Minnesota-based 3D printer manufacturer Evolve Additive Solutions has announced the commercialization of STEP Parts Now, a new parts production service designed to scale additive manufacturing to meet demands in serial production. The company also introduced two new materials into its portfolio: Nylon PA-11(A) and Gray ABS.

Evolve’s new offerings were unveiled at Formnext 2023 during a press conference headed by Evolve President and COO Jeff Blank, Jeff Hansen, SVP of Go-to-Market, and Melissa Hanson, VP Marketing.

Follow the full coverage of Formnext 2023.

STEP Parts Now further enhances Evolve’s part ordering service through the company’s strategic partners and STEP production centers.

Evolve recently announced a strategic partnership with German 3D printing service provider alphacam GmbH, who now offer Thermoplastic Electrophotographic (STEP)-manufactured parts as a service to customers in Europe. On-demand manufacturing service provider Fathom Digital Manufacturing also runs a STEP production center, providing Evolve’s 3D printing serial production capabilities to customers in the US.

“We’re not selling a prototyping system, so we’re unique in the targets that we’re going after. And that’s really in the injection molding space,” explained Jeff Hanson. “Fathom’s customers are starting to migrate and leverage this technology as a bridge to production, in some cases for end use parts.”

Jeff Hanson added that this new offering enables a shift from prototyping to production. “Our customers would come in for prototypes and then they would go away. But with Step Parts Now we can develop their application, go through their prototype iterations, and just keep hitting the print button to go to production.”

“It’s finally delivering on the promises that additive has made to the industry for the last 30 years.”

Scaling production with STEP Parts Now

Launched back in 2017, STEP 3D printing technology enables high speed 3D printing of engineering-grade thermoplastics 50 times faster than SLS 3D printing, enabling a shorter time to market with “toolless” production.

The electrophotography-based additive manufacturing (EPSD) process employs electrophotographic imaging and deposition. Here, material is deposited layer by layer via a moving belt, until the desired part has been 3D printed.

According to Evolve, STEP is the only additive manufacturing technology on the market capable of delivering the fidelity, surface finish, accuracy, and material properties needed to reliably and repeatedly 3D print end-use parts at scale.

Customers can now quote and order STEP 3D printed parts directly from Evolve through the STEP Parts Now e-commerce portal. This portal reportedly allows for greater application development, expanding serial-3D printing production for more use cases.

“The core of Step Parts Now is accessibility and application development,” commented Jeff Hanson. “The core of this model is talking to the customers, seeing their geometries, talking to them about their manufacturing process and their constraints with those processes, and then working with them through design for additive manufacturing, turning those into production applications.”

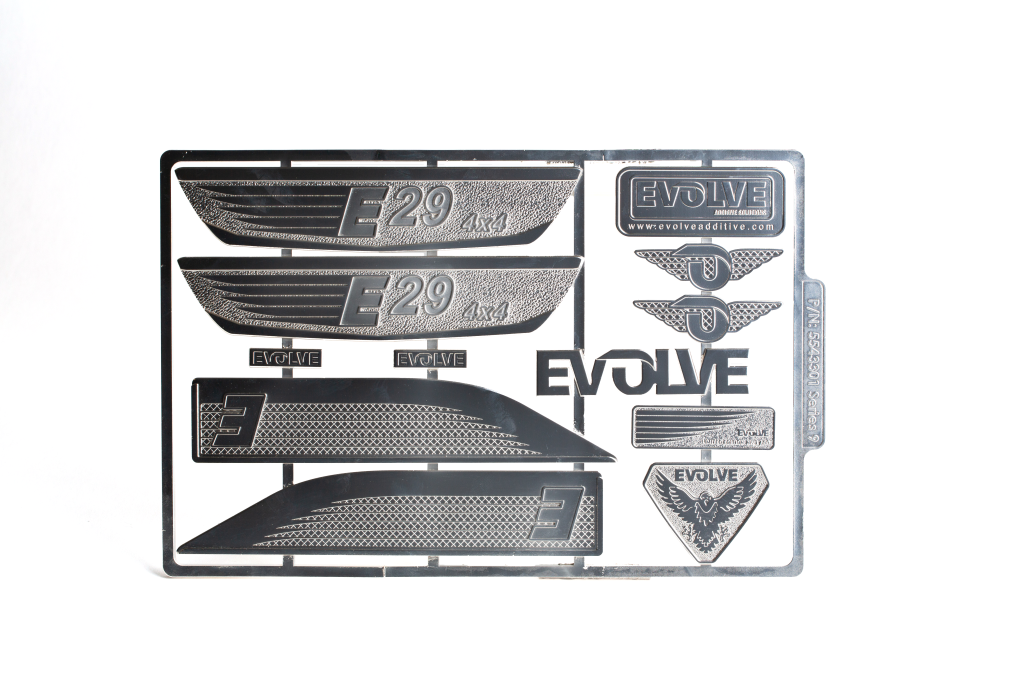

Evolve’s STEP offering has already attracted interest for large scale, serial production runs. Jeff Hanson outlined one unnamed automotive company as quoting the production of 40 unique badges. The company is said to be looking to produce 100,000 of each unique badge, taking the total number to 4 million printed parts. Jeff Blank also pointed to the electrical wearables, consumer goods, and medical industries as requiring large production runs.

The cost and time savings of STEP are said to be substantial. For instance, 736 car fender brackets can reportedly be 3D printed in 6.5 hours. Additionally, Evolve has 3D printed 40 LED screen components for visual display manufacturer Daktronics at $83 per piece, compared to $10,000 apiece using injection molding.

Evolve’s growing material portfolio

Evolve’s new PA-11(A) has been optimized for STEP, and reportedly offers significant mechanical performance advantages over powder bed fusion PA-11. For instance, this new material offers superior elongation at break, higher impact strength, and a higher heat deflection temperature (HDT). As such, PA-11(A) STEP 3D printed parts are suited to a range of demanding production applications.

A new Gray ABS material has also been launched, complementing Evolve’s existing Black ABS. This new material is said to exhibit mechanical properties within 10% of bulk injection molded ABS, whilst possessing structural color contrast for fine textures.

Evolve also told 3D Printing Industry that it is developing new multi-material capabilities, allowing for parts to be 3D printed possessing multiple colors and material properties in a single build. This offering is not yet commercially available, but Evolve has already demonstrated the capability in a number of sample 3D prints.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Evolve Additive Solutions STEP manufactring floor. Photo via Evolve Additive Solutions.