The US’ largest 3D printing event made a return this week, with over 400 exhibitors showcasing the latest 3D printers, software, materials, and hardware. With the RAPID + TCT show now well underway at Huntington Place, Detroit, there’s already been a whole slew of developments regarding 3D printing software.

Materialise showcased the latest iteration of its flagship print preparation program, Dyndrite has signed several new software partnerships, and Freemelt has debuted its new Pixelmelt process optimization software.

Read on for the latest RAPID + TCT 2022 news from Materialise, Dyndrite, and Freemelt.

Materialise introduces Magics 26

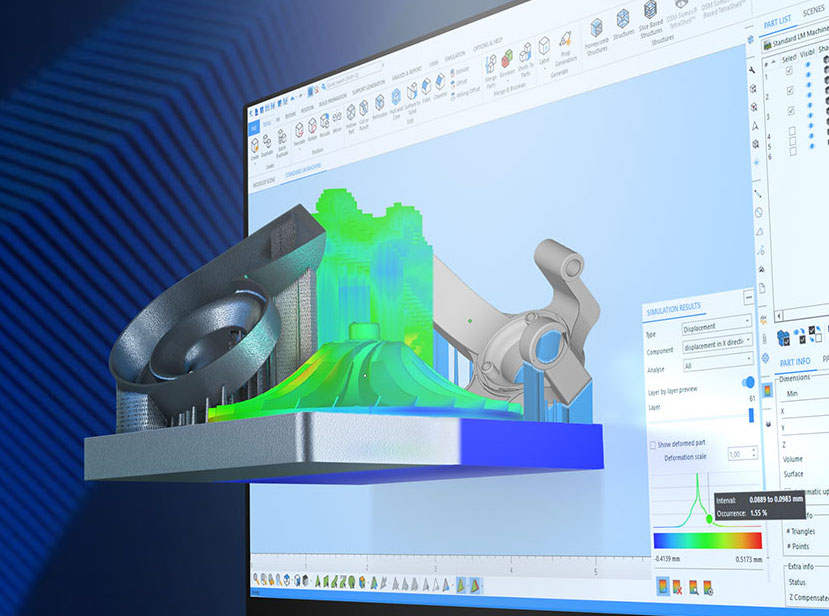

Leading additive manufacturing software developer Materialise has showcased Magics 26 on the show floor, the latest version of the firm’s widely-used print preparation software.

The big upgrade here is the addition of native CAD-based workflow support, which enables users to modify and iterate on CAD files directly in Magics. Prior to the update, users could only work with conventional mesh-based 3D file formats like STL. Each of the file types offer their own benefits as CAD lends itself to higher resolutions while editing parts, but mesh provides a reliable format that’s guaranteed to be compatible with all 3D printers.

The integration of native CAD support is expected to benefit those that frequently switch between part design and build preparation. Saving parts in a CAD file format saves time when redesigning a component, while also ensuring improved geometric integrity.

“The way forward is to combine mesh and CAD for data preparation in 3D printing,” said Egwin Bovyn, Materialise Product Line Manager. “Mesh-based processes hold significant benefits for applications and operations in data and build preparation with current 3D printing technologies. Introducing CAD-based workflows in Magics 26 creates a path toward enhanced hybrid workflows in future versions of our software.”

Dyndrite signs three new software partnerships

3D printing software developer Dyndrite has signed three new partnerships with 3D printer OEMs Azul 3D and Impossible Objects, as well as printhead tech provider Meteor Inkjet.

Azul 3D will integrate Dyndrite’s application development kit (ADK) into its LAKE 3D printing systems, which are based on Azul’s High Are Rapid Printing (HARP) technology. Specifically, the firms will work together to develop a series of custom software applications to enable better image generation, build compensations, and other features such as build automation. The upgrades, planned for launch later this year, are intended to increase productivity on the LAKE printers while improving build quality for industrial applications.

Similarly, Impossible Objects has chosen to work with Dyndrite’s ADK to power its own composite-based additive manufacturing (CBAM) systems. Using the firm’s purpose-built geometry engine, Impossible Objects was able to create an early-stage automated print preparation workflow that vastly improved build times by slashing the need for manual human intervention.

“Committing to Dyndrite software was an easy choice to make at this point,” said Robert Swartz, CEO of Impossible Objects. “Two weeks into our initial project, manual build prep went from three hours down to a few minutes as we automated with the Dyndrite tools. 3D data processing benchmarks dropped from 56 minutes to 5 minutes, so that the entire four-hour process is now completed in less than 10 minutes, a 95% reduction in time.”

Finally, Meteor Inkjet has expanded its partnership with Dyndrite with the development of Meteoryte. The new software tool is aimed at 3D printer manufacturers looking to integrate inkjet printheads into their systems, and provides a set of toolkits that streamline product development. Using Meteoryte, machine builders can easily import ready-made functionality such as 3D mesh and geometry manipulation, a viewport for part visualization, and build slicing up to resolutions of 1200dpi.

Freemelt launches its Pixelmelt software

Freemelt, a developer of electron beam melting (EBM) 3D printers, has announced its new Pixelmelt software. Set to launch in Q3 2022, the process optimization tool is designed to initially be used with the firm’s Freemelt ONE research system and enables users to modify the process parameters across several parts in a single build.

Ulric Ljungblad, CEO of Freemelt, said, “A laser-based 3D printer can scan the beam at around 10 meters per second. Freemelt’s proprietary electron beam can move the beam 4,000 meters per second, several hundred times faster than a laser beam. This means that the beam can jump between tens of thousands of melting points every second and distribute the heat in an optimal way.”

Using Pixelmelt, Freemelt customers will also now be able to melt their powder materials in free spot patterns over a surface rather than along parallel lines, paving the way for improved productivity.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Freemelt’s ProHeat electron beam powder bed fusion preheating technology in progress. Image via Freemelt.