the General Manager of ATI Additive Manufacturing Products, emphasized the significant advancements facilitated by their collaboration with Velo3D. Thompson noted that the partnership will enable ATI to produce complex parts more easily, with fewer support structures, at lower angles, and in larger sizes than previously possible.

This expanded capability broadens the range of potential part designs for defense and aerospace customers, leading to enhanced performance and quality. Additionally, Thompson highlighted the substantial business opportunities presented by these previously unproduceable part designs.

Metal AM for a strong defense sector

Defense manufacturing is transforming through the adoption of metal AM, which facilitates the creation of complex, lightweight components and enables swift production of various items ranging from aircraft components to weapon systems. It provides flexibility, cost savings, and the capacity to maintain legacy equipment.

Last year, the US Navy deployed its first Phillips Additive Hybrid metal 3D printing solution aboard the USS Bataan ship. By integrating Meltio‘s laser metal deposition technology with a CNC control mill from Haas, the system facilitates the on-demand production of components. Its objective is to bolster ship self-sufficiency, diminish dependence on supply chains, and accelerate component manufacturing. Essential for naval systems, the system utilizes 316L stainless steel offering economical solutions for component production.

Elsewhere, BAE Systems and AML3D partnered to 3D print metal parts for nine Hunter class frigates for the Royal Australian Navy. With AML3D’s advanced technology and expertise, certified by Lloyd‘s Register and DNV, the partnership aimed to manufacture high-strength components with design optimization and rapid lead times. This strategic alliance marks a significant step forward for both companies in advancing their capabilities in the marine and defense sectors, particularly in support of BAE Systems Australia’s shipbuilding initiatives.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows to support the US Navy’s Nuclear Propulsion Program, Bechtel Plant Machinery, Inc. (BPMI) has purchased a Sapphire XC printer calibrated for stainless steel 415. Photo via U.S. Department of Energy (DoE).