3D printing technology developer Freemelt has unveiled a new patent-pending method of preheating the powder bed in Electron Beam Powder Bed Fusion (E-PBF) 3D printers, called ProHeat.

Currently under development, ProHeat will be integrated into Freemelt’s future 3D printing systems to widen the scope of E-PBF processable materials.

“We are very optimistic about this innovation,” said Ulric Ljungblad, Freemelt CEO. “ProHeat is an enabler for robust, efficient processing and expands the potential of E-PBF to new classes of materials that are difficult or even impossible to process in E-PBF systems as of today.”

Benefits of ProHeat

Utilizing a heating device positioned above the powder bed, ProHeat uses electromagnetic radiation to sinter the powder layers smoothly and evenly. Because the method doesn’t expose the powder particles to an electrical charge, due to the preheating taking place without interaction with electrons, the risk of so-called smoke events is greatly reduced.

According to Freemelt, ProHeat provides fast and efficient heating while maintaining high vacuum purity and beam quality. Costly inert gases such as helium and argon are not consumed during the process, and the method is considered substantially less time-consuming than some existing E-PBF preheating methods.

“ProHeat makes it possible to heat and sinter the powder bed in a gentle and uniform manner, without exposing it to electric charge,” said Ulf Ackelid, senior scientist at Freemelt. “This makes it much easier and more efficient to build parts from fine powders and from powders of poor conductivity. ProHeat will speed up development of new E-PBF materials since it eliminates the time-consuming optimization of preheating parameters.”

Electron Beam Powder Bed Fusion

Founded in 2017, Freemelt’s EBM 3D printer, the Freemelt One, was developed to aid research and development into metal materials for additive manufacturing.

Last year, Freemelt announced the completion of a SEK 15M ($1.6M) capital investment round led by venture capital firm Industrifonden to fuel the next phase of its growth in open-source electron beam melting (EBM) 3D printing technology. The firm recently made it onto the yearly ’33-list’, which flags the most innovative and promising Swedish start-ups from 2020.

Originally, fellow Sweden-based 3D printer manufacturer Arcam was the first company to build an EBM system, although other several companies, including Freemelt, have since expanded into this space.

One of the more recent examples is UK-based engineering firm Wayland Additive, which announced the development of its new E-PBF technology, NeuBeam, earlier this year. Shortly after, the firm announced it planned to launch its first industrial 3D printer, the Calibur 3, on January 27, 2021. The machine will be the first to feature the company’s NeuBeam technology which it claims will feature several advantages over existing manufacturing processes.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

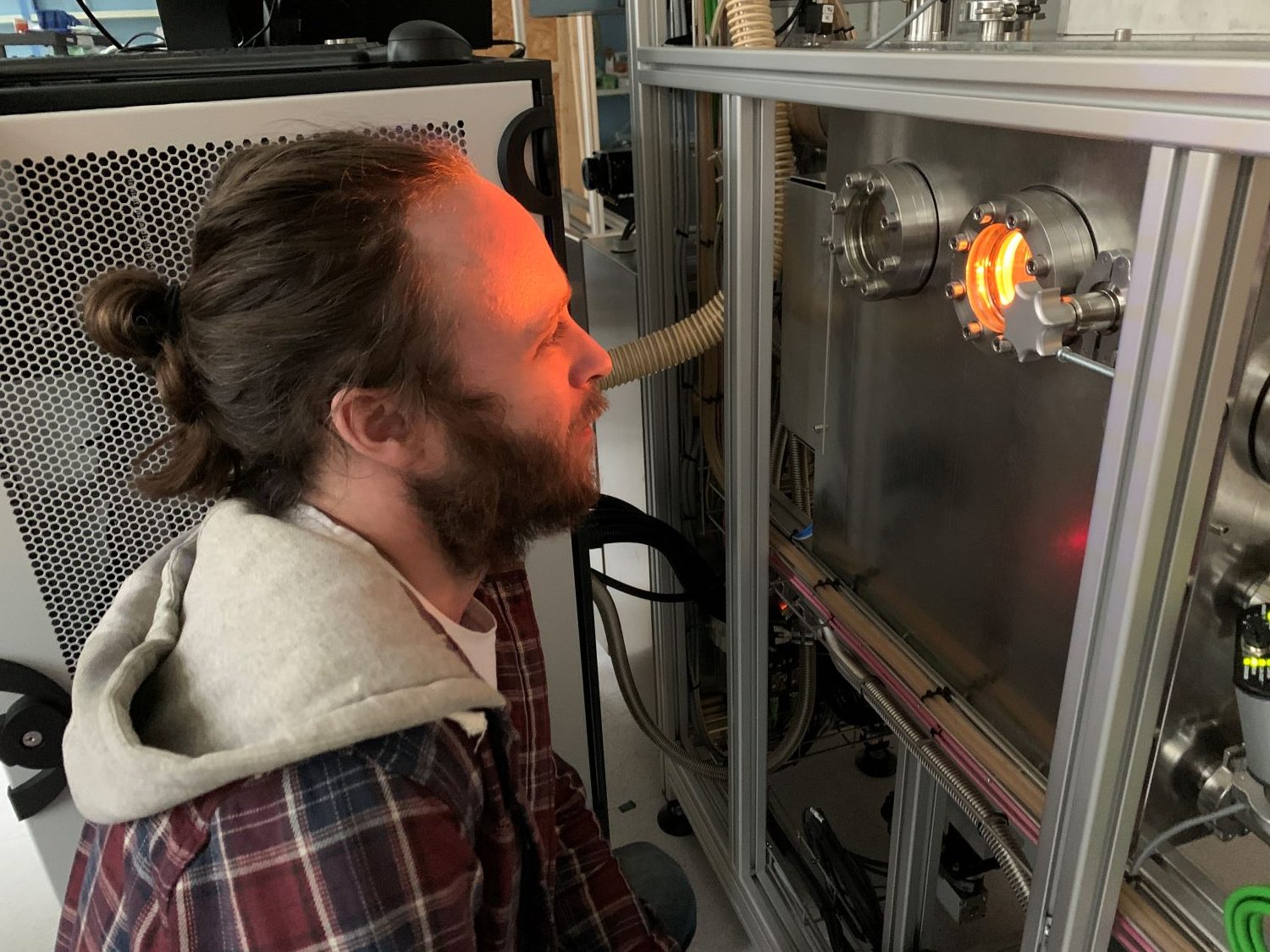

Featured image shows Freemelt’s ProHeat electron beam powder bed fusion preheating technology in progress. Image via Freemelt.