Additive manufacturing software company 1000 Kelvin has partnered with Norwegian Defence Research Establishment (FFI) spin-off Fieldmade to enable the rapid deployment of 3D printers in active combat zones.

Announced during the Military Additive Manufacturing (MilAM) summit and technology showcase, this collaboration will reportedly enhance strategic readiness and operational capabilities in the military sector.

This partnership will see 1000 Kelvin’s AMAIZE platform integrate with Fieldmade’s deployable additive manufacturing solutions, including its NOMAD series of transportable 3D printing modules.

The companies claim that this combination will enable those on the battlefield to start 3D printing as soon as the module arrives on site. This allows users to quickly adapt to operational manufacturing needs.

Taking place in Florida between 16-17 January, MilAM is advertised as the largest military, aerospace, and defense additive manufacturing event in North America.

“Our vision is to make deployable 3D printing as easy as using a vending machine. The integration of 1000 Kelvin’s AMAIZE into our products is a significant step towards this goal,” commented Fieldmade CEO, Jostein Olsen.

“By combining our strengths, we’re not just advancing technology; we’re providing solutions that can save time, costs, and in critical military scenarios, even lives,” added Omar Fergani, CEO and Co-Founder of 1000 Kelvin.

AMAIZE and NOMAD to combine on the battlefield

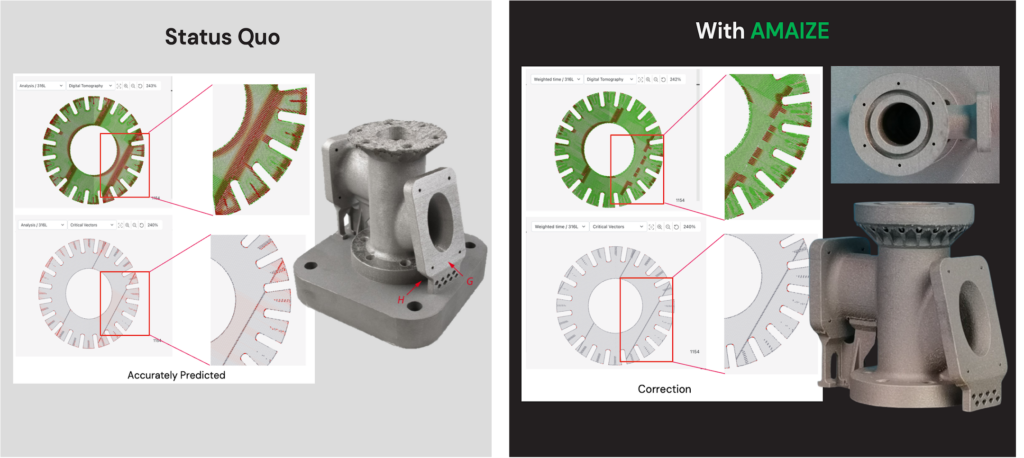

1000 Kelvin’s AMAIZE software combines artificial intelligence (AI) with physics and manufacturing data to provide an ‘AI-copilot’ to additive manufacturing engineers. Launched to market at Formnext 2023, AMAIZE creates optimal 3D print ‘recipes’ which ensure parts are 3D printed correctly the first time.

Once a 3D print file is uploaded to the AMAIZE cloud, the software analyzes the part and automatically addresses any thermo-mechanical issues by optimizing scan strategy and process parameters.

This streamlined approach is said to eliminate the need for expensive finite simulation software, minimizing the need for multiple physical iterations in the process. This limits material waste, cost, and energy usage. 1000 Kelvin has already announced initial AMAIZE collaborations with 3D printer manufacturer EOS and an unnamed California-based rocket launch provider.

AMAIZE is said to seamlessly align with Fieldmade’s deployable additive manufacturing technology. Launched back in 2016, Fieldmade offers fully integrated additive manufacturing systems that are easily deployable, and optimized for military use. Its NOMAD microfactories incorporate a series of military standard mobile units possessing ISO/CSC certified containers, 3D printer cells with environmental control, fully damped 3D printer bases (air, seas, and land transportable), and quality assurance and inspection tools. Powder bed fusion, VAT polymerization, Direct Energy Deposition (DED), and material extrusion 3D printing technologies are all offered by NOMAD.

In the past, FIeldmade has collaborated with the Norwegian Armed Forces and other defense entities. The company has also successfully demonstrated its technology in field exercises and commercial developments in the energy sector.

1000 Kelvin and Fieldmade are confident that this collaboration will enable rapid, high-quality part production at the point of need in all combat environments.

Additive manufacturing on the front lines

Within the global context of growing conflict, additive manufacturing is increasingly being utilized on or near the frontlines to produce parts of consequence. Last year, Australian metal 3D printer manufacturer SPEE3D supplied seven WarpSPEE3D 3D printers to Ukraine, as part of a US Department of Defence’s (DoD) Ukraine Security Assistance initiative.

The company, which specializes in the production of defense-optimized cold-spray 3D printers, also provided a 15-day training program to Ukrainian military personnel. In an interview with 3D Printing Industry, Calum Stewart, SPEE3D’s Director of Defense Programs, stated that SPEE3D technology helps to get “more equipment in the fight, more of the time.”

The mobility of the WarpSPEE3D 3D printers, which are installed within a standard shipping container, makes them especially well suited to combat environments. “You can pick it up, put it on the back of a truck, put it down, set it up, and have it up and running in 45 minutes.” According to Stewart, whilst achievable with cold spray, this level of speed is not possible with laser-based 3D printers.

Similarly, Industrial 3D printer manufacturer Essentium partnered with KVG to provide 3D printing solutions, training, and manufacturing tools to the Ukrainian military. Just 96 hours after approval, Essentium and KVG had successfully deployed a number of advanced High-Speed Extrusion (HSE) 3D printers throughout Ukraine.

The partners stated that the 3D printers will bolster Ukraine’s defense response capabilities by quickly manufacturing a range of mission critical parts at the point of need. Like SPEE3D, Essentium also provided on-site training to ensure continuous and expedited part production.

“In times of conflict, collaboration and agility can create crucial strategic advantages. Our partnership with Essentium is a perfect example. It has allowed us to rapidly deploy essential technology and sustainable mission support tools in Ukraine,” commented KVG President Elisha Abbott.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Fieldmade’s NOMAD micro factory. Photo via Urban Alps.