Voting has now started for the 2023 3D Printing Industry Awards. Cast your vote now!

Industrial 3D printer manufacturer Essentium has partnered with KVG to provide Ukraine with 3D printing solutions, training, and manufacturing tools.

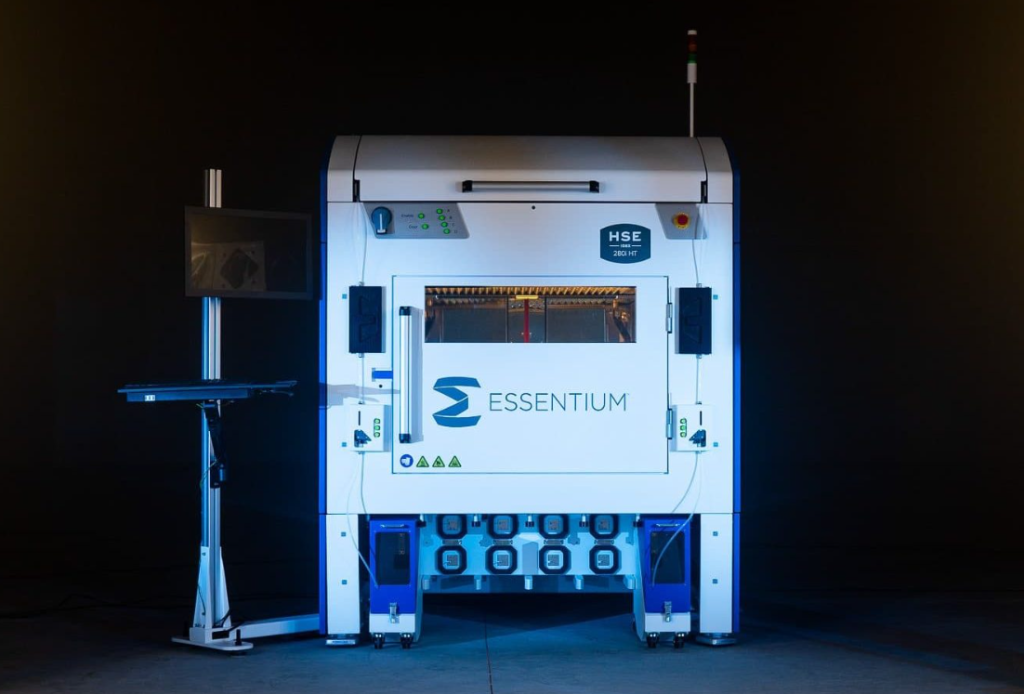

Mission-critical components in conflict zones benefit from rapid on-demand production through 3D printing, says the company. In just 96 hours after approval, Essentium and KVG efficiently deployed advanced High-Speed Extrusion (HSE) 3D printers across multiple locations in Ukraine. These 3D printers are set to boost Ukraine’s defense response capabilities by swiftly manufacturing a diverse range of vital parts, including specialized tools and military hardware replacements. Essential training for the Ukrainian military was also provided on-site to ensure continuous and expedited component production.

Elisha Abbott, President at KVG said, “In times of conflict, collaboration and agility can create crucial strategic advantage. Our partnership with Essentium is a perfect example. It has allowed us to rapidly deploy essential technology and sustainable mission support tools in Ukraine.”

Essentium serving the military

Essentium and KVG are ensuring the direct delivery of 3D printing manufacturing tools to the frontlines in Ukraine. These tools undergo rigorous testing and development on-site to meet the stringent requirements of warfighters, “reflecting the commitment” of the partnership to providing reliable support.

In addition to defense applications, Essentium and KVG are actively developing multiple medical applications using 3D printing technology in conflict zones. Doing so, addresses critical medical needs, highlighting the comprehensive approach of the partnership, which transcends conventional boundaries.

Throughout their involvement in Ukraine, both parties have maintained a cohesive and coordinated response to supply chain challenges. This unified front ensures the effective deployment of resources, resulting in the prompt addressing of critical needs and allowing end-users to maintain operational readiness.

Blake Teipel, Ph.D., CEO of Essentium, said, “KVG’s mission aligns with Essentium’s innovative 3D printing solutions to support the warfighter in challenging locations. This collaboration bridges the gap between 3D printing and traditional manufacturing to allow Ukraine to create vital components in real-time, enhance field effectiveness, and strengthen the warfighter’s capabilities.”

This year started with Essentium reporting that the 101st Air Refueling Wing (ARW), and Maine Air National Guard, are utilizing its HSE 3D printer alongside Essentium PCTG. This combination serves to create training aids for flight control repair, enhancing the proficiency of traditional guardsmen. Opting for Essentium’s 3D printing platform due to its notable speed, precision, and cost-effectiveness, the 101st ARW aims to produce training aids that closely resemble authentic aircraft parts. The expertise of fully trained guardsmen contributes to the extended durability of aircraft components, a reduction in aircraft downtime incidents, and the elimination of safety-of-flight concerns.

Making rapid 3D printing possible for the military sector

As a project of ‘Project TAMPA,’ the UK Ministry of Defence (MoD) aimed to establish a network of suppliers capable of delivering on-demand 3D printed military-grade spare parts. In the pursuit of this objective, the MoD sought to create a multi-supplier framework capable of 3D printing lighter and stronger metal parts exactly when they were needed. The successful implementation of this initiative had the potential to significantly reduce lead times for military equipment and weaponry, while also improving the availability of challenging-to-source obsolete components.

The US Air Force (USAF) invested in a 3D printer capable of creating spare parts for the Strategic Automated Command Control System (SACCS). Faced with the challenge of a supplier discontinuing the production of a red fault indicator lens cap for covering the lights on the SACCS system, the USAF took the initiative to acquire a 3D printer for in-house replacement production. Through the utilization of this technology for the creation of the initial cap, the USAF not only recouped the costs of the printer and scanner but also realized savings exceeding $4,000.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Essentium lent its HSE 3D printers to the Ukraine military. Photo via Essentium.