The U.S. Air Force (USAF) has contracted circuit board fabrication specialist BotFactory to develop a fully-automated desktop electronics 3D printer.

Enlisted as part of the USAF’s ‘AFWERX’ program, BotFactory’s engineers are building a system that’s capable of 3D printing and assembling Printed Circuit Boards (PCBs) on-site and on-demand. By manufacturing PCBs in-house, the USAF stands to save millions of dollars each year in procurement costs, in addition to achieving drastically reduced lead times within its aerospace prototyping process.

The USAF’s ‘AFWERX’ initiative

BotFactory has been commissioned to develop its prototype PCB 3D printer as part of the broader AFWERX program. Backed by the USAF, the initiative is designed to establish technology, talent, and transition partnerships with private firms, that improve the speed and affordability of the agency’s deployment capabilities.

Broadly, the scheme is split across three main areas, codenamed ‘Spark,’ ‘Prime’ and ‘AFVentures,’ the latter of which focuses on using military problems to accelerate tech commercialization. Essentially, by issuing STTR/SBIR contracts to emerging start-ups, the U.S. Space and Air Forces aim to become early-stage ‘investors,’ that help accelerate their technologies’ time to market.

So far, the program has seen a total of $710 million in funding issued to companies, with 99 of these being either 3D printing-focused or developing advanced materials. Additionally, of the 1,433 firms in the AFVentures portfolio and the 2299 that have been contracted, only 43 relate to electronics, making BotFactory’s system fairly unique within the wider AFWERX framework.

“Next-gen” electronics 3D printing

Over the next 15 months, BotFactory is set to work with engineers from the 402th ‘EMXG/MXDEK/REARM’ Lab at the Robins Air Force Base (AFB), to develop a prototype PCB printer. At present, the Robins team focuses on reverse engineering legacy systems, but fabricating and assembling electronics has remained a bottleneck.

In order to expedite the reverse engineering process, BotFactory has proposed a “next gen” electronics 3D printer, in which an AI program automatically monitors PCB fabrication and assembly. While the firm hasn’t released exact details about how the machine will function, it’s understood to be based on an inkjet 3D printing technology, in which a solder paste is dispensed layer-by-layer to form circuitry.

Having the ability to print PCBs on-demand, could enable airmen to more rapidly prototype experimental designs, or to reverse engineer components that optimize the MRO of existing flight hardware. What’s more, given the wider scarcity of PCBs, and President Biden’s recent executive order on the domestic sourcing of electronic devices, the firm’s technology could also have wider applications in future.

Towards the end of the $750,000 project, BotFactory is set to put the capabilities of its machine to the test, by prototyping through-hole components before conducting a field test with USAF colleagues. Once the team’s field testing feedback has been implemented, the novel system will pass onto its final developmental stage or ‘phase III.’

According to BotFactory’s Co-Founder and CTO Carlos Ospina, the firm’s technology is unlike anything else that’s currently being developed. “Integrating inkjet printing and pick-and-place capabilities for PCB fabrication is something no-one is doing, and we’re excited to work with the USAF to fix a problem that is so critical to U.S. national security.”

An emerging PCB market

Although the market for functional 3D printed PCBs remains at an embryonic stage, Israeli company Nano Dimension has emerged as one of its early leaders. Using its proprietary DragonFly LDM system, the firm is capable of 3D printing multi-layered circuitry, and it recently worked with L3Harris to launch additive RF circuits to the ISS.

Precision micro dispenser manufacturer, nScrypt, has also made progress with its Smartpump electronic 3D printing technology recently, by depositing solder dots in the 50-micron range for the first time. The advance means that the process can now be used to print directly onto flat and irregularly-shaped circuit boards.

Elsewhere, the US-based Nextflex consortium has entered into a cost-sharing agreement with the Air Force Research Laboratory (AFRL). The arrangement will see the U.S. Department of Defense (DoD) providing up to $154m in funding, with the aim of developing 3D printed electronics for defense applications.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

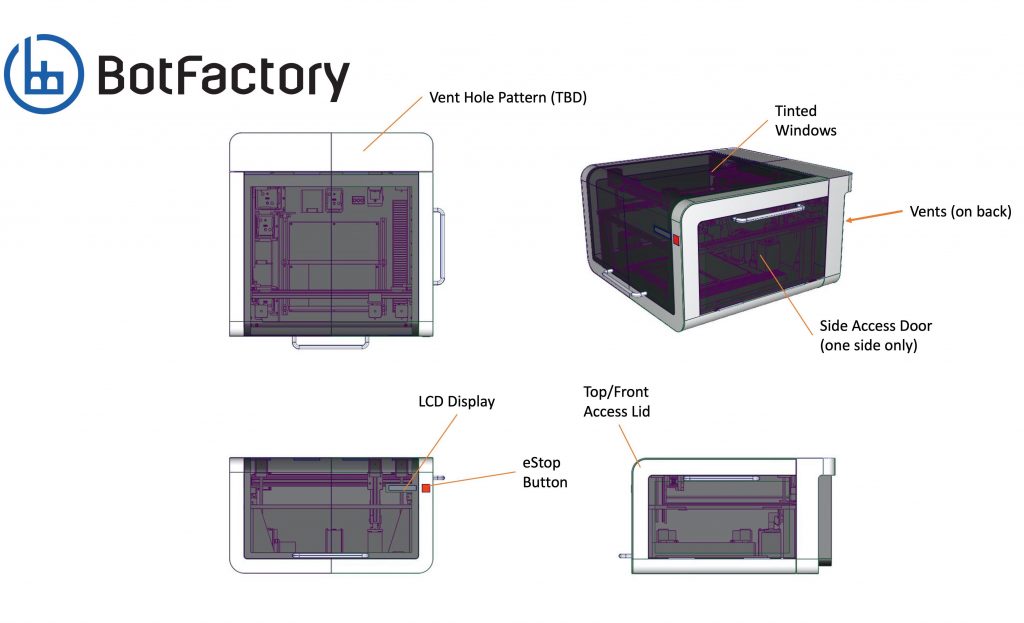

Featured image shows a breakdown of BotFactory’s proposed electronics 3D printer. Image via BotFactory.