LuxYours, a manufacturer of post-processing systems for 3D printed parts, has successfully obtained a patent for its proprietary Iterative Flux Smoothing (IFS) technology.

The basic patent, which was filed in March 2018, covers the company’s novel IFS technique, along with its upcoming post-processing machines. LuxYours’ process combines several chambers to form a closed volume, where 3D printed parts can be pre-conditioned separately and smoothed together. The firm’s IFS technology has been integrated into its newly-launched LUXMatic700 systems, which are currently being shipped out to customers.

“We are now supplying our most loyal customers with the first LUXMatic 700s,” said Florian Pfefferkorn, Managing Director of LuxYours. “These customers have been with us since our foundation in January 2017, and with their machine purchases in December 2018, they showed great confidence in our capabilities. We are all very pleased to be able to confirm the confidence placed in us.”

Patenting LuxYours’ Iterative Flux Smoothing technology

Established in 2017 and based in Munich, LuxYours specializes in the post-processing of 3D printed parts. Leveraging its proprietary IFS technology, the company offers chemical smoothing as a service, helping clients to get the best surface finish from industrial, medical, and lifestyle products.

The IFS process works by effectively liquifying the outer layer of 3D printed plastic parts, before allowing it to re-form with a high level of surface finish. Post-processed components are reportedly stronger than the original part, don’t develop loose particles, and feature reduced soiling, making them easy to clean.

Although IFS is compatible with a range of polymers, it’s particularly well-suited to those made of polyamide, TPU, PEBA, PLA, and PET. For optimal performance with LuxYours’ patented process, components should have wall thicknesses wider than 1mm and not have any moving parts. IFS can also be carried out repeatedly, allowing the macroscopic smoothing of surface textures, albeit at the expense of a part’s more detailed features.

The company’s newly-obtained patent covers “a process and a device to be used for this purpose,” including that used in its LUXMatic 700 machines, which began shipping in July 2020. Having successfully patented its technology, LuxYours will now be able to develop future iterations of IFS, safe in the knowledge that the process cannot be legally replicated by others.

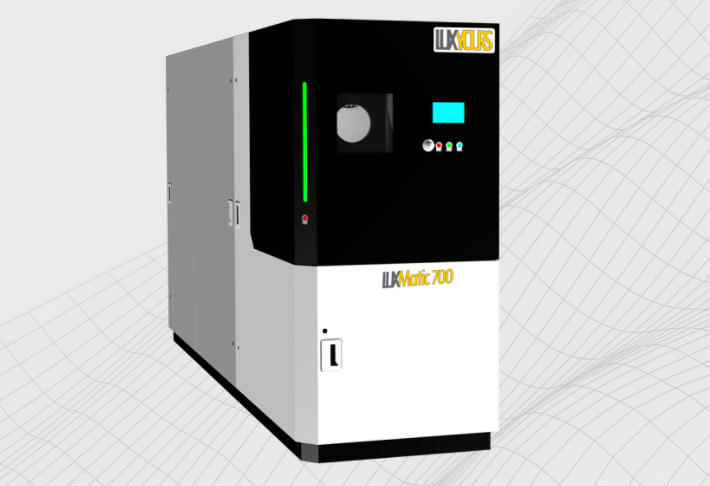

The LUXMatic 700 post-processing machine

Adding to its existing services portfolio, LuxYours has now launched its first post-processing unit: the LUXMatic 700. Leveraging the company’s IFS technology, the system is reportedly capable of smoothening the most filigree parts, while reducing cavities and displaced drops of material which can affect surface finish.

The LuxMatic 700 uses a custom-designed acid mixture to create its chemical vapor, which after multiple utilizations, can be neutralized and disposed of in an environmentally-friendly way. LuxYours’ new machine also comprises a large processing chamber, making it capable of finishing parts up to 700x500x500mm in size, within just 65 minutes.

When LuxYours initially started to accept pre-orders for the LuxMatic 700, it had only developed a post-processing technique, but the design of its machine hadn’t yet been finalized. For Pfefferkorn, the recently-accepted patent application combined with the launch of the firm’s first machine has vindicated the trust shown in the company by its early supporters.

“At that time we only had a process and an idea of how our LUXMatic 700 should look and function, but we still had an extensive machine development project to go. We are therefore all very pleased to be able to confirm the confidence placed in us,” said Pfefferkorn. “We also congratulate our visionary customers, who are now the first to operate the fastest and most economical machine for chemical smoothing of polyamide and TPU parts.”

A growing number of post-processing options

As companies continue to find new end-use applications for 3D printed parts, post-processing is increasingly being viewed as a more important part of additive manufacturing. As a result, a number of 3D printing firms have developed their own variations of chemical smoothing technology and sought to patent them in recent years.

AMT gained a patent for its Chemical Vapor Finishing process in July 2020. Working with the Danish Technological Institute, the company also earned EU certification to use its technology for applications in food and skin contact-related industries.

PostProcess Technologies has been granted a patent for its Submersed Vortex Cavitation technology. The company now holds more than 50 patents, including those for hardware, software, and proprietary chemicals.

Elsewhere, Quintus Technologies is developing its own High-Pressure Heat Treatment Technology, to completely finish 3D printed parts within one machine. Unifying the process reportedly yields components with enhanced strength and fatigue resistance characteristics.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the company’s LuxMatic 700 system, which features its patented IFS process. Image via LuxYours.