Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

Australian large-format 3D printer manufacturer AML3D has announced a new prototype Nickel-Aluminium-Bronze (NAB) component order to support the US Navy’s submarine program.

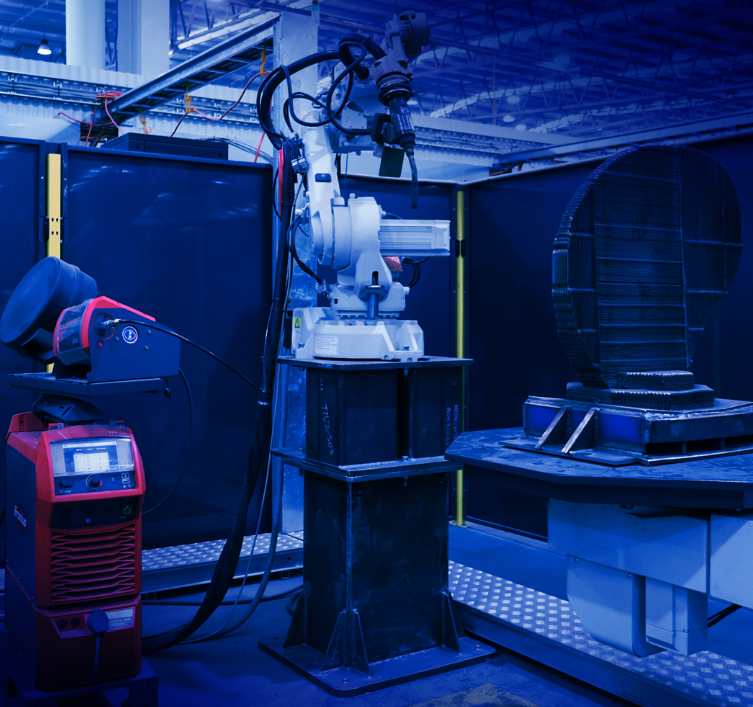

Worth approximately $0.6 million USD, this order is for the production of a prototype part weighing around 1 tonne. This part will be 3D printed using AML3D’s proprietary ARCEMY Wire Arc Additive Manufacturing (WAAM) metal 3D printer.

The order was received by BlueForge Alliance, a nonprofit, neutral integrator. The firm is working to support the strengthening and sustainment of the US Navy’s submarine industrial base, through technology acceleration and adoption.

The manufacturing cycle of the new prototype component is set to run for a period of 22-24 weeks at AML3D’s Adelaide-based facility.

“It is exciting to see this expansion of prototype component manufacturing using AML3D’s proprietary ARCEMY technology to support the US Navy’s submarine industrial base. This order is another opportunity to demonstrate AML3D’s cost effective, high efficiency, high quality, additive manufacturing technology,” commented AML3D Interim CEO Sean Ebert.

“It is also a great opportunity to demonstrate the key role large scale ARCEMY systems can play within the US Defence sector as point of need manufacturing solutions with the potential to solve supply chain challenges for the US Navy.”

AML3D’s ongoing collaboration with the US Navy

According to AML3D, this new order aligns with the company’s ongoing strategy to scale up its operations in the US defense sector. The company hopes to become a point of need, additive manufacturing technology solution to address supply chain constraints within the US Navy’s submarine program. AML3D highlights the US as being the company’s primary growth market.

“AML3D’s US scale up strategy is focused on developing and deepening our long-term, strategic partnership with key stakeholders within the US Navy’s submarine program. Our ability to deliver contract manufacturing solutions that support ARCEMY systems sales into the US Defence sector is an important part of this strategy,” explained Ebert.

The conclusion of the NAB prototype component order follows a recently announced $1.51 million USD contract with the US Navy. This will see AML3D develop and 3D print high-demand, complex, non-safety-critical, replacement NAB components used in US Navy submarines. These components are no longer available through traditional manufacturers.

AML3D is leveraging its ARCEMY 3D printers to produce the parts, which are said to exceed the material strength properties of equivalent cast parts. Starting last month, this contract will run until June 2024.

AML3D has also recently announced a contract extension to continue NAB alloy characterization and strength testing to support the US Navy’s submarine program. This extension builds on the positive results of the company’s initial NAB alloy testing contract signed back in March 2023. Worth around $280,000 USD, this contract extension sees testing take place at AML3D’s facility in Adelaide over a period of 8-10 weeks.

AML3D is also looking to extend its Defense collaborations beyond the US. According to Ebert, “This new NAB prototype component order is also timely in the context of the AUKUS Alliance partnership between Australia, the USA and the UK, and the opportunities AML3D may have to access additional Defense markets over the medium to longer term.”

Metal 3D printing in the US defense industry

Metal 3D printing is certainly a growing area in the defense industry. Earlier this year it was announced that metal 3D printing company Meltio had been recognized as a “strategic technology partner” by the U.S. Department of Defense (DoD) for its metal 3D printers. The company claims that this recognition strengthens its relationship with the US Army, opening opportunities with other US defense departments and armies around the world.

Elsewhere, a Xerox metal 3D printer was installed on the USS Essex last year. Since this installation, the Wasp-class amphibious assault ship has served as a test bed to evaluate the performance of the 3D printer on the open sea.

This project has seen sailors trained on how to use the 3D printer, as well as a sea testing program. This program involves a USS Essex-based team 3D printing a variety of aluminum parts, and reporting results back to NPS and Commander, Naval Air Force, U.S. Pacific Fleet (COMNAVSURFPAC).

“Having this printer aboard will essentially accelerate, enhance and increase our warfighting readiness. The capabilities of the 3D printer will enable Essex to become more self-sufficient,” commented Lt. Cmdr. Nicolas Batista, the Aircraft Intermediate Maintenance Department (AIMD) officer of the Essex.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a typical ARCEMY metal 3D printing system. Photo via AML3D.