Industrial 3D printer manufacturer Essentium has announced that the 101st Air Refueling Wing (ARW), Maine Air National Guard are using the Essentium High-Speed Extrusion (HSE) 3D Printing Platform and Essentium PCTG for printed flight control repair training aids to help maintain proficiency for traditional guardsmen.

To create training aids resembling genuine parts, the 101st ARW chose Essentium’s 3D Printing Platform for its speed, accuracy, and low-cost materials. The fully trained guardsmen help increase the lifespan of aircraft parts, reduce instances of downed aircraft, and eliminate safety of flight issues.

“This valuable tool has also caught the attention of other local military components, such as the Maine Army National Guard, who began requesting similar training aids for their rotary aircraft. We’re excited that the Essentium HSE is currently being used as a cross-functional force multiplier that can shape the future of readiness across the joint force,” said Blake Teipel, Ph.D., CEO, of Essentium.

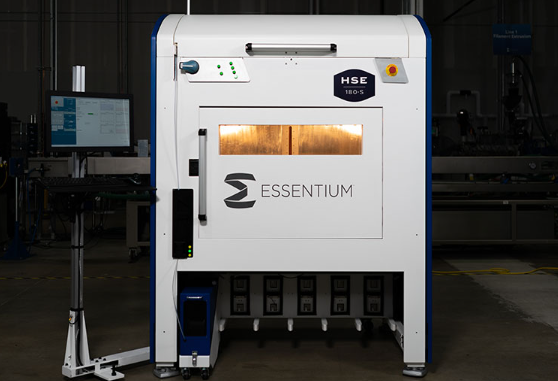

Why the engineers chose Essentium HSE 180 ST 3D printer?

Engineers at the 101st ARW developed a training aid for the outboard aileron balance tab in one weekend using the Essentium HSE 180 ST 3D Printer. This is a crucial flight control aspect with aircraft attachment points that wear out frequently. Guardsmen machine new holes, install bushings, inspect for accuracy, and install them to restore the outboard aileron balance tab to factory specifications. Spare aileron balance tabs, on the other hand, are scarce and typically reserved for in-flight repairs. These parts are challenging to maintain when combined with the challenges of retaining experienced professionals in aileron balance tabs, says the company.

A faulty repair can permanently damage an aircraft part, necessitating its replacement. If the part is not immediately available, the aircraft may crash. In the worst-case scenario, if the part is not fixed correctly and causes a safety-of-flight issue, the aircraft may be lost.

The part must retain its dimension when aluminum components are pressed into it to be an effective training aid. The 101st ARW engineers chose Essentium PCTG because of its low cost, ideal surface finish, and impact strength. The 101st ARW now has quick and repeatable access to these rare parts thanks to the Essentium HSE 180 ST 3D Printer and Essentium PCTG.

Guardsmen can utilize technical data that applies to the part to repair it employing the Essentium HSE’s scale model of the part, just as they would with the actual part.

“For this application, we chose Essentium over other printers because it can print faster and more accurately with external dimensions. The material cost is also relatively less,” said Master Sgt. Jason Howes. “You can’t put a value on having proficiently trained guardsmen. The confidence they get from putting their hands on the product, understanding what the result will look like, and gaining muscle memory is simply invaluable.”

Strengthening the defense sector with additive manufacturing

Previously, Australian 3D metal printing company AML3D, and BAE Systems, a British multinational arms company, announced a prototyping purchase agreement with BAE Systems Australia. The agreement will aid BAE Systems Australia’s contract to manufacture nine Hunter class frigates by researching the viability and prototyping of parts. The prototype components will help BAE Systems Australia fulfill its deal with the Australian Department of Defence to design and build nine Hunter class frigates for the Royal Australian Navy.

Furthermore, the UK Ministry of Defence (MoD) was looking to build a supplier network competent in 3D printing military-grade spare parts on demand. As part of ‘Project TAMPA,’ the MoD aimed to build a multi-supplier framework capable of 3D printing lighter, stronger metal parts as needed. If this is accomplished, the UK government department expects to reduce lead times for military equipment and weaponry while enhancing the availability of difficult-to-source obsolete parts.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows Essentium and Maine National Air Guard representatives. Image via Essentium.