The US Air Force (USAF) has invested in a 3D printer capable of producing spare parts for its Strategic Automated Command Control System (SACCS).

When a supplier stopped manufacturing a red fault indicator lens cap to cover the lights on the SACCS system, the USAF purchased a 3D printer to manufacture its own replacement. By leveraging the technology to produce the first cap, the USAF recovered the cost of the printer and scanner and saved more than $4,000.

“This strategy is saving the Department of Defense thousands of dollars each time the part fails,” said Col. Brian Golden, National Airborne Operations Center and 595th Command and Control Group Commander.

The Air Force’s use of 3D printing

The USAF has leveraged additive manufacturing for some time across a variety of applications and projects. Back in 2020, engineers from the Air Force Sustainment Center became the first to test a 3D printed metal component inside a USAF aircraft engine.

Since then, the USAF has filed a patent application for a novel 3D printed nose simulator, has enlisted circuit board fabrication specialist BotFactory to develop a fully-automated desktop electronics 3D printer as part of its ‘AFWERX’ program, and has awarded 3D printer manufacturer Optomec with a $500,000 contract to develop optimized 3D printing process parameters to repair its fighter jet engine turbine blades.

More recently, the USAF has awarded aerospace firm Boom Supersonic with a $60 million contract to accelerate the R&D of its upcoming ‘Overture’ supersonic flight-capable aircraft, and has funded the advancement of 3D printing specialist Senvol’s machine learning technology to drive forward the qualification of new aerospace 3D printing materials.

Solving maintenance issues with AM

For its latest 3D printing-focused project, the 595th Strategic Communications Squadron of the USAF, which operates the SACCS, has leveraged the technology to improve its maintenance of the system.

The SACCS provides rapid re-targeting of ICBMs, force distribution and emergency action messaging capabilities, and operates sole depot repair authority across 252 global sites. Operating 24/7, the SACCS processes more than 84 million US Strategic Command messages each year.

The machine itself is 70 years old, and as such some of its parts are becoming obsolete. When the supplier of the SACCS’ red fault indicator lens cap discontinued manufacturing the part, the squadron purchased a 3D printer that would enable it to reverse engineer and produce its own replacement.

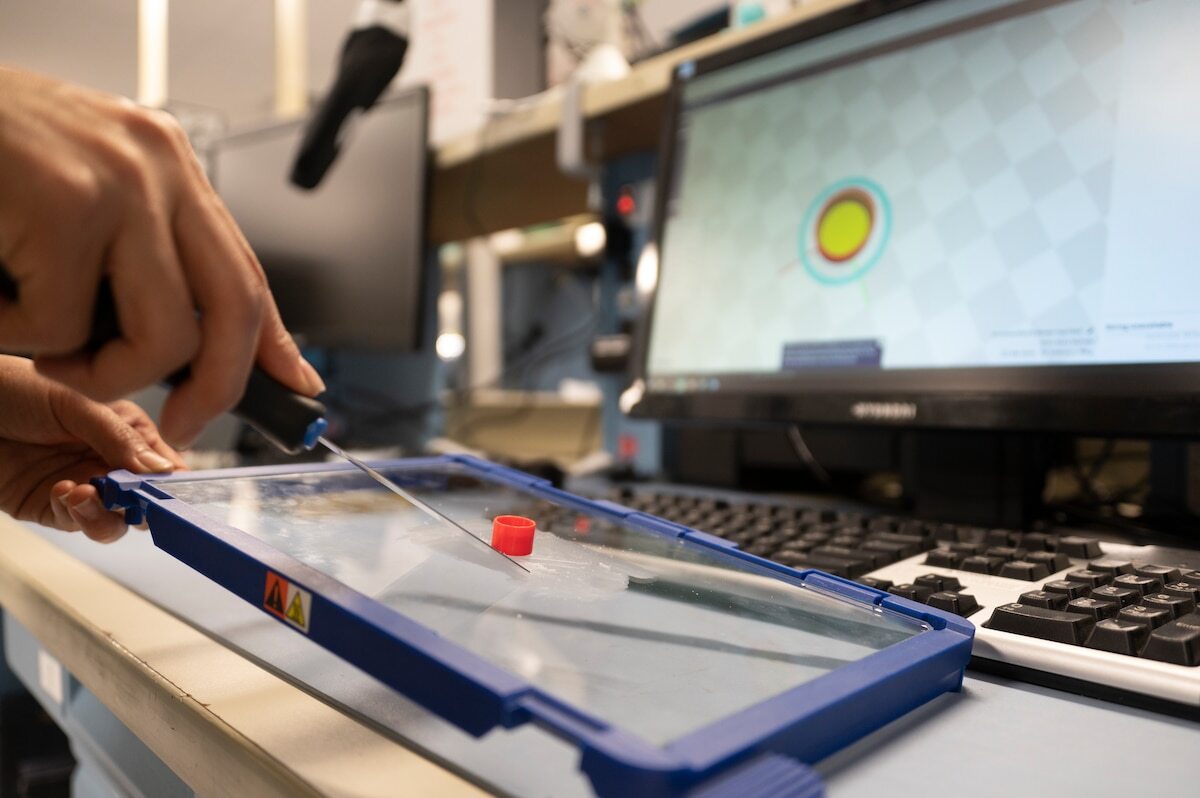

Beginning with a trial and error approach, the team worked to configure the necessary design and dimensions of the lens cap via 3D scanning, before achieving the desired part. They then saved the process to allow the easy and quick fabrication of lens caps in the future.

Previously, the only way to repair the fault indicator on a SACCS system blower was to replace the entire component at a hefty cost of $7,187. However, after the first 3D printed cap was produced, the squadron not only recovered the outlay costs of the 3D printer and scanner, but also saved a total of $4,475.

Going forwards, the USAF expects the 3D printer to save “thousands of dollars” in repair and supply chain costs in the future.

“The 3D printer is just another example of how the dedicated and innovative airmen of the 595 SCS continue to find ways to sustain and operate legacy SACCS until the system can be modernized under the phased approach of the SACCS-Replacement program,” said Golden.

“We are going to have to come to the realization soon that this type of replacement process is paramount to keep legacy NC3 systems in the game for years to come.”

Now that the proposal has been approved by the Air Force Global Strike Command, the squadron is working to get a stock number assigned to for the lens cap and enter it into the supply system, eventually enabling other USAF units to request the lens caps directly from the 595th Centralized Repair Facility (CRF).

Going forward, the unit plans to deploy the 3D printer to model and produce similar legacy components that are no longer in the USAF’s supply system. The USAF will also expand the technology’s use to support the repair of other assets within the 595th Command and Control Group.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows a network technician for the 595th SCS constructs a cover for an alert light with a 3D printer at Offut Air Base. Photo via USAF.