Swedish 3D printer manufacturer Freemelt has been granted patents for a novel approach to post-processing that allows excess powder to be ‘frozen’ out of complex parts.

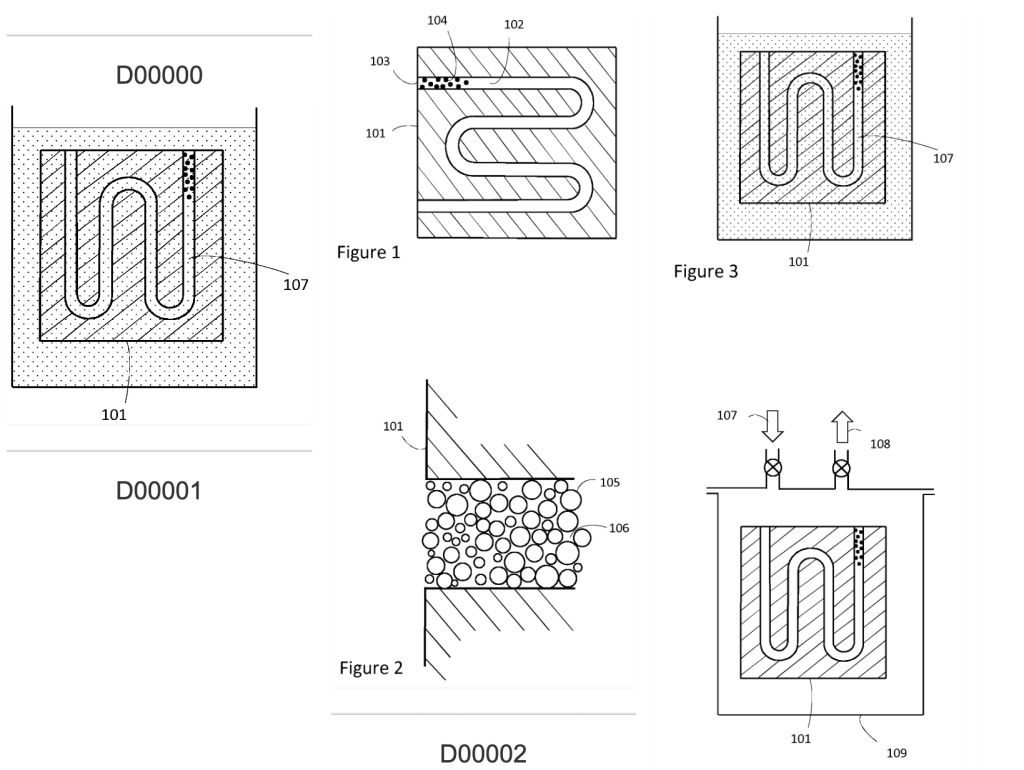

Designed for finishing powder bed fusion printed parts, the process involves filling them with saline water, which is then frozen in a way that breaks the links between powder grains stuck in their internal channels, making any excess easier to eject.

It’s thought that the technology, which is now patented in the US and Europe, could soon enable 3D printing to be used in a wider range of applications, particularly in the creation of gas turbine components with intricate internal features.

“This innovation increases the opportunities to use 3D printing technology in more application areas and can increase the competitiveness of our customers,” explains Ulric Ljungblad, Co-founder and CEO of Freemelt. “Examples of this are heat exchangers that often have a lot of cavities that are difficult to access.”

Freemelt’s metal 3D printing mission

Since it was established five years ago, Freemelt has been on a mission to advance the development of materials for use within metal 3D printing. In large part, the firm has sought to achieve this via the Freemelt ONE, an electron beam machine (EBM) with a vacuum chamber, recoating mechanism and adaptable powder feeding system, that’s said to be ideal for engaging in advanced metal powder R&D.

Already, the 3D printer has already been installed at numerous research facilities. In June, Freemelt received its first Slovenian order via the University of Maribor, which intends to use the system as a means of identifying orthopedic implant materials.

The company also continues to advance the capabilities of the Freemelt ONE through its own internal R&D programs. Back in September 2020, Freemelt came up with ‘ProHeat,’ a novel method of preheating the powder bed. Since then, the 3D printer developer has also launched its Pixelmelt process optimization tool, which enables users to modify parameters across several parts in a single build.

Freezing out excess materials

As outlined in Freemelt’s newly-granted US and European patents, its novel post-processing approach is designed to address the issues that currently surround the finishing of parts with complex internals. Specifically, the firm says that when 3D printed, these components can be left with residual powder inside them, either due to semi-sintering, a binder holding grains together or friction-induced interlocking.

While many approaches to clearing excess material exist, including the use of rotating tools and ultrasonic methods to separate and flush out powder particles, Freemelt’s patents outline an alternative that relies on “thermal shock” instead.

The company claims that freezing water pumped into the channels of such parts, makes it expand by 10%, in a way that effectively “breaks the forces holding powder grains together.” In addition to making unwanted materials easier to remove, this phase change is said to be repeatable. As such, the patents claim cycled phase transformations can allow pressure to be built up to clear stubborn blockages.

Moving forwards, Freemelt’s patents say that removing dissolved gas from the water used to fill parts “may be advantageous,” in that it would reduce the risk of ‘pockets’ forming inside cavities which aren’t affected by thermal shock. In the documents, the firm also suggests that post-freezing, powders can be removed in various ways, with ultrasonic methods achieving “efficient energy transfer.”

As with many patents, Freemelt’s are quite broad in their application, covering the finishing of parts with one or more internal cavities and “at least one external opening,” that have excess cleared via a “phase transition from liquid to solid phases.” In particular though, the documents outline its potential as a means of treating gas turbine parts, the likes of which tend to have narrow cooling channels.

For those interested, Freemelt’s USPTO patent and Freemelt’s European patent office patent can be viewed via the websites of either organization under the title ‘Freezing method for cleaning an additive manufacturing part.’

Fast-tracking the finishing process

Though often necessary in preparing 3D printed parts for end-usage, post-processing is regularly cited as a ‘bottleneck’ slowing down their production, and preventing their mass manufacture. As such, a significant amount of research continues to be conducted into accelerating the process, some of which has yielded component finishing innovations that have already made it to market.

LuxYours, for instance, was granted a patent for its Iterative Flux Smoothing process back in 2020, which it has since been integrated into its LUXMatic700 systems. By liquifying the outer layer of 3D printed parts, before allowing it to re-form with a high level of surface finish, the technology is said to yield stronger products that don’t develop loose particles or feature soiling, making them much easier to clean.

Additive Manufacturing Technologies (AMT) has also partnered with Japanese electronics manufacturer Mitsubishi Electric to develop a fully-automated post-processing machine for plastic parts. Effectively a combination of the PostPro3D and Mitsubishi’s articulated arm robots, the system is designed to significantly increase productivity, from a few parts finished per hour up to hundreds.

Elsewhere, in ceramic 3D printing, XJet has launched its Support Material Automatic Removal Technology or ‘SMART’ post-processing station. Marketed as the ‘last link in the chain’ for automated end-to-end 3D printing, the SMART unit uses intelligent algorithms to automatically remove supports, thus freeing up engineers to go and spend their time on more value-generating activities.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram from Freemelt’s patents indicating how its new post-processing technology works. Image via Freemelt, the USPTO.