UK-based 3D printer reseller EVO 3D has announced a significant expansion of its EVO TECH 3D Robot Printing Cell range.

Launched last year, EVO 3D’s pellet 3D printing packages allow users to deploy various robot, extruder, and software combinations, to achieve high throughputs and production at scale. Following up on the initial offering it built with robot manufacturer KUKA, robotic 3D printing software developer Ai Build, and Canadian OEM Dyze Design, the firm has now announced new partners: ADAXIS and REV3RD.

According to EVO 3D, the French-Swedish robotics software company and large-scale 3D printing start-up “have been carefully selected” to add their products to its already-robust EVO TECH 3D Robot Printing Cell lineup.

EVO 3D’s additive manufacturing portfolio

EVO 3D aims to set itself apart from the crowd by offering a full 360 solution to customers’ needs. The company aims to achieve this by offering impartial advice and technical support to its clientele, something it says is vital to ensuring they fully realize the potential of purchases within their projects.

So far, EVO 3D’s approach has seen it attract customers such as the National Manufacturing Institute of Scotland, the University of Cambridge, and the London Electric Vehicle Company. Between them, these organizations have leveraged the firm’s services to address applications varying from research to the industrial and automotive sectors.

Since launching in 2021, EVO 3D has rasied £250,000 towards its expansion, and it was later announced that EVO3D would join with Evolution Sales and Marketing, in a move designed to strengthen its 3D printing offering, particularly within the automotive, aerospace, industrial, and prototyping markets.

Launching into the world of robotics

Generally speaking, pellet 3D printing offers a number of advantages over filament-based alternatives, as they unlock higher throughputs and access to a wider range of polymers, as well as reduced material costs. In fact, depending on the amount used, pellets can cost anywhere from 65-90% less than filaments made from the same plastic.

Aiming to provide its customers with greater access to these benefits, EVO 3D launched its robotic pellet 3D printing service in April 2022. Behind this offering was a suite of systems developed alongside KUKA, Ai Build and Dyze, with large powder-coated build plates of varying sizes, upon which pelletized feedstock could be extruded at high speed.

At launch, it was said that the large heat zones of the machines’ pellet extruders, provided them with a throughput almost 100 times greater than that of average Fused Deposition Modeling (FDM) 3D printers. Through the combination of different pellets, and the addition of dyes, additives, and reinforcement fibers, customers were also able to create custom composite plastics, including those with eco-friendly recycled content.

A growing robotic 3D printing offering

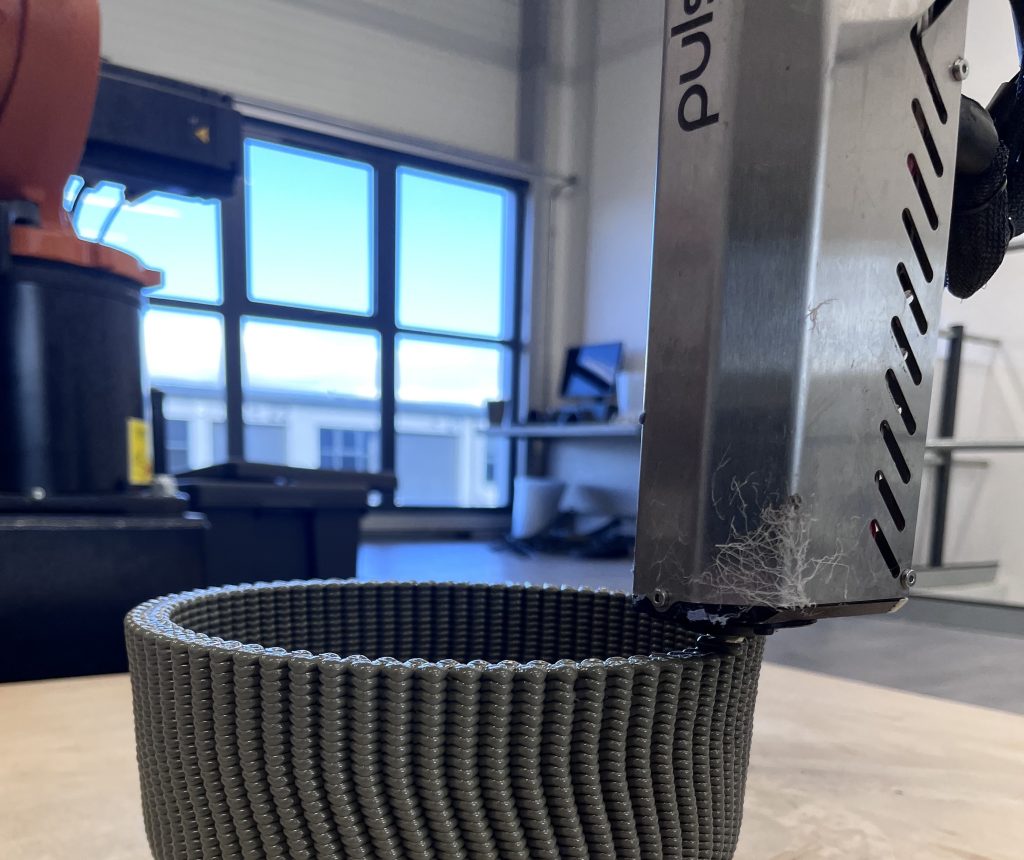

Since the launch of its initial robotic pellet 3D printing packages, EVO 3D has been hard at work, both building out its business and putting its offering into action. As well as moving into a new facility, complete with a large additive manufacturing demonstration suite in Exeter, the firm has begun selling the Long Arm Pulsar edition of its robotic system, with its first customer being the Chemnitz University of Technology.

In order to build on its automated pellet 3D printing offering, EVO 3D has also partnered with ADAXIS and REV3RD. The former is best known as the developer of a software that makes it easier for robotics users to configure their machinery for 3D printing. Compatible with brands like KUKA, ABB and Fanuc, the company’s AdaOne platform offers simulation and multi-axis path planning functionalities.

REV3RD, on the other hand, specializes in the 3D printing of large-scale structures from recycled materials. In its efforts to optimize this process, the firm has developed its own 3D printers, which use industrial CNC motion control systems and servo drives on all axes, to increase their speed and reliability. REV3RD also markets high-throughput pellet extruders with outputs as high as 40 kilos per hour.

Working with its new partners, EVO 3D has been able to expand its robotic pellet 3D printing offering. At launch, the firm brought its Small but Mighty, Long Arm and Long Arm Heavy products to market. However, these have now been superseded by its Long Arm Pulsar, Extended Arm REV3RD, Strong Arm REV3RD, and Sliding Arm CEAD editions.

Fitted with Dyze, REV3RD and CEAD extruders respectively, each of these features a different capacity and extrusion rate, allowing customers to choose that which suits their project needs. For instance, the 1,000mm3 Long Arm Pulsar edition can extrude materials at a pace of up to 2.5 kilos per hour, but the slightly larger Strong Arm REV3RD edition can hit much higher speeds of 25 kilos an hour.

The systems are available at prices ranging from £75,000 to £190,000. For more information or a more precise quote, prospective customers can contact EVO 3D directly here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows EVO 3D’s EVO TECH 3D Robot Printing Cell. Photo via EVO 3D.